Oleophylic fertilizer for bioremediation of oil polluted environment and method for preparing oleophylic fertilizer

A technology for bioremediation and oil pollution, applied in the field of oil pollution environmental control, can solve problems such as inappropriate bioremediation, and achieve the effects of improving bioavailability, promoting bioremediation, and eliminating oil films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of lipophilic fertilizer with urea as nitrogen source

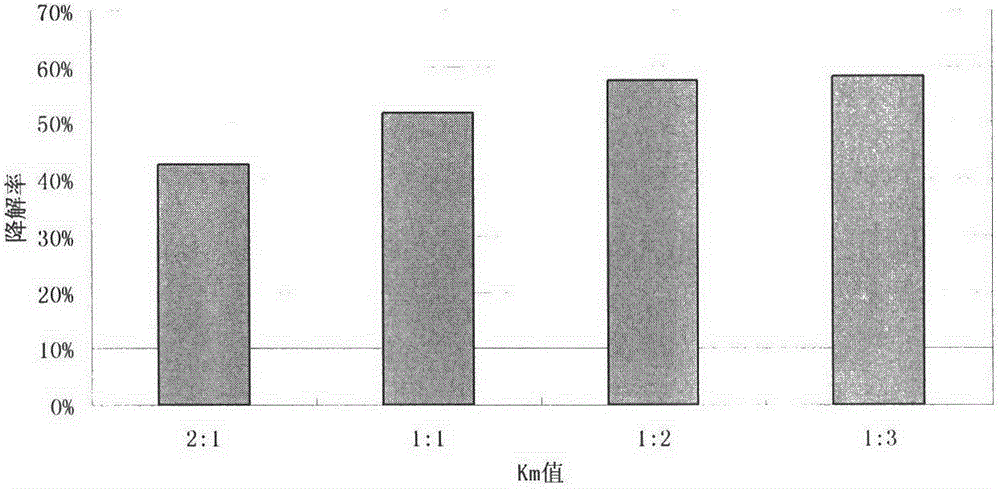

[0034] Prepare a mixture of soybean lecithin and co-emulsifier according to the mass ratio (Km value) of 1:2, heat at 75°C for 10 min, vortex mix for 2 min, and dissolve in ultrasonic for 10 min, weigh oleic acid and the co-emulsifier according to the mass ratio of 3:7 2 g of the mixture was vortexed for 15 min to mix well. Add 600 μl of saturated urea solution, vortex and mix for 10 minutes, and then let it stand for about 30 minutes to balance and form a water-in-oil microemulsion. Sealed and stored to get the product.

Embodiment 2

[0035] Example 2 Adding lipophilic fertilizers to oil-polluted seawater and observing the state of the oil with a microscope

