Method for preparing target for copper conductor of thin film transistor (TFT)-liquid crystal display (LCD) array substrate, and target

An array substrate and copper wire technology, applied in the field of sputtering targets, can solve problems such as unfavorable improvement in the quality of TFT-LCD array substrates, difficulty in controlling grain orientation, etc., and achieve high relative density, low film stress, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, a detailed description is given below in conjunction with the preferred embodiments of the present invention and the accompanying drawings.

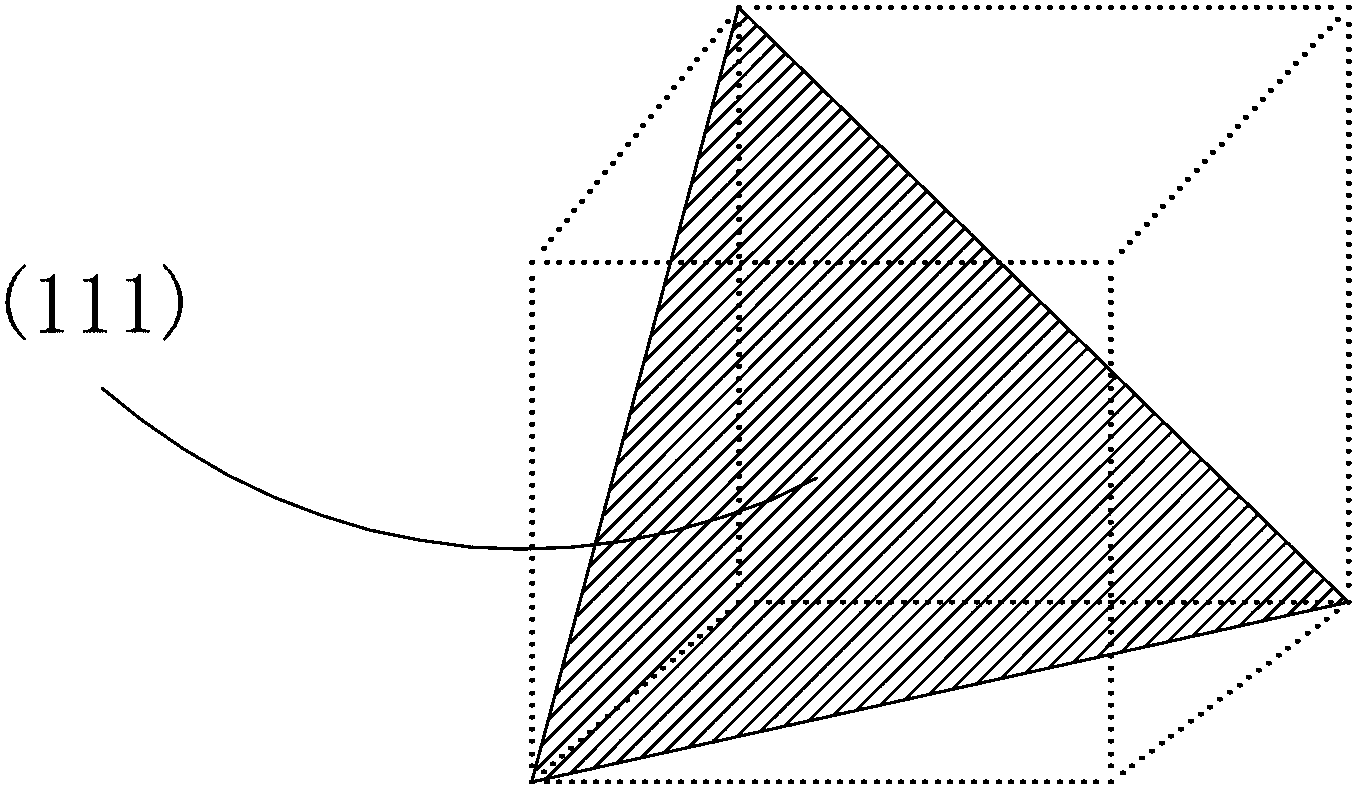

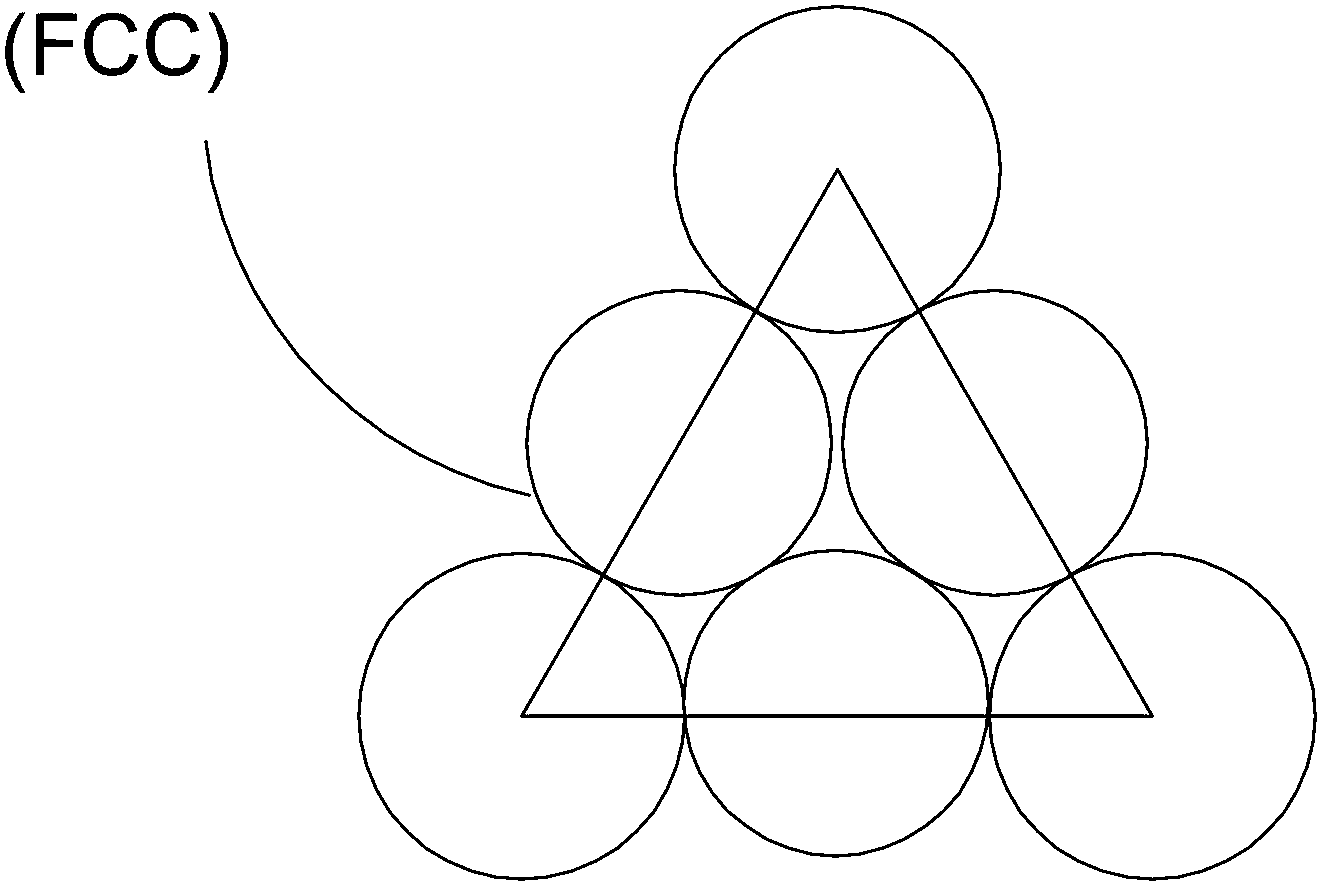

[0034] see Figure 2 to Figure 6 The present invention provides a method for preparing a target material for copper wires of a TFT-LCD array substrate, the method comprising the following steps:

[0035] Step 1. Provide copper powder and a spark plasma activation sintering device.

