Vinasse gelatinization degree detecting method

A detection method and a technology for gelatinization degree, which are applied in the field of winemaking, can solve the problems of reducing the utilization rate of starch, there is no accurate and effective detection method, and the wine yield is not high, so as to achieve low implementation cost, simple operation and improved utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

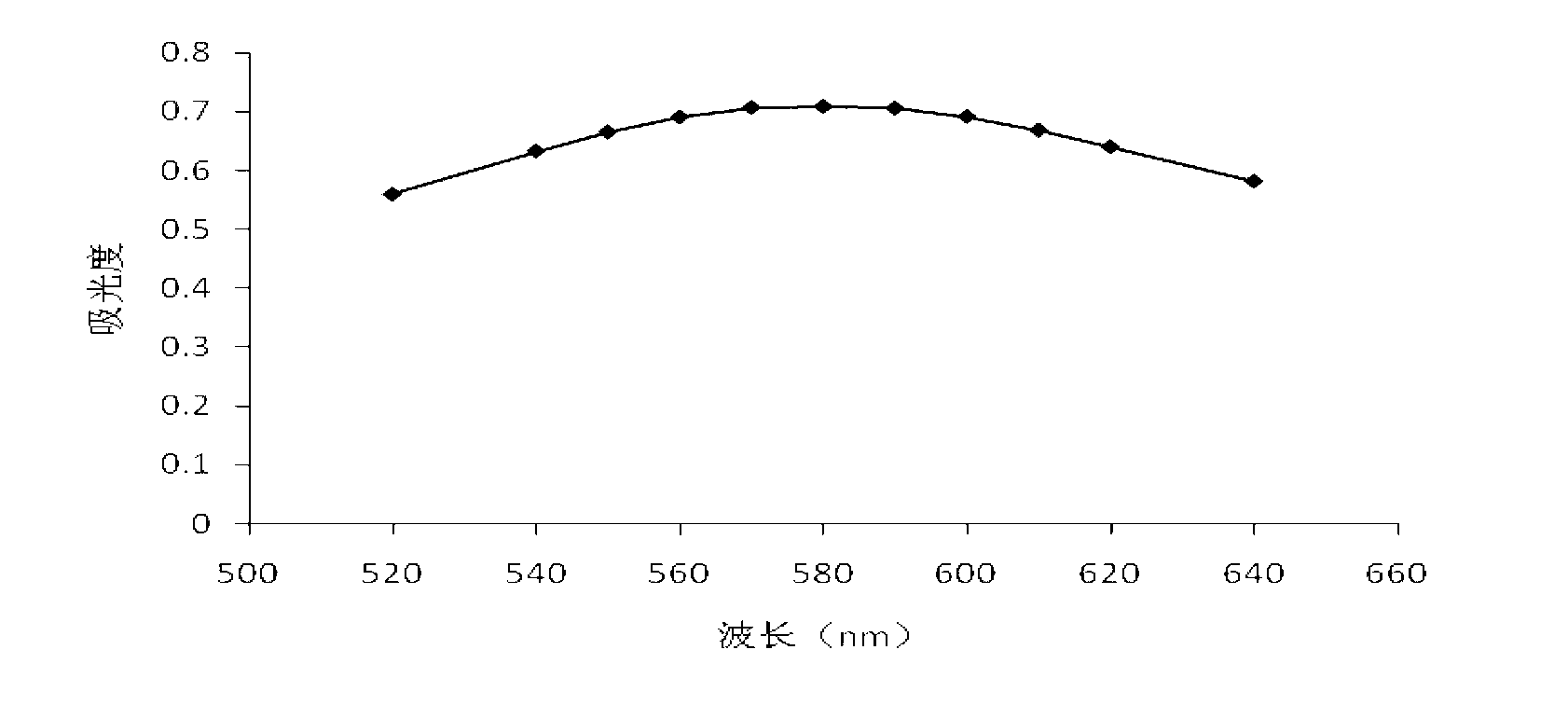

[0043] Embodiment 1 The selection of optimal detection wavelength

[0044] Mix the distiller's grains out of the cellar with grain and steam the wine for 1.5 hours. Weigh out 50 g of distiller's grains from the retort and mix them evenly. Stir them evenly in 200 mL of distilled water. Adjust the pH to 7. Put them in a retort and heat to reflux for 1.5 hours to make a fully gelatinized sample. Filter the sample solution, wash the filter residue three times with 50 mL of hot distilled water, combine the filtrate and washing liquid, and add distilled water to make up to 500 mL. Take 1 mL of the filtrate after constant volume, add appropriate amount of distilled water and shake well, then add 5 mL of 0.05 mol / L I-KI reagent, and make the volume to 100 mL. Use a spectrophotometer to detect the absorbance of the sample at 520-640 nm ( figure 1 ). From figure 1 It can be seen that the peak value of absorbance is 0.708, and the corresponding absorption wavelength is 580nm, so 580nm...

