Method for ultrasonic-assisted hydrothermal restoration of lithium cobalt oxide material in spent lithium ion battery

A technology of lithium-ion batteries and lithium cobalt oxide, which is applied in the field of hydrothermal restoration of lithium cobalt oxide materials, and can solve the problems of secondary air pollution, strong corrosion of reaction equipment, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Mechanically disassemble the used lithium-ion mobile phone battery to obtain lithium cobalt oxide waste in the positive electrode material;

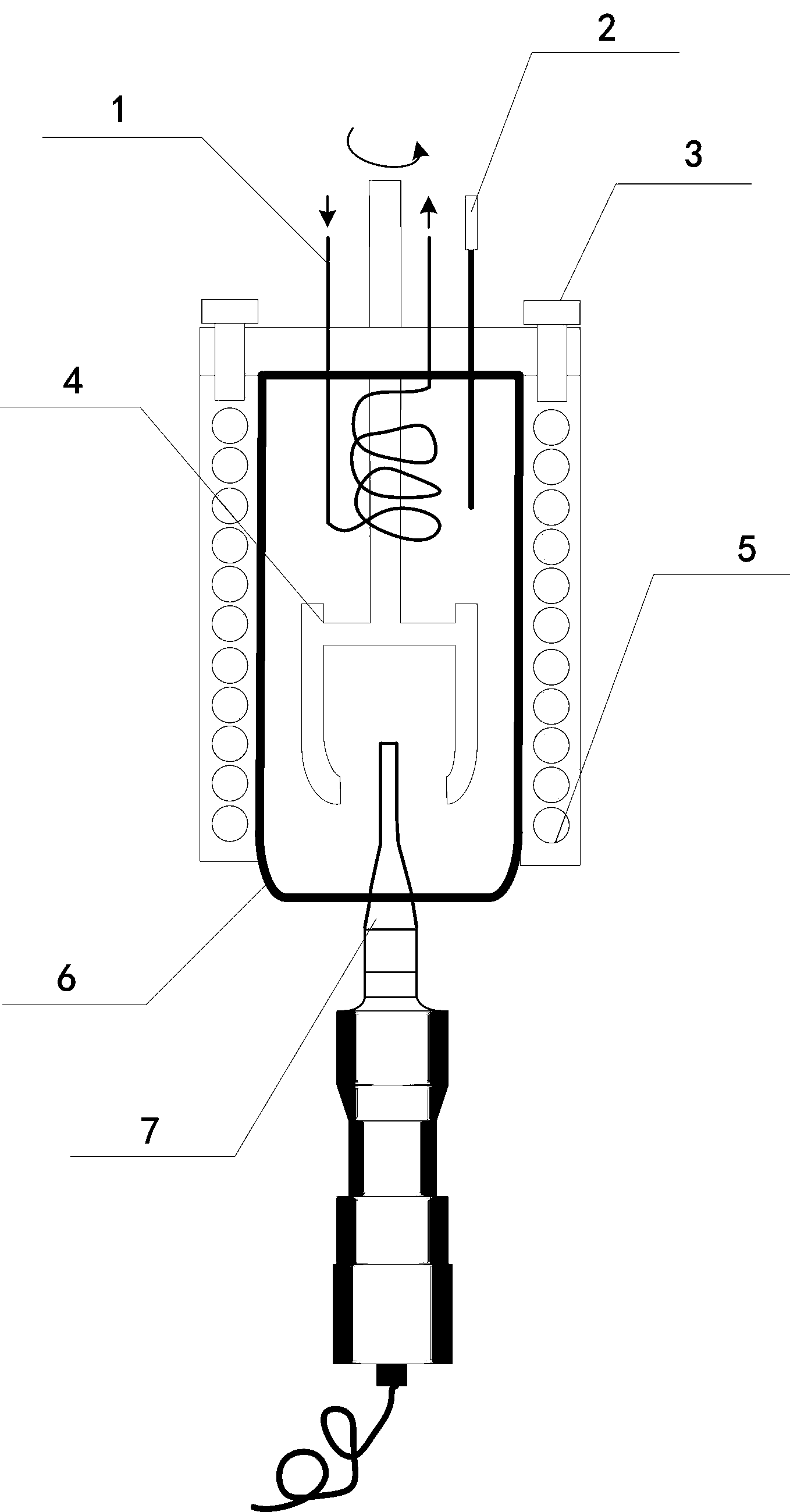

[0018] (2) Place lithium cobalt oxide waste in an ultrasonic-hydrothermal reactor filled with 2M lithium hydroxide solution. The ultrasonic-hydrothermal reactor is equipped with electric stirrer, electric heating device, temperature sensor, water cooling system, airtight Reactor, and an ultrasonic horn is installed at the bottom of the closed reactor, and the head of the ultrasonic horn is submerged under the liquid surface;

[0019] (3) The power of the ultrasonic equipment is 650 W, the ultrasonic frequency is 25 kHz, heated to 150°C, and cooled naturally after ultrasonication for 12 hours;

[0020] (4) When the ultrasonic reactor is cooled to room temperature, the lithium cobalt oxide material in the lithium hydroxide solution is filtered and washed with deionized water for 3 to 5 times;

[0021] (5) Lithium cobalt oxide m...

Embodiment 2

[0024] (1) Mechanically disassemble the used lithium-ion mobile phone battery to obtain lithium cobalt oxide waste in the positive electrode material;

[0025] (2) Place the lithium cobaltate waste in an ultrasonic hydrothermal reactor filled with 1M lithium hydroxide solution. The reactor is equipped with an electric heating device, a stirring device, a temperature control device, and a water flow cooling device, and is installed at the bottom of the reactor. Ultrasonic horn, the head of the horn is submerged under the liquid surface;

[0026] (3) The power of the ultrasonic equipment is 650 W, the ultrasonic frequency is 25 kHz, heated to 200°C, and cooled naturally after ultrasonication for 4 hours;

[0027] (4) When the ultrasonic reactor is cooled to room temperature, the lithium cobalt oxide material in the lithium hydroxide solution is filtered and washed with deionized water for 3 to 5 times;

[0028] (5) Lithium cobalt oxide material obtained by filtration, dried in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com