Natural super-hydrophilic porous TiO2/SiO2 composite thin film and preparation method thereof

A super-hydrophilic, composite film technology, applied in the direction of solid-state chemical plating, coating, metal material coating technology, etc., can solve the problems of unsatisfactory super-hydrophilic performance and achieve the effect of improving super-hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

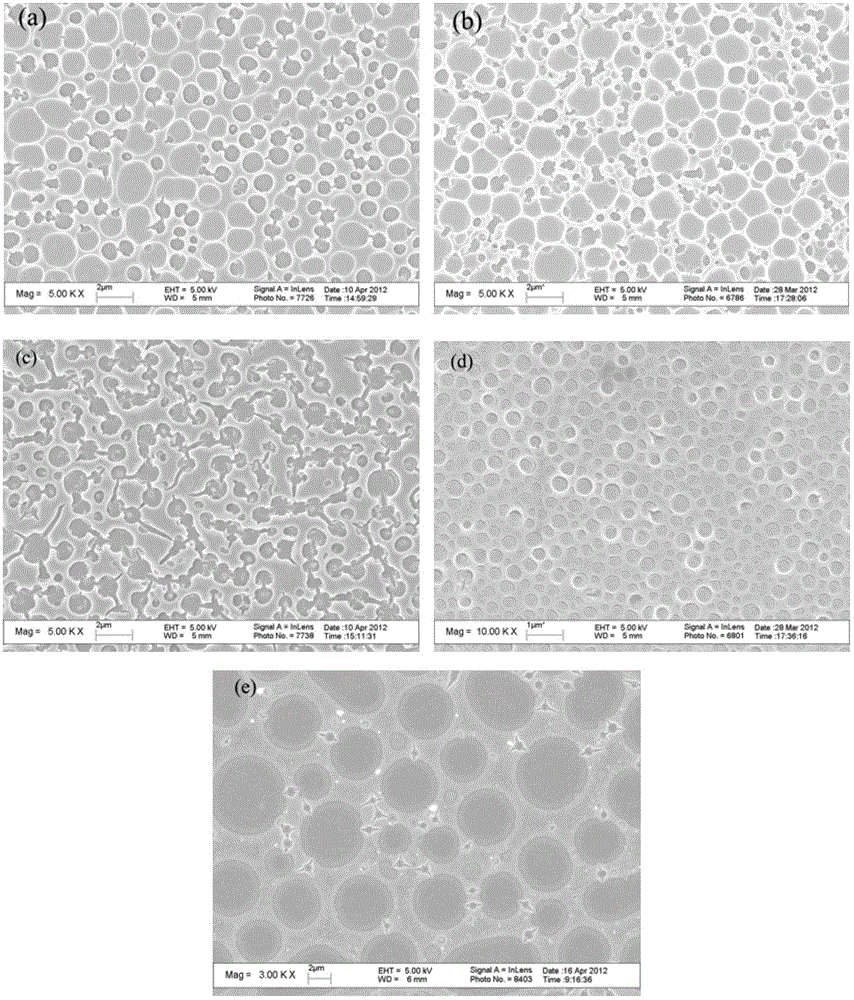

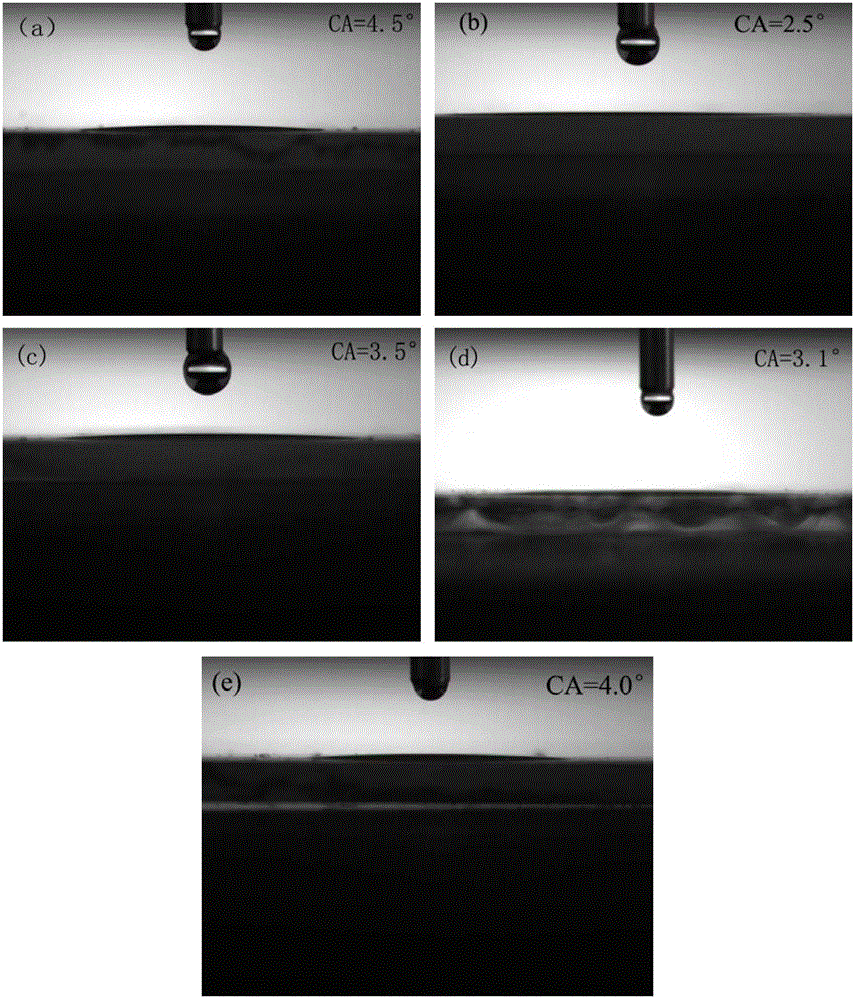

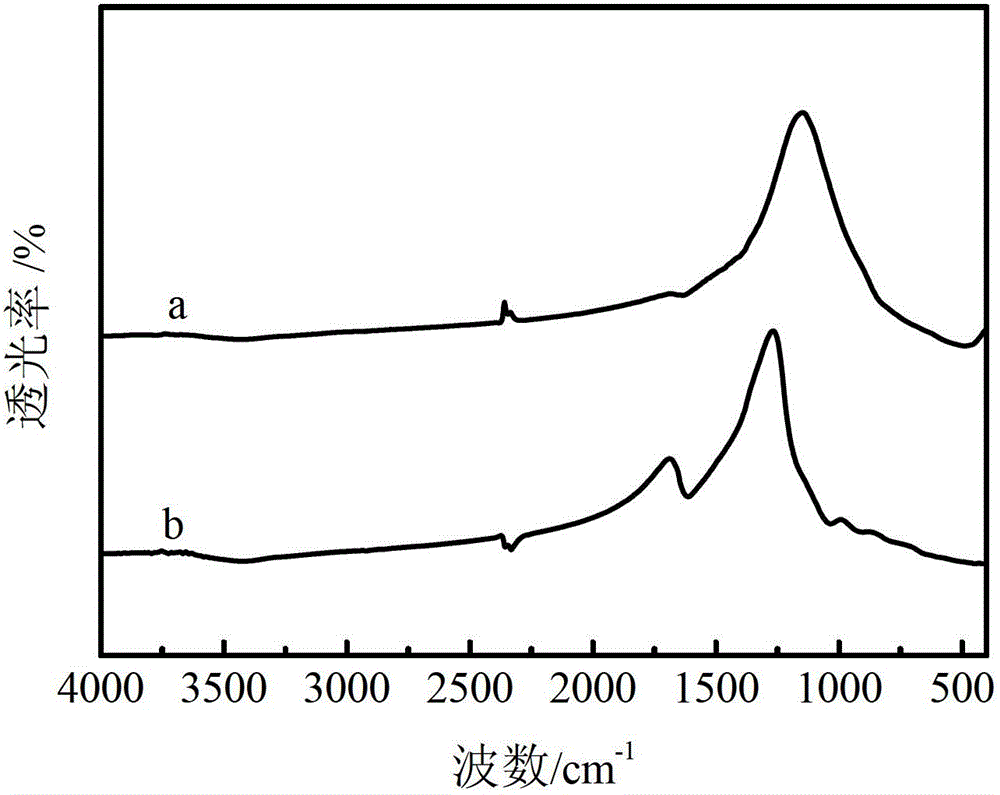

Embodiment 1

[0027] At room temperature of 25°C, mix 10ml of tetraethyl orthosilicate and 40ml of absolute ethanol and stir for 30 minutes to make a stock solution (referred to as solution B): mix 20ml of absolute ethanol, 2.5ml of deionized water, 1ml of concentrated nitric acid (weight The fraction is about 65%, the same below) and mixed thoroughly to form a drop solution (referred to as solution A). Add solution A dropwise to solution B under strong stirring, continue to stir for 2 hours after the dropwise addition, and then seal and age for about 48 hours in the dark to form a stable SiO 2 Sol.

