Toner for electrostatic image development

An electrostatic charge image and toner technology, applied in the direction of developer, electrography, optics, etc., can solve the problems of difficult toner particles, high chargeability, and inability to ensure image quality, and achieve excellent chargeability, low temperature The effect of excellent fixability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0136] Concretely showing a production example of a toner containing a colorant when the toner of the present invention is produced by the emulsion polymerization coagulation method, it consists of the following steps:

[0137] (1-1) A shell resin particle dispersion liquid preparation process of forming shell resin particles made of a shell resin in an aqueous medium to prepare a dispersion liquid in which the shell resin particles are dispersed;

[0138] (1-2) A binder resin polymerization process in which binder resin particles made of binder resin are formed by polymerization in an aqueous medium to prepare a dispersion liquid in which the binder resin particles are dispersed;

[0139] (1-3) A coloring agent particle dispersion liquid preparation process of preparing a dispersion liquid obtained by dispersing colorant particles made of a colorant in an aqueous medium;

[0140] (2) a nuclei particle forming process of agglomerating the binder resin microparticles and the co...

manufacture example 1

[0234] (1) Preparation process of binder resin particle dispersion

[0235] (1-1) Step 1 Aggregation

[0236] Add an anionic surfactant solution obtained by dissolving 2.0 parts by mass of anionic surfactant "sodium lauryl sulfate" in 2900 parts by mass of ion-exchanged water in advance into a device equipped with a stirring device, a temperature sensor, a temperature control device, and a cooling In the reaction container of the tube and the nitrogen introduction device, the internal temperature was raised to 80° C. while stirring at a stirring rate of 230 rpm under a nitrogen flow.

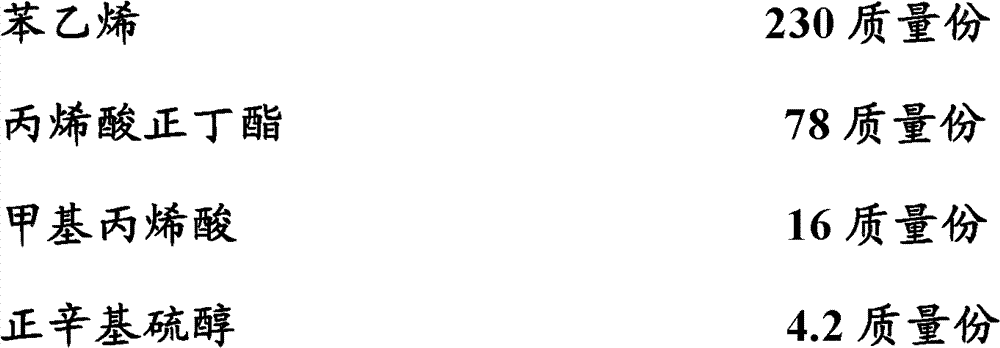

[0237] 9.0 parts by mass of a polymerization initiator "potassium persulfate (KPS)" was added to the anionic surfactant solution, and after the internal temperature was 78° C., the

[0238]

[0239] Formed monomer solution [1]. After completion of the dropwise addition, polymerization was carried out by heating and stirring at 78° C. for 1 hour (first-stage polymerization), thereby preparin...

manufacture example 1~16

[0275] (1) Production of carrier

[0276] Add the copolymer resin particles of the ferrite nucleus of 100 mass parts and the cyclohexyl methacrylate / methyl methacrylate (copolymerization ratio 5 / 5) of 5 mass parts in the high-speed mixer with paddle, at 120 The mixture was stirred and mixed for 30 minutes at °C, and a resin coating was formed on the surface of the ferrite core under the action of a mechanical impact force, thereby obtaining a carrier with a volume-based median diameter of 50 μm.

[0277] The volume-based median diameter of the carrier was measured using a laser diffraction particle size distribution analyzer "HELOS" (manufactured by Sympathique) equipped with a wet disperser.

[0278] (2) Mixing of toner and carrier

[0279] The above-mentioned carrier was added to each toner [1] to [16] to a toner concentration of 6%, and mixed for 30 minutes at a rotation speed of 45 rpm using a micro V-type mixer (Tsutsui Physical and Chemical Device Co., Ltd.). This made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com