Embodiment 2

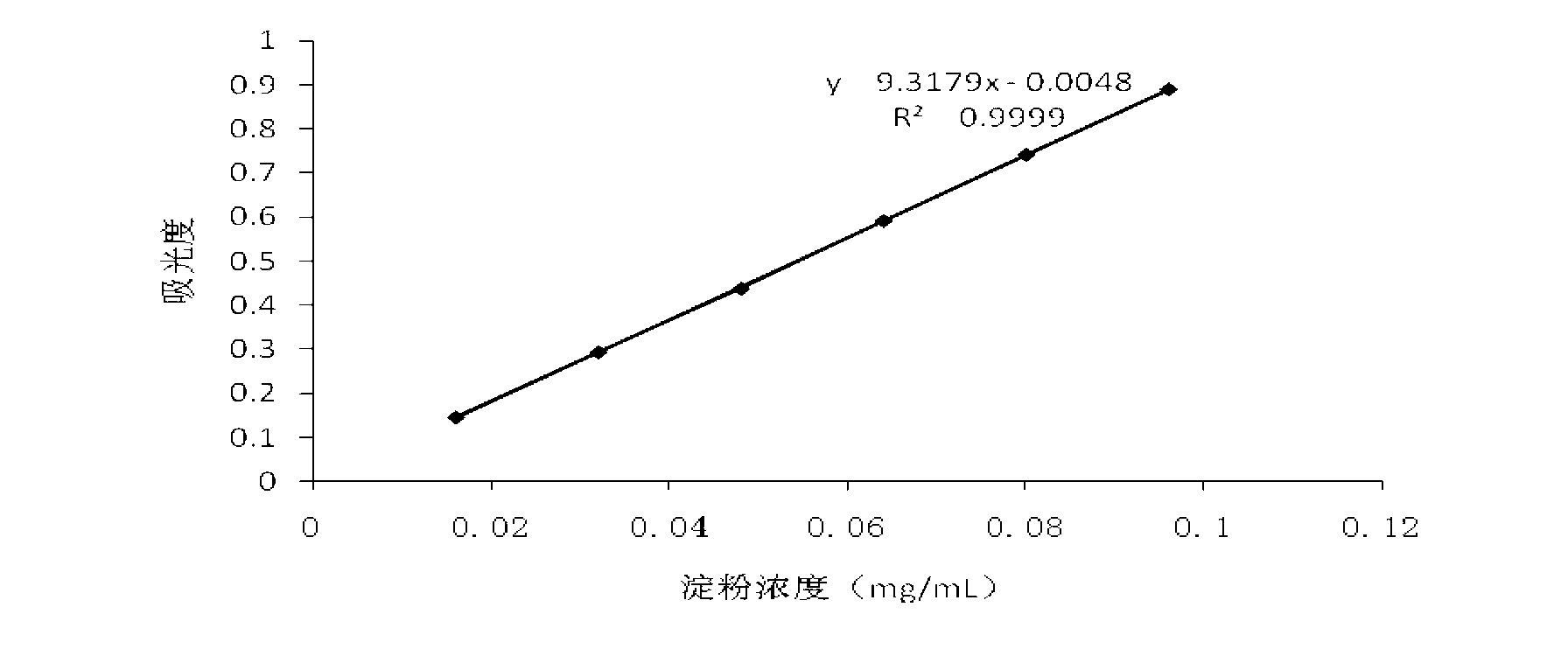

[0045] Embodiment 2 Drawing of standard curve

[0046] Prepare 2mg / mL starch standard solution, accurately pipette 0, 2, 4, 6, 8, 10, 12, 15mL respectively into a 25mL volumetric flask, dilute to volume with distilled water, and shake well. Take 1mL solution from the constant volume solution and add 9mL distilled water, then add 0.5mL iodine-potassium iodide solution, take the blank sample (9mL distilled water + 0.5mL iodine-potassium iodide solution) as a reference, and measure the absorbance of the sample solution at 580nm . The standard curve was obtained by plotting the absorbance against the starch concentration (see figure 2 ): Y=9.3179X-0.0048, correlation coefficient R 2 =0.9999.

Embodiment 4

[0049] Example 4 Using the present invention to detect the degree of gelatinization of distiller's grains

[0050] Mix the distiller's grains out of the cellar with grain, put them in a steamer, steam distill at 0.01-0.02 MPa for 1 hour, take out 100 g of distiller's grains from the retort and mix them well, divide the sample into two parts of equal mass, 50 g each, numbered 1 and 2 respectively. Add sample 1 to 200mL distilled water, stir evenly and adjust the pH to 7, ultrasonically shake for 30 minutes to break sample 1, so that the gelatinized starch molecules are fully dispersed in the aqueous solution; add sample 2 to 200mL distilled water, stir evenly and adjust the pH to 7 , placed in a retort and heated to reflux for 2 hours to make a fully gelatinized sample. Filter sample solutions 1 and 2, and wash the filter residue with 50 mL of hot distilled water for 3 times. After combining the filtrates from 4 times, add distilled water to both sample solutions to 500 mL. Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com