A method for forming a packaging pattern

A pattern and integrated circuit technology, which is applied in the field of packaging pattern formation, can solve the problems of low adhesion between the molecules in the lower layer of the packaging pattern and the substrate molecules, and the high viscosity of the packaging pattern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the present invention, there is no special limitation on the preparation method of the above-mentioned substrate. It is preferably a composite substrate made of Si, and the thickness of the substrate is preferably 100-1000 um, more preferably 200-800 um, and most preferably 725 um.

[0040] The step b) specifically includes: spin-coating an organic photoresist solution on the substrate at a speed of 5-45 r / s, and baking at 90-150° C. for 2-8 minutes to obtain a photoresist film. The spin coating speed is preferably 25-45 r / s, more preferably 35 r / s. The above-mentioned baking temperature is preferably 90 to 120°C, more preferably 105°C. The above baking time is preferably 2.5 to 6 minutes, more preferably 3 to 4 minutes. The organic solution of the photoresist preferably has a propylene resin concentration of 20%-30%, a multifunctional acrylate (or fat) concentration of 10%-20%, and a photosensitizer content of 5%-15%. The thickness of the photoresist film obtained...

Embodiment 1

[0046] a) The Si substrate substrate is cleaned with deionized water for 2 minutes, blown dry with nitrogen gas, and dried in an oven.

[0047] b) Spin-coat THB121N photoresist (photosensitizer content 5%-15%) of JSR Company on the substrate at a speed of 35r / s, and bake the glue on a hot stage at 105°C for 200 seconds to obtain a 20 micron photoresist. photoresist film;

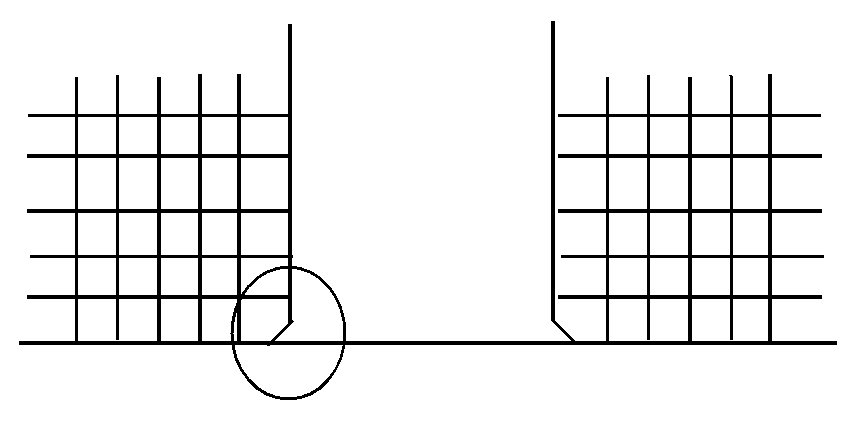

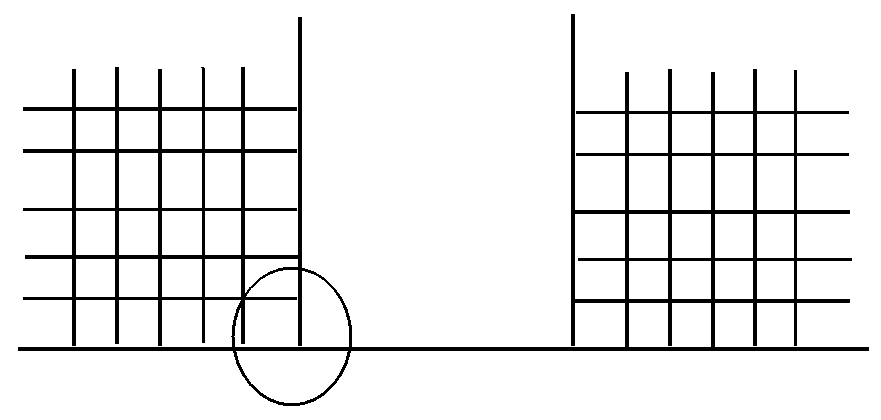

[0048] c) Exposure of the photoresist film to an exposure energy of 300mj / cm 2 Expose to ultraviolet light for 90 seconds, develop at 23°C for 90 seconds, wash with water, spin dry, and expose to obtain multiple cuboid-shaped preforms;

[0049] d) Bake the multiple preforms obtained in step c) at 150°C for 110 seconds;

[0050] e) The product obtained in step d) is subjected to an exposure energy of 660mj / cm 2 The ultraviolet light was exposed for 60 seconds, and then baked at 140° C. for 25 minutes, and the baked product was bombarded with oxygen plasma for 1 minute.

Embodiment 2

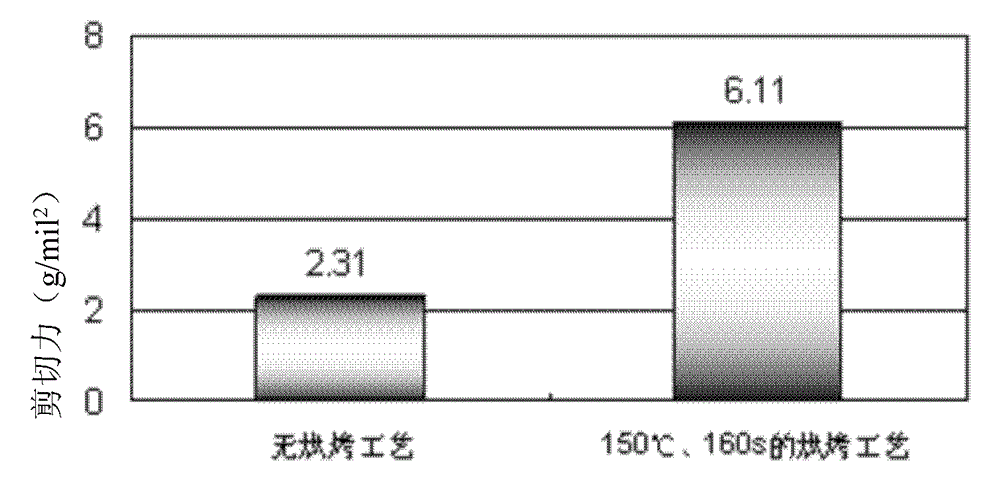

[0052] The baking time is 160 seconds in step d), and all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com