[0028] At room temperature of 25°C, mix 10ml of tetrabutyl titanate and 40ml of absolute ethanol and stir for 30min, then add 2ml of acetylacetone and 1.5ml of diethanolamine as a complexing agent for titanium alkoxide, fully mix all the added solutions, and prepare Make stock solution (denoted as D solution); 20ml absolute ethanol, 10ml deionized water, 1ml concentrated nitric acid are fully...

Embodiment 2

[0032] At 40°C, mix 10ml of tetraethyl orthosilicate and 40ml of absolute ethanol and stir for 30 minutes to prepare a stock solution (referred to as solution B): fully mix 20ml of absolute ethanol, 2ml of deionized water, and 0.5ml of concentrated nitric acid. Dubbed drop solution (referred to as A solution). Add solution A dropwise to solution B under strong stirring, continue to stir for 2 hours after the dropwise addition, and then seal and age for about 48 hours in the dark to form a stable SiO 2 Sol.

[0033] At 40°C, mix 10ml of tetrabutyl titanate and 40ml of absolute ethanol and stir for 30min, then add 2ml of acetylacetone and 0.5ml of ethanolamine as a complexing agent for titanium alkoxide, fully mix all the added solutions, and make a stock solution (referred to as D solution); 20ml of absolute ethanol, 10ml of deionized water, and 0.5ml of concentrated nitric acid are fully mixed to form a drop solution (referred to as C solution). Add solution C dropwise to so...

Embodiment 3

[0040] At 60°C, mix 10ml of tetraethyl orthosilicate and 30ml of absolute ethanol and stir for 30 minutes to make a stock solution (referred to as solution B): fully mix 20ml of absolute ethanol, 5ml of deionized water, and 1.5ml of concentrated nitric acid. Dubbed drop solution (referred to as A solution). Add solution A dropwise to solution B under strong stirring, continue to stir for 2 hours after the dropwise addition, and then seal and age for about 48 hours in the dark to form a stable SiO 2 Sol.

[0041] At 60°C, mix 10ml of tetrabutyl titanate and 40ml of absolute ethanol and stir for 30min, then add 2ml of acetylacetone and 4ml of triethanolamine as a complexing agent for titanium alkoxide, fully mix all the added solutions, and make a stock solution (referred to as D solution); 20ml of absolute ethanol, 10ml of deionized water, and 1.5ml of concentrated nitric acid were fully mixed to form a dropwise solution (referred to as C solution). Add solution C dropwise to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com