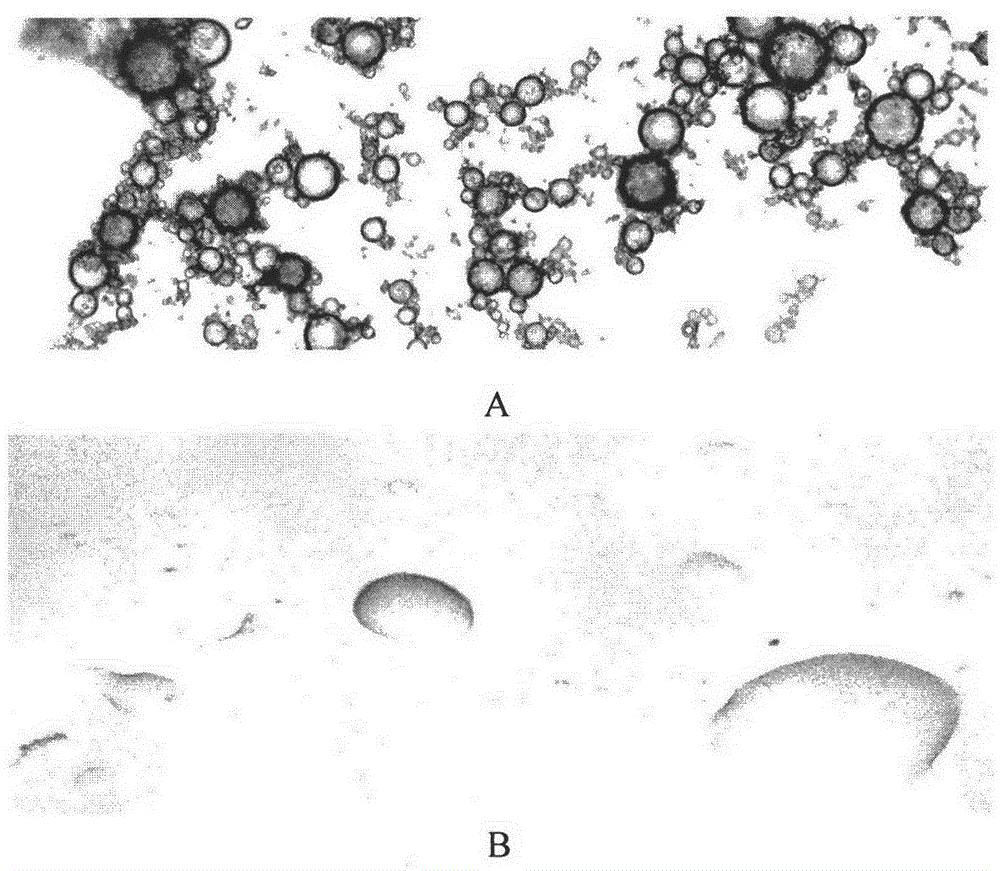

[0036] Get 50ml seawater sample in the Erlenmeyer flask of 150ml, add 0.5ml diesel oil respectively, one bottle adds the lipophilic fertilizer 100 μ l prepared in embodiment 1, another bottle does not add, after shaking at 100rpm rotating speed simultaneously 12h, get sample in Observed under a microscope, under the magnification of 100 times, the state of diesel oil is as follows: figure 1 As shown, the oleophilic fertilizer makes the oil film form small oil droplets and aggregate, and at the same time attach to the oil.

Embodiment 3

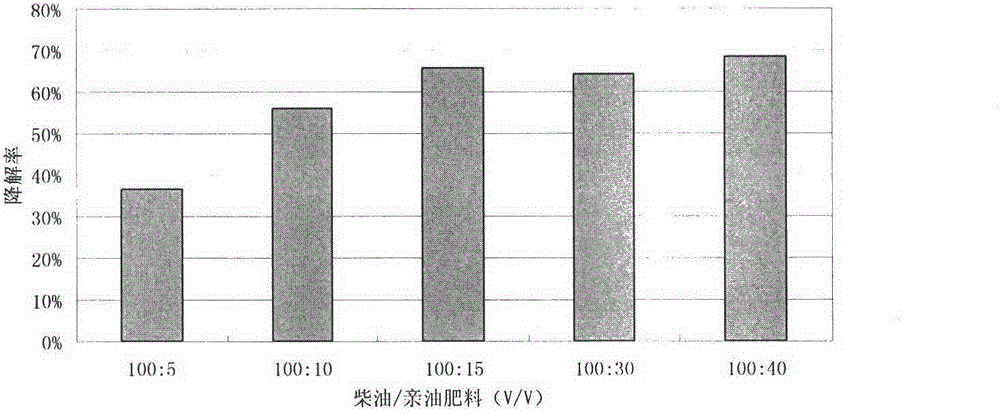

[0037] Example 3 The promotion of lipophilic fertilizers to the degradation of diesel by strains

[0038] Four strains of diesel-oil-degrading bacteria isolated from oil-polluted seawater were cultured overnight in LB medium, then the bacteria were collected and inoculated into 150ml Erlenmeyer flasks containing 50ml of seawater samples, and 0.5ml of diesel oil was added to each bottle. 100 μl of the lipophilic fertilizer prepared in Example 1 was not added to the other bottle. After culturing in a shaker at 30° C. and 180 rpm for 4 days, the degradation rate of diesel oil was measured. The degradation rate of diesel oil was only 8% without adding lipophilic fertilizer, but it reached 64% under the condition of adding lipophilic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com