[0036] The quality of the copper powder is calculated according to the area and thickness of the copper thin film formed by predetermined sputtering. The purity of the copper powder can be specifically determined according to the properties of the copper film to be prepared. In this embodiment, the purity of the copper powder is 99.99%.

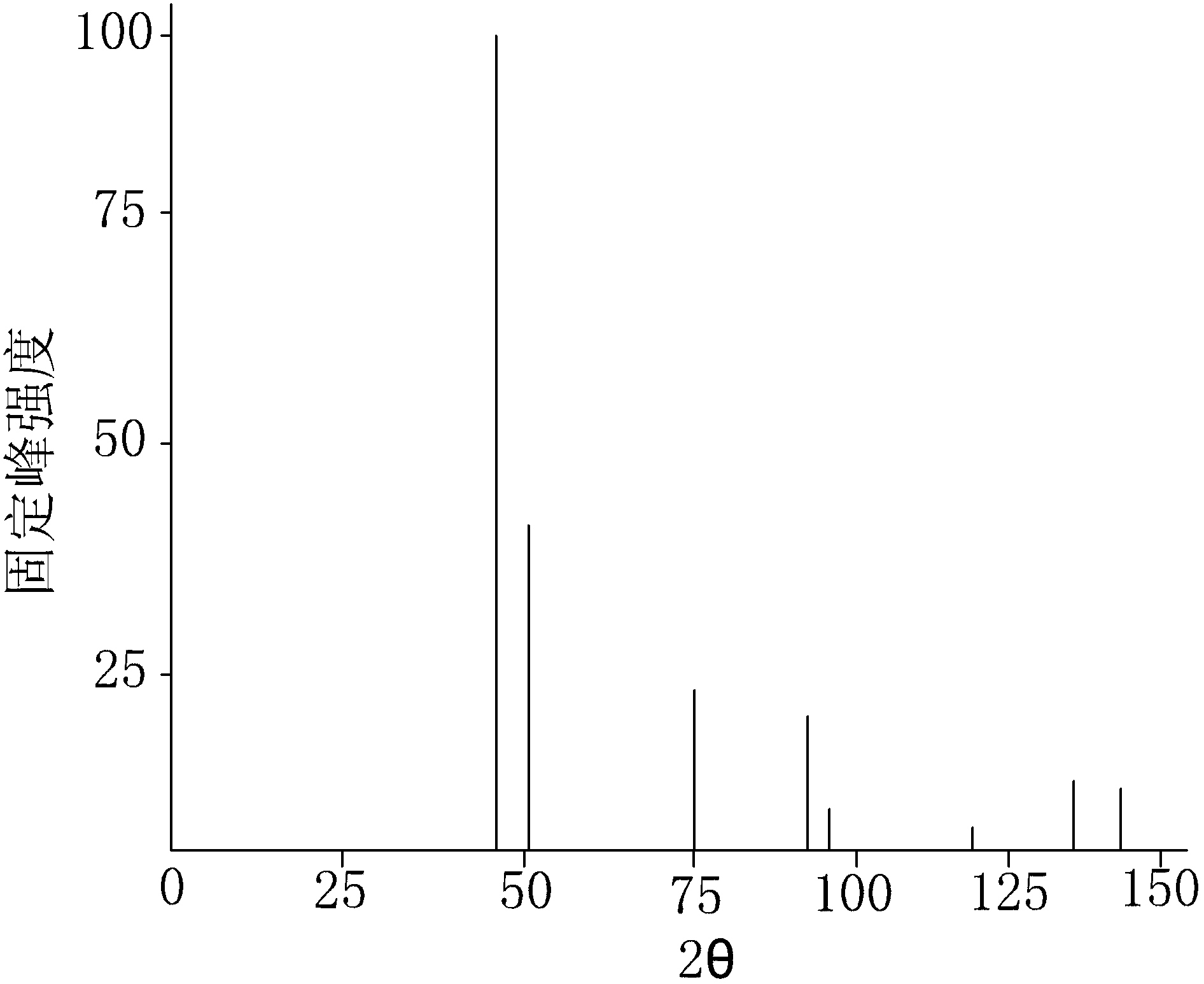

[0037] Step 2, adding the copper powder into a discharge plasma activation sintering device for sintering to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com