Dual-voltage control switch reluctance motor and dual-voltage control drive device thereof

A technology of switched reluctance motors and reluctance motors, applied in the direction of single motor speed/torque control, sustainable manufacturing/processing, climate sustainability, etc., can solve unreliable stability, low switching frequency, and inability to obtain low Noise and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

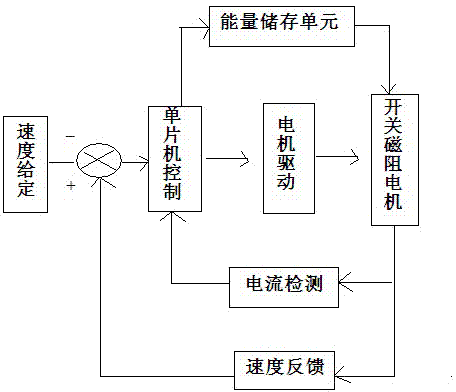

[0014] see figure 1 , the dual-voltage control switched reluctance motor, including a speed setting unit, a PID regulator, a single-chip control unit, a motor drive unit, a current detection unit, a speed feedback unit for detecting the speed of the switched reluctance motor, and the switched reluctance motor; The speed given unit, the single-chip microcomputer control unit, the motor drive unit and the switched reluctance motor are electrically connected in sequence; the current detection unit is connected between the switched reluctance motor and the single-chip microcomputer control unit, and the current detection unit detects the motor winding current of the switched reluctance motor And output the current signal to the microcontroller control unit; the speed feedback unit is connected between the switched reluctance motor and the PI regulator, the speed feedback unit detects the speed of the switched reluctance motor and feeds the speed signal back to the PI regulator; the...

Embodiment 2

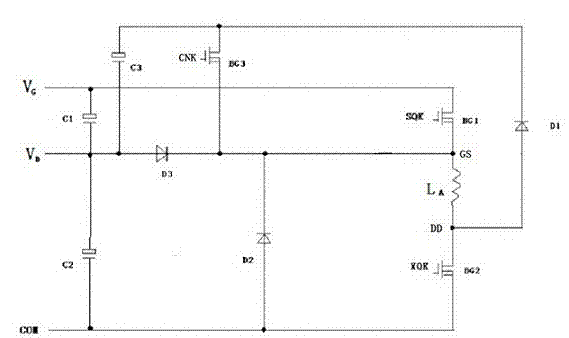

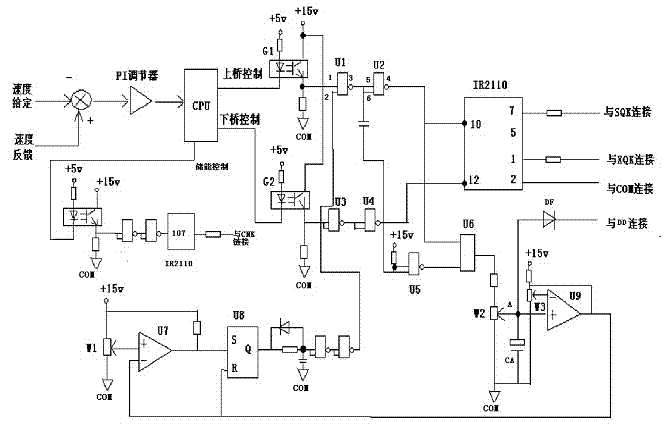

[0020] see figure 2 with image 3 , the dual-voltage control driving device of the switched reluctance motor, including the first MOS transistor BG1, the third diode D3 and a single-chip microcomputer control unit for controlling the first MOS transistor BG1 to be turned on and off; the first MOS transistor BG1 The source is connected to the positive power supply terminal of the switched reluctance motor, the drain is used to connect to the first power supply VG, the gate is connected to the single-chip control unit; the cathode of the third diode D3 is connected to the positive power supply terminal of the switched reluctance motor, and the anode Used to connect the second power supply VD. Also includes an energy storage unit, the energy storage unit includes a third MOS transistor BG3, a first capacitor C1, a second capacitor C2, a third capacitor C3, a first diode D1 and a second diode D2; the first capacitor C1 is connected between the drain and source of the MOS tube; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com