Multi-wall carbon nano-tube carried core-shell silver-platinum cathode catalyst and preparation method

A technology of multi-walled carbon nanotubes and cathode catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of reducing catalytic efficiency and large catalyst particle size. , shedding and other problems, to achieve the effect of enhancing bonding, preventing reunion, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

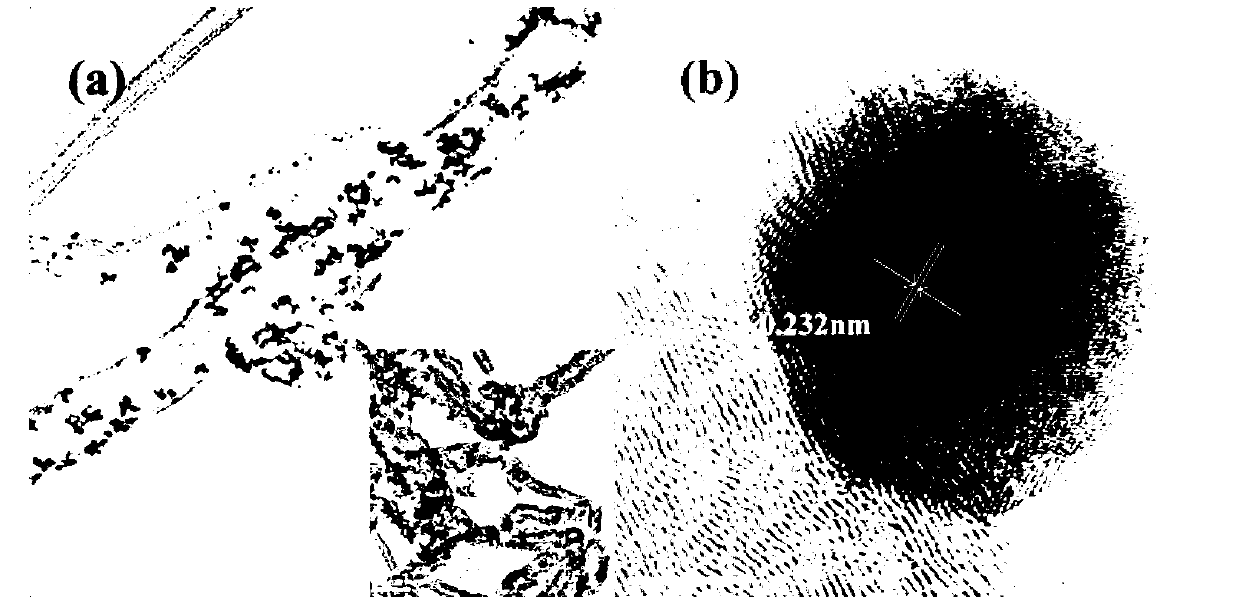

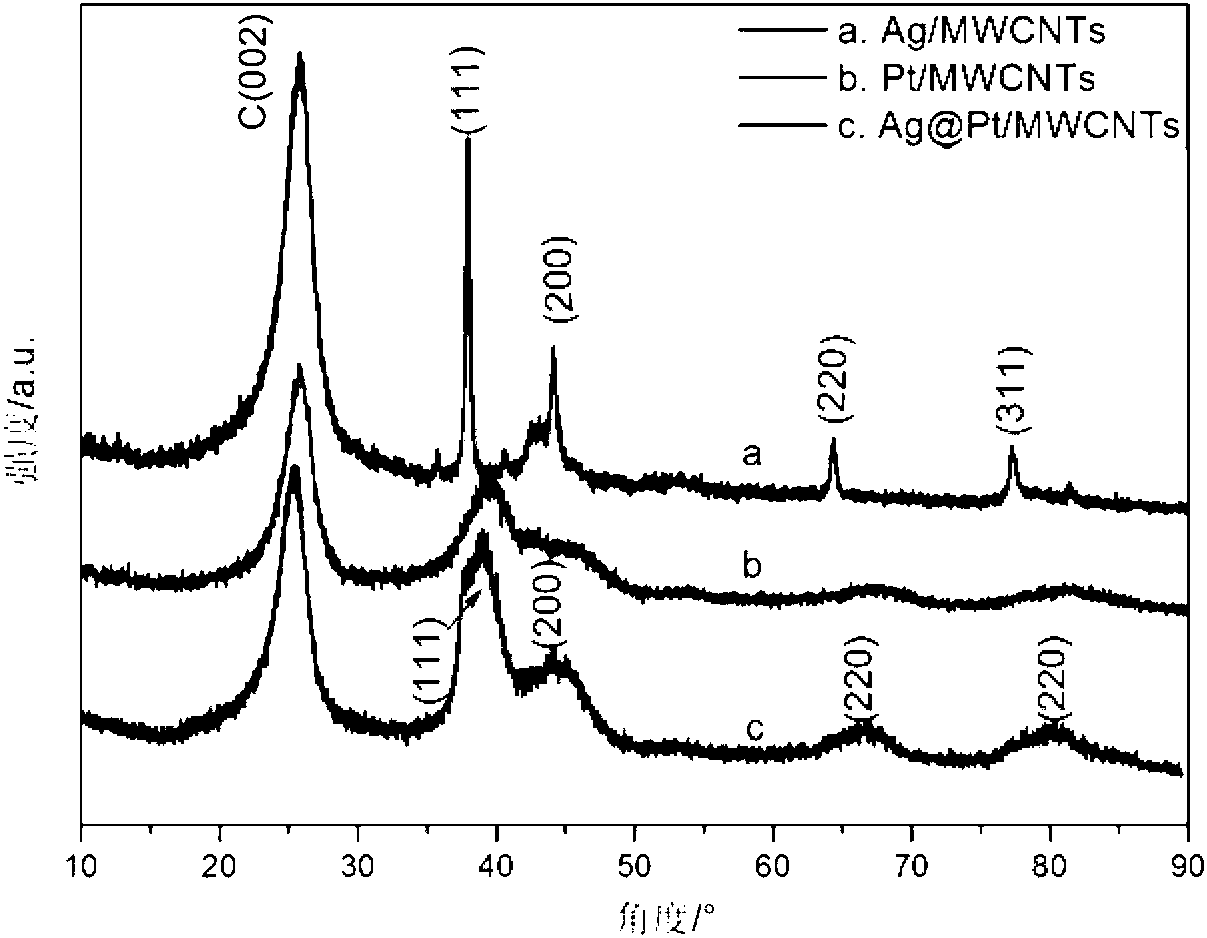

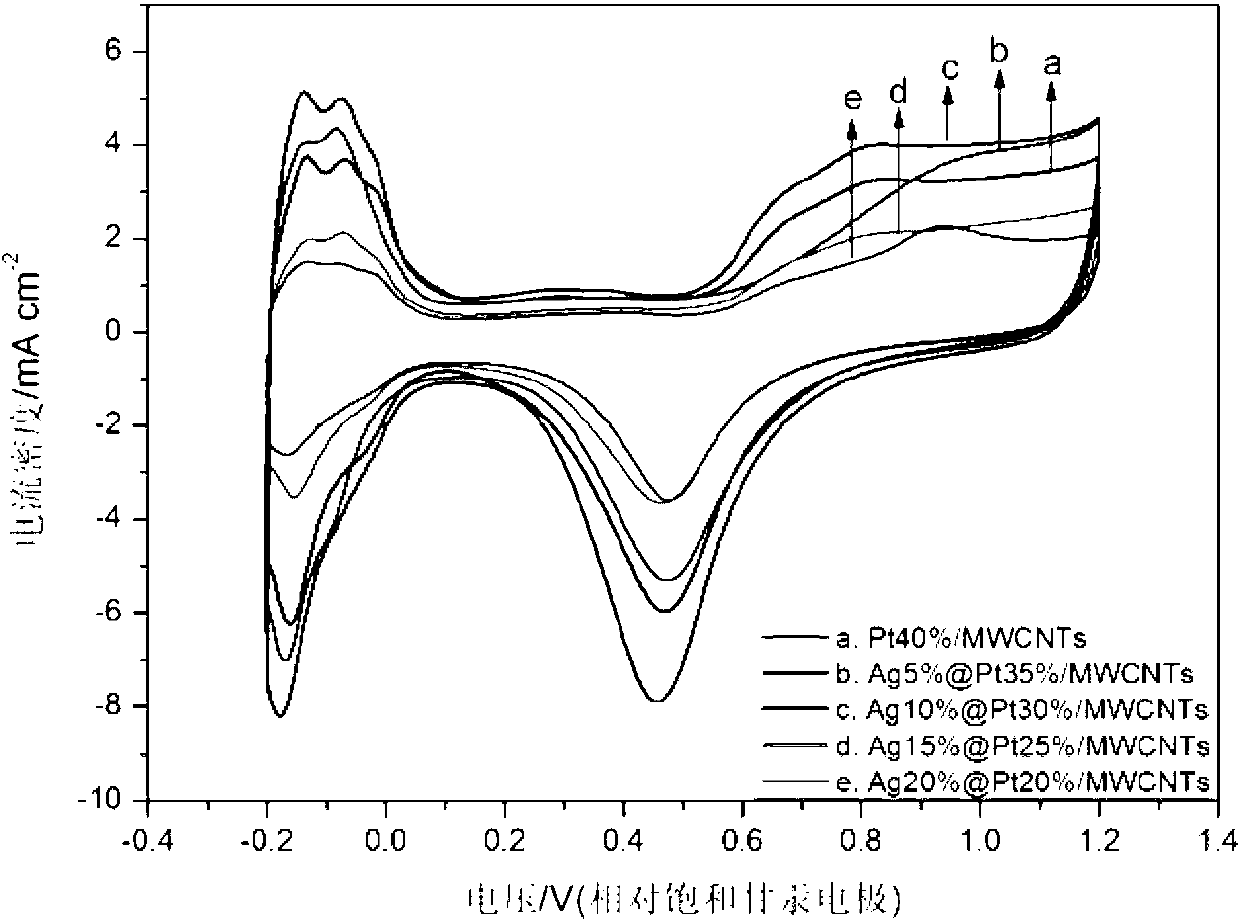

[0029] (1) Weigh 92.7 ml, 1 mmol / L of AgNO 3 The solution and 84.6 mg of sodium citrate were dissolved in ethanol / deionized water (preferred volume ratio 1:1). After complete dissolution, 120 mg of concentrated nitric acid-treated multi-walled carbon nanotubes were added, fully stirred, and mixed evenly;

[0030](2) Dissolve 7.9 mg of sodium borohydride in 9.3 ml of ethanol, and add dropwise to the above reaction solution, stir, and react at room temperature for 2 hours. After the reaction is completed, wash the reacted liquid, suction filter, and dry at 60 ° C. Dry to constant weight to obtain Ag particles loaded on multi-walled carbon nanotubes.

