Long-acting slow-release microcapsule food antistaling agent and preparation method thereof

A microcapsule and slow-release technology, which is applied in the field of long-acting slow-release microcapsule food preservatives and their preparation, can solve the problems of large amount of synthetic preservatives, achieve high drug loading, prolong action time, and be easy to industrialize The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

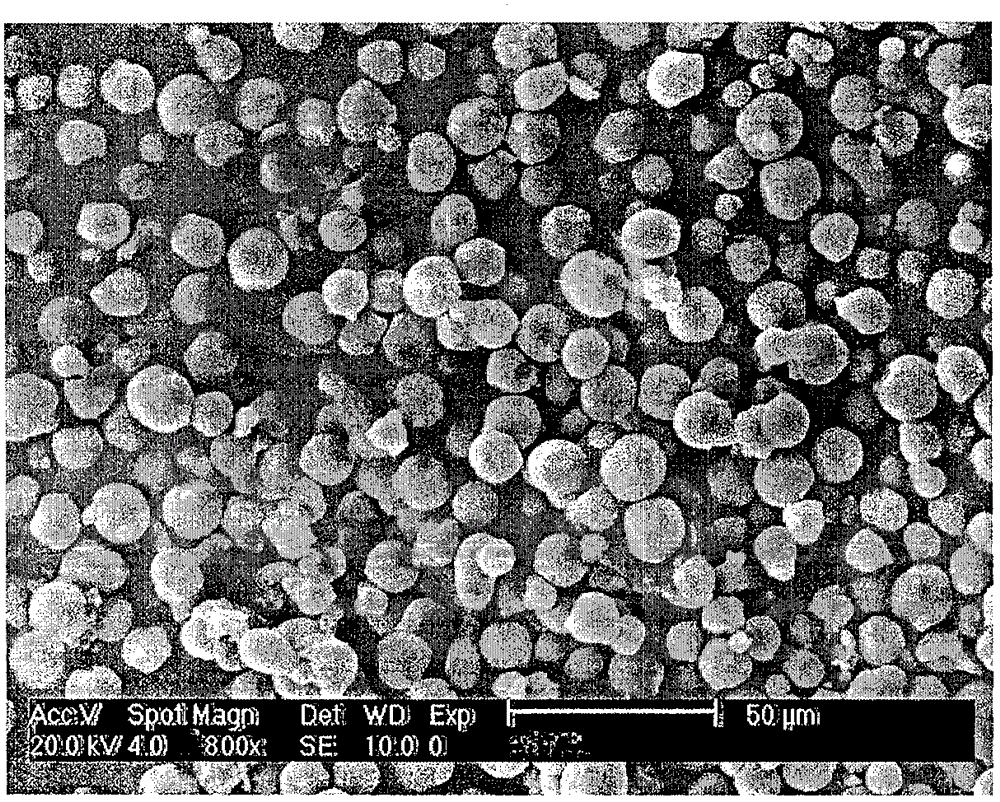

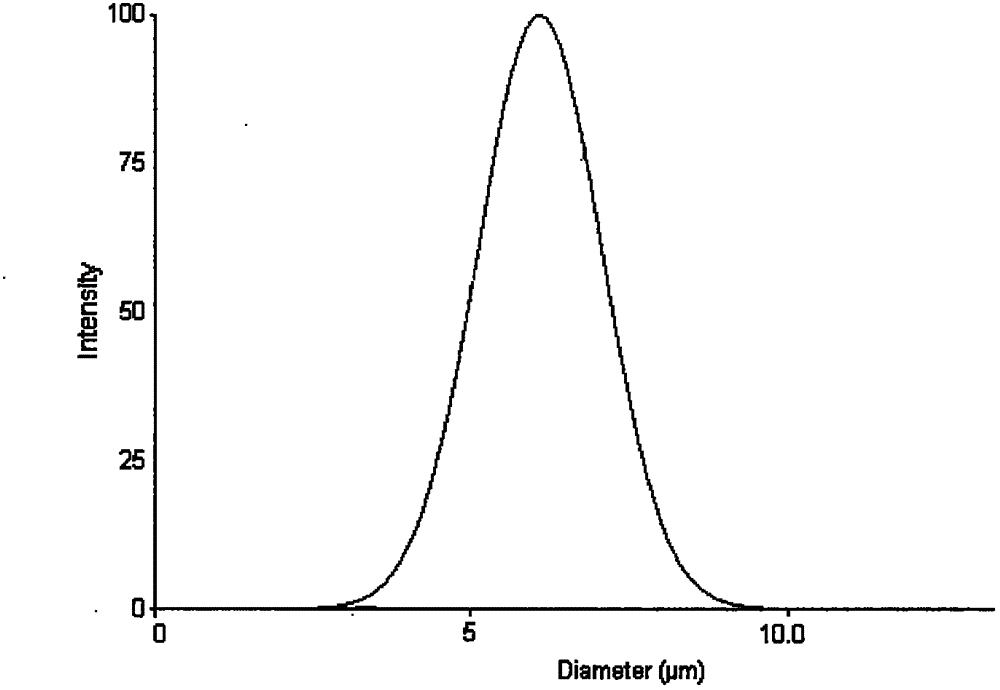

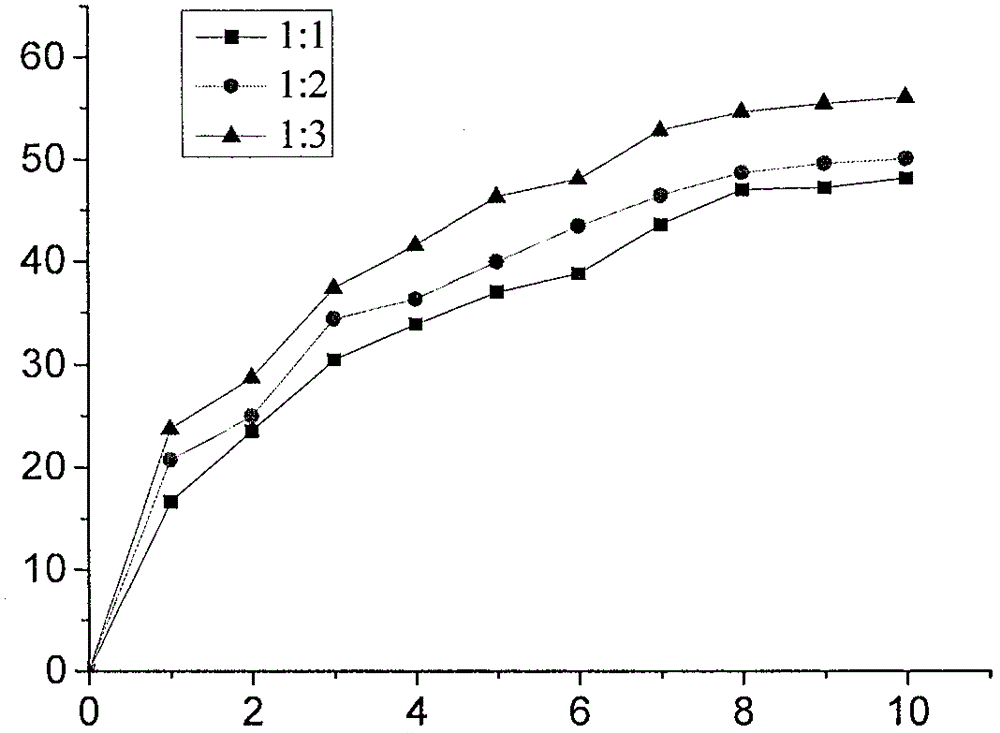

Image

Examples

Embodiment 1

[0032] (1) 0.5 gram of deacetylation degree is 80%, and the chitosan that weight-average molecular weight is 200,000 is dissolved in the acetic acid solution that mass fraction is 1.0% to be made into the chitosan-acetic acid solution that mass fraction is 0.5% in 99.5 gram mass fraction; Dissolving 1.0 gram of B-type gelatin in 99.0 gram of distilled water to make a gelatin solution with a mass fraction of 1.0%, and adjusting its pH value to 3.5 with a 10% acetic acid solution with a mass fraction;

[0033] (2) The chitosan acetic acid solution and the gelatin solution made into (1) are mixed uniformly, add 1.5 gram of patchouli oil and 2.0 g of emulsifier sorbitan sesquioleate, stir under the stirring speed of 2000r / min Emulsified for 20min to make patchouli oil emulsion;

[0034] (3) Reduce the stirring speed of (2) to 400r / min, then, adjust the pH value of the system to 5.0 with 10% sodium hydroxide solution, stir and react in a water bath at 50°C for 20min; remove the wat...

Embodiment 2

