Method for transforming columnar crystal-orienting isometric crystal of directional solidified alloy with strong static magnetic field induction

A technology of directional solidification and static magnetic field, which is applied in self-solidification, chemical instruments and methods, single crystal growth, etc., and can solve problems such as complex equipment, difficulty in implementation, and contamination of molten metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) A lead-tin hypereutectic alloy whose alloy composition is Pb-80wt% Sn is selected. The purity of Pb and Sn are both 99.99%. After vacuum induction melting, the diameter is 3mm and the length is 20cm. Alloy rods, which are packaged in corundum tubes;

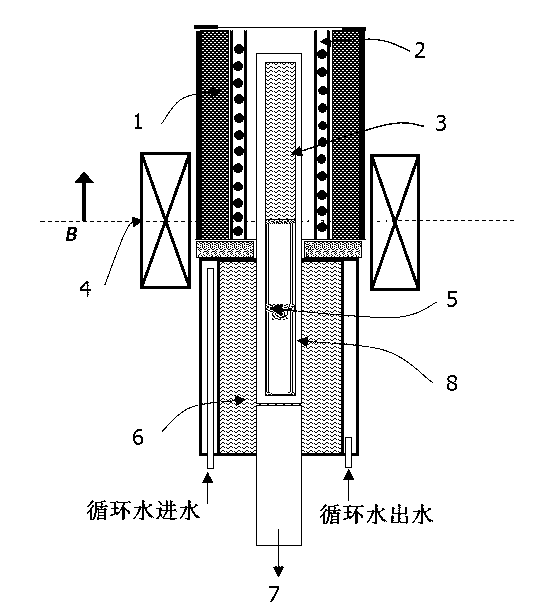

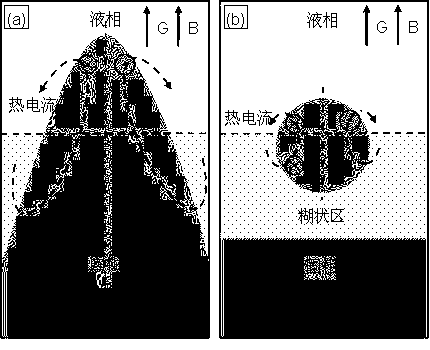

[0030](2) A directional solidification device using a typical Bridgman method (see figure 1 ), fix the above-mentioned corundum tube on the pull rod, and raise it into the heating furnace; adopt the longitudinal strong static magnetic field generated by the superconducting strong magnet, make the solid-liquid interface of the sample be in the stable magnetic field area, and control the magnetic field intensity to 12T (special Tesla);

[0031] (3) Turn on the power and turn on the heating furnace to heat the alloy rod. The central temperature of the heating furnace is 600°C and keep it warm for 30 minutes. After measurement, it is found that the temperature gradient in front of the liquid-solid interface is 52K / cm; th...

Embodiment 2

[0032] Example 2: The process and steps in this example are exactly the same as those in Example 1 above, except that the alloy is Al-4.5wt% Cu hypoeutectic alloy; the central temperature of the heating furnace is 900°C; The speed is 10μm / s; the temperature gradient at the front of the solid-liquid interface of the sample in the furnace is 62.8K / cm; the magnetic field strength generated by the superconducting magnet is 10T.

Embodiment 3

[0033] Example 3: The process and steps in this example are exactly the same as those in Example 2 above, except that the alloy system is an Al-7wt% Si hypoeutectic alloy; the central temperature of the heating furnace is 900°C, and the solid-liquid interface front of the sample The temperature gradient is measured as 40K / cm; the pulling speed of the rod is 120μm / s.

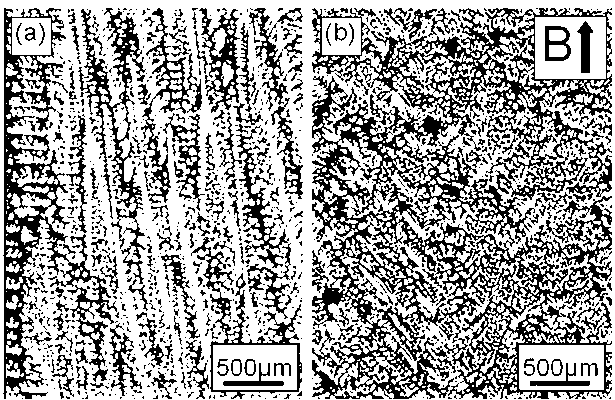

[0034] Microstructure Observation of Dendrites in Solidified Structure of Alloy Rod Samples

[0035] The sample obtained by directional solidification is cut symmetrically along the axial direction, and the sample near the solid-liquid interface is taken; it is ground and polished, and then corroded. The etchant used for the Pb-Sn alloy sample is a mixed solution of oxalic acid and hydrogen peroxide. The volume ratio is 3:1; the etchant used for Al-Cu and Al-Si alloy samples is H 2 O: HF mixed solution, the volume ratio of the two is water: HF=1000:5.

[0036] In order to make a comparison, during the detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com