Water-soluble polyether hardening agent

A technology of water-soluble polyether and quenching agent, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., to achieve uniform heat dissipation, reduce internal stress, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Water-soluble polyether quenching agent of the present invention, its chemical composition is by weight: water-soluble polyether: ethylene glycol: sebacic acid: monoethanolamine: sodium nitrate: sodium chloride=45:15:8:8: 8:16.

[0018] When in use, the water-soluble polyether quenching agent of the present invention is diluted with water to form a composition by weight percentage: water-soluble polyether 3%, ethylene glycol 1%, sebacic acid 0.53%, sodium nitrate 0.53%, sodium chloride 1.06% solution, while adding 1% antirust agent F731 and 1% preservative sodium nitrite accounting for the weight of the solution.

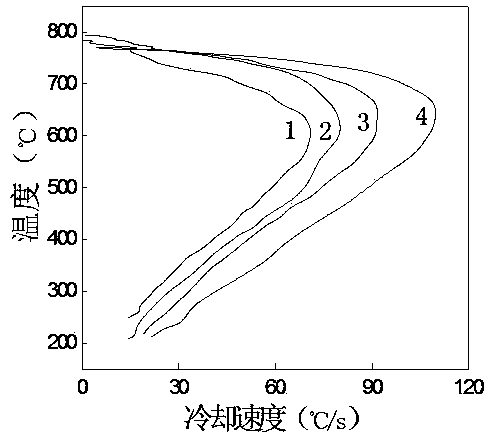

[0019] The cooling rate for quenching gear steel by using it is as follows: figure 1 Shown in curve 1.

Embodiment 2

[0021] Water-soluble polyether quenching agent of the present invention, its chemical composition is by weight: water-soluble polyether: ethylene glycol: sebacic acid: monoethanolamine: sodium nitrate: sodium chloride=45:15:8:8: 8:16.

[0022] When in use, the water-soluble polyether quenching agent of the present invention is diluted with water to form a composition by weight percentage: water-soluble polyether 5%, ethylene glycol 1.7%, sebacic acid 1.12%, sodium nitrate 1.12%, sodium chloride 2.25% solution, and add rust inhibitor F731 accounting for 0.5% by weight of the solution at the same time.

[0023] The cooling rate for quenching gear steel by using it is as follows: figure 1 Shown in curve 2.

Embodiment 3

[0025] Water-soluble polyether quenching agent of the present invention, its chemical composition is by weight: water-soluble polyether: ethylene glycol: sebacic acid: monoethanolamine: sodium nitrate: sodium chloride=45:15:8:8: 8:16.

[0026] When in use, the water-soluble polyether quenching agent of the present invention is diluted with water to form a composition by weight percentage: water-soluble polyether 8%, ethylene glycol 2.7%, sebacic acid 1.42%, sodium nitrate 1.42%, sodium chloride 2.84% solution, add the antiseptic sodium nitrite that accounts for 0.5% solution weight simultaneously.

[0027] The cooling rate for quenching gear steel by using it is as follows: figure 1 Shown in curve 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com