[0036] (1) be 90% with 0.5 gram deacetylation degree, the chitosan that weight-average molecular weight is 300,000 is dissolved in the acetic acid solution that mass fraction is 1.0% to be made into the chitosan acetic acid solution that mass fraction is 0.5% in 99.5 gram mass fraction; Dissolving 2.0 grams of B-type gelatin in 98.0 grams of distilled water to form a gelatin solution with a mass fraction of 2.0%, and adjusting its pH value to 4.0 with a mass fraction of 10% acetic acid solution;

[0037] (2) the chitosan acetic acid solution and the gelatin solution made into (1) are mixed uniformly, add 5.0 gram of patchouli oil and 4.0 gram of emulsifier sorbitan sesquioleate, stir under the stirring speed of 6000r / min Emulsify for 10min to make patchouli oil emulsion;

[0038] (3) Reduce the stirring speed of (2) to 500r / min, then, adjust the pH value of the system to 5.5 with 10% sodium hydroxide solution, stir and react in a water bath at 50°C for 30min; remove the water ...

Embodiment 3

[0040] (1) 1.0 gram of deacetylation degree is 96%, and the chitosan whose weight-average molecular weight is 500,000 is dissolved in 99.0 grams of mass fraction and is made into the chitosan-acetic acid solution that mass fraction is 1.0% in the acetic acid solution of 1.0%; Dissolving 3.0 grams of B-type gelatin in 97.0 grams of distilled water to make a gelatin solution with a mass fraction of 3.0%, and adjusting its pH value to 4.0 with a 10% acetic acid solution with a mass fraction;

[0041] (2) the chitosan acetic acid solution and the gelatin solution made into (1) are mixed evenly, add 8.0 gram of patchouli oil and 6.0 gram of emulsifier sorbitan sesquioleate, stir under the stirring speed of 8000r / min Emulsified for 15min to make patchouli oil emulsion;

[0042] (3) Reduce the stirring speed of (2) to 600r / min, then, adjust the pH value of the system to 5.0 with 10% sodium hydroxide solution, stir and react in a water bath at 50°C for 30min; remove the water bath, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com