Paint in aqueous epoxy thick paste and preparation method thereof

A water-based epoxy and paint technology, applied in the field of coatings, can solve the problems of environmental and human health hazards, high toxicity of intermediate paints, etc., and achieve the effects of no fire hazard, increased thixotropy, and good system sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

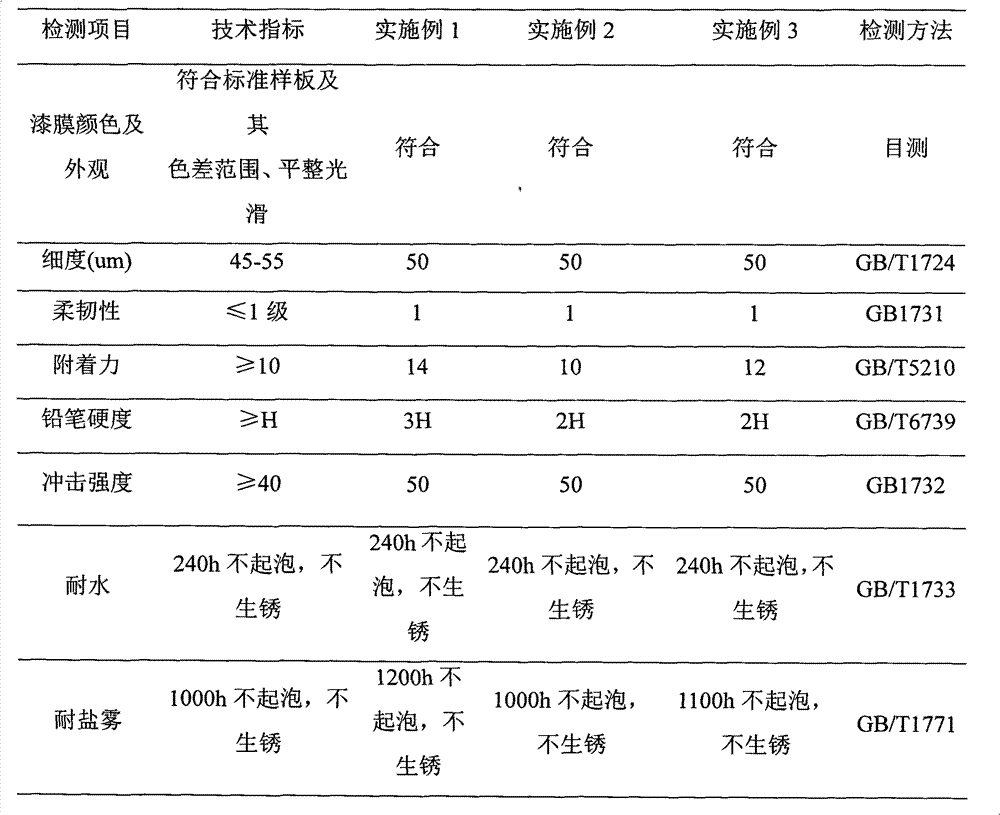

Examples

Embodiment 1

[0023] The water-based epoxy mastic medium coating provided in this embodiment 1 includes A component and B component, wherein, and the weight ratio of A component and B component is 5:1-3:1;

[0024] Component A is proportioned by weight, including: 15 parts of modified polyamine, 0.5 parts of co-solvent, 18.3 parts of distilled water, 1 part of anti-sedimentation thixotropic agent, 0.5 parts of defoamer, 40 parts of pigment and filler, and 1.5 parts of dispersant , 0.2 part of surfactant, 0.5 part of adhesion promoter, 0.5 part of thickener;

[0025] Component B is proportioned by weight, including: 20 parts of liquid epoxy resin and 2 parts of reactive diluent.

[0026] Further, the above-mentioned modified multi-component includes water-based fatty amine and water-based polyamide, and the weight ratio of water-based fatty amine and polyamide is 15:1-10:1. In this embodiment, specifically, the above-mentioned modified multi-component includes 13.6 parts of water-based fatt...

Embodiment 2

[0048] The water-based epoxy mastic medium coating provided in this embodiment 2 includes A component and B component, wherein, and the weight ratio of A component and B component is 5:1-3:1;

[0049] Component A is proportioned by weight, including: 24.5 parts of modified polyamine, 1.5 parts of co-solvent, 25 parts of distilled water, 6 parts of anti-sedimentation thixotropic agent, 0.5 part of defoamer, 45 parts of pigment and filler, and 1 part of dispersant , 0.2 part of surfactant, 0.3 part of adhesion promoter, 0.5 part of thickener;

[0050] Component B is proportioned by weight, including: 25 parts of liquid epoxy resin and 2.7 parts of reactive diluent.

[0051] Further, the above-mentioned modified multi-component includes water-based fatty amine and water-based polyamide, and the weight ratio of water-based fatty amine and polyamide is 15:1-10:1. In this embodiment, specifically, the above-mentioned modified multi-component includes 22.5 parts of water-based fatty...

Embodiment 3

[0069] The water-based epoxy mastic medium coating provided in this embodiment 3 includes A component and B component, wherein, and the weight ratio of A component and B component is 5:1-3:1;

[0070] Component A is proportioned by weight, including: 27.5 parts of modified polyamine, 2 parts of cosolvent, 30 parts of distilled water, 8 parts of anti-sedimentation thixotropic agent, 0.7 part of defoamer, 50 parts of pigment and filler, and 1.2 parts of dispersant , 0.3 part of surfactant, 0.5 part of adhesion promoter, 0.5 part of thickener;

[0071] Component B is proportioned by weight, including: 27 parts of liquid epoxy resin and 3 parts of reactive diluent.

[0072] Further, the above-mentioned modified multi-component includes water-based fatty amine and water-based polyamide, and the weight ratio of water-based fatty amine and polyamide is 15:1-10:1. In this embodiment, specifically, the above-mentioned modified multi-component includes 25 parts of water-based fatty ami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com