Environment-friendly aggregate with gas-liquid pollutant purifying function and preparation technology thereof

A preparation process and technology for pollutants, applied in the field of environment-friendly aggregate and its preparation process, can solve the problems of limited types of pollutants, difficult to maintain long-term activity, secondary pollution, etc., achieve obvious sound absorption effect, and improve photocatalysis. Efficiency, the effect of enhancing the purification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

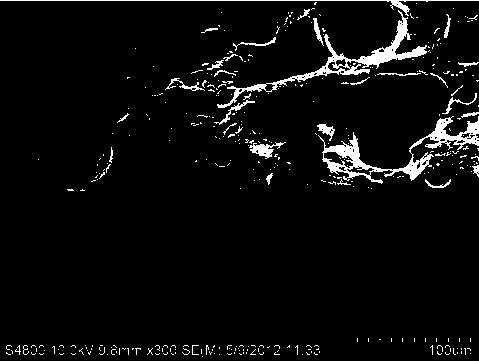

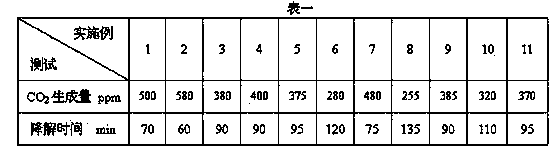

[0038] Select grade 300 porous shale ceramsite (that is, aggregate), put it in an ultrasonic cleaner for ultrasonic cleaning (the power of the ultrasonic cleaner is 300W, and the cleaning time is 50 minutes), take it out after cleaning, and dry it at 105°C to obtain The ceramsite after cleaning; Weigh sodium hydroxide, dissolve in water, the preparation concentration is 10 -1 mol / L sodium hydroxide solution; weigh Degussa P25 (that is, the photocatalytic material is active TiO 2 ) into the sodium hydroxide solution prepared above, so that the concentration of Degussa P25 is 1g / L, ultrasonically disperse for half an hour to make it evenly dispersed, and obtain mixture A; take the cleaned ceramsite and place it in a vacuum water-saturated machine, pump Vacuum (vacuum degree is -0.094MPa), then inject mixture A, the amount of mixture A is subject to immersion ceramsite, vacuum negative pressure soak ceramsite for 24h; take out ceramsite, dry at 105°C for 6h, and then calcined at ...

Embodiment 2

[0041] Select 500-grade porous fly ash ceramsite (that is, aggregate), put it in an ultrasonic cleaner for ultrasonic cleaning (the power of the ultrasonic cleaner is 300W, and the cleaning time is 40 minutes), take it out after cleaning, and dry it at 105°C. Get the cleaned ceramsite; prepare an ammonia solution with a pH value of 10; weigh ZnO (that is, the photocatalytic material) and put it into the ammonia solution prepared above, so that the concentration of ZnO is 2g / L, and ultrasonically disperse it for half an hour to make it uniform Disperse, this mixture is named B; take the cleaned ceramsite and place it in a vacuum water saturation machine, vacuumize (vacuum degree is -0.098MPa), and then inject B, the amount of B is based on the ceramsite submerged, and the vacuum negative pressure Soak the ceramsite for 24 hours; take out the ceramsite, dry it at 105°C for 3h, and then calcinate it at 300°C for 3h (the heating rate is 5°C / min). Environmentally friendly ceramsite...

Embodiment 3

[0044] Select 700-grade porous clay ceramsite (that is, aggregate), put it in an ultrasonic cleaner for ultrasonic cleaning (the power of the ultrasonic cleaner is 300W, and the cleaning time is 30 minutes), take it out after cleaning, and dry it at 105°C to obtain a clean The final ceramsite; Weigh potassium hydroxide, dissolve it in water, and prepare a concentration of 10-4 mol / L potassium hydroxide solution; weigh WO 3 (that is, the photocatalytic material) is placed in the potassium hydroxide solution prepared above, so that the WO 3 The concentration is 5g / L, ultrasonically dispersed for half an hour to make it evenly dispersed, and this mixture is named C; take the cleaned ceramsite and place it in a vacuum water saturator, vacuumize (vacuum degree is -0.096MPa), and then inject C , the amount of C is subject to immersion ceramsite, vacuum negative pressure soak ceramsite for 24h; take out ceramsite, dry at 105°C for 4h, and then calcined at 450°C for 2h (heating rate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com