[0031] (3) 65 milligrams of products that take step (2) are fully dispersed in ethylene glycol solution, add 2.325 milliliters, 0.077 mol / liter of H 2 PtCl 6 ·6H 2 O and fully stirred, the pH value of the system was adjusted to 8 with potassium hydroxide ethylene glycol solution, the temperature was raised to 90°C with stirring,...

Embodiment 2

[0034] (1) Weigh 185 milliliters, 1 mmol / L of AgNO 3 The solution and 168.9 mg of sodium citrate were dissolved in ethanol / deionized water (preferred volume ratio 1:1). After complete dissolution, 120 mg of multi-walled carbon nanotubes treated with concentrated nitric acid were added, fully stirred, and mixed evenly;

[0035] (2) Take 15.7 mg of sodium borohydride and dissolve it in 18.5 ml of ethanol, and add it dropwise to the above reaction solution, stir, and react at room temperature for 2 hours. Dry to constant weight to obtain Ag particles loaded on multi-walled carbon nanotubes.

[0036] (3) 70 milligrams of products that take step (2) are fully dispersed in ethylene glycol solution, add 1.990 milliliters, 0.077 mol / liter of H 2 PtCl 6 ·6H 2 O and fully stirred, the pH value of the system was adjusted to 8 with potassium hydroxide ethylene glycol solution, the temperature was raised to 90°C with stirring, and the temperature was kept constant for 6 hours. During th...

Embodiment 3

[0039] (1) Weigh 278 milliliters, 1 mmol / L of AgNO 3 The solution and 253.8 mg of sodium citrate were dissolved in ethanol / deionized water (preferred volume ratio 1:1). After complete dissolution, 120 mg of multi-walled carbon nanotubes treated with concentrated nitric acid were added, fully stirred, and mixed evenly;

[0040] (2) Dissolve 23.6 mg of sodium borohydride in 27.8 ml of ethanol, and add dropwise to the above reaction solution, stir, and react at room temperature for 2 hours. After the reaction is completed, wash the reacted liquid, suction filter, and dry at 60°C. Dry to constant weight to obtain Ag particles loaded on multi-walled carbon nanotubes.

[0041] (3) 75 milligrams of products that take step (2) are fully dispersed in ethylene glycol solution, add 1.660 milliliters, 0.077 mol / liter of H 2 PtCl 6 ·6H 2 O and fully stirred, the pH value of the system was adjusted to 8 with potassium hydroxide ethylene glycol solution, the temperature was raised to 90°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com