Salt resistant biochemical functional type flocculating agent used for oil field waste water and preparation method thereof

A functional technology for oilfield wastewater, applied in the chemical field, can solve the problems of poor salt tolerance and secondary pollution of flocculants, and achieve the effects of easy control of the reaction, mild reaction conditions, and reduced secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

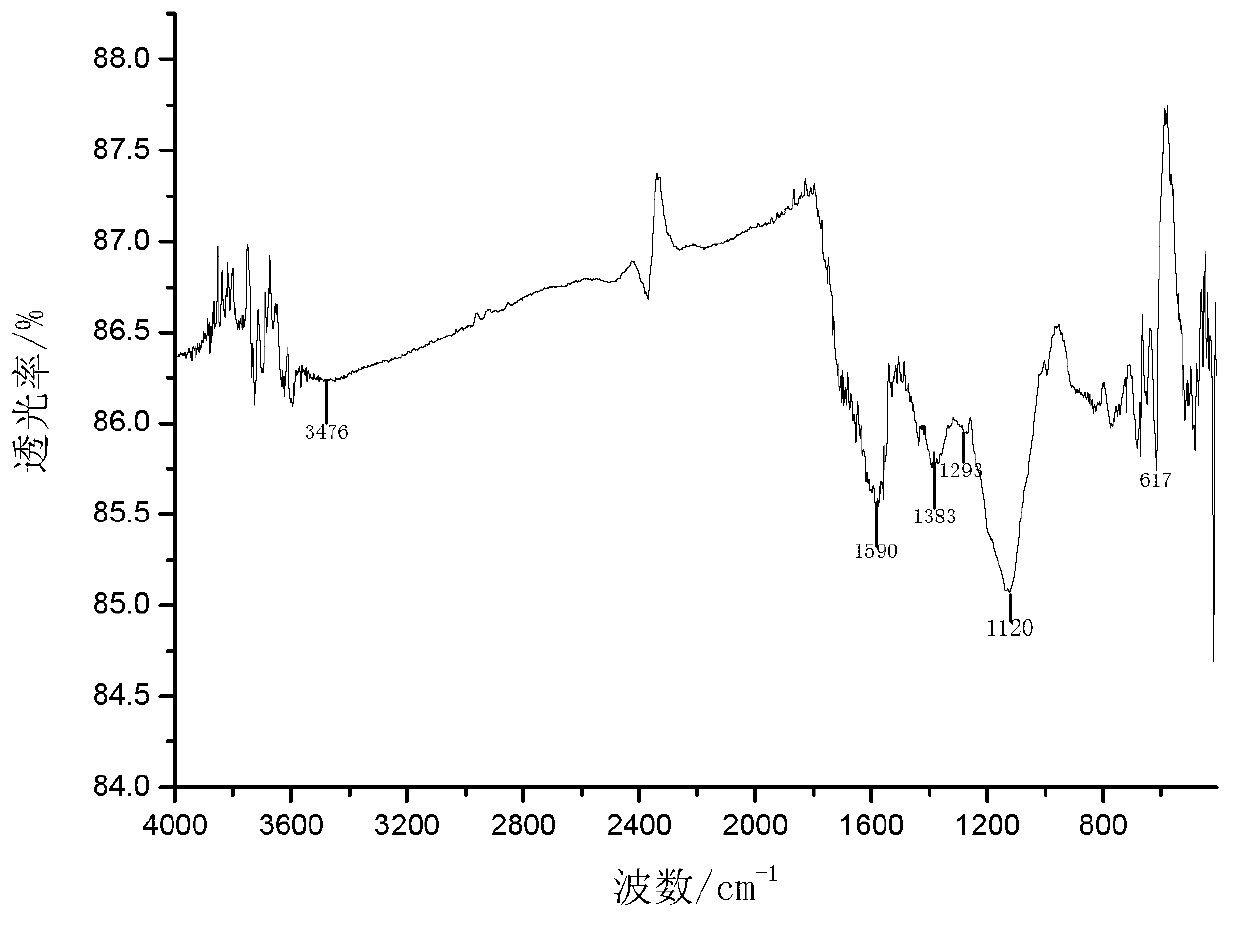

Method used

Image

Examples

Embodiment 1

[0020] (1) The formulation of a salt-tolerant biochemical functional flocculant for oilfield wastewater of the present invention is: 1.5g humic acid, 2g initiator solution, and 100g acrylamide.

[0021] (2) The preparation method of a salt-tolerant biochemical functional flocculant for oilfield wastewater of the present invention is as follows:

[0022] (1) Put humic acid into a beaker, dissolve it with a sodium hydroxide solution with a concentration of 0.01mol / L, and obtain a sodium humate solution with a mass percentage concentration of 20% for later use;

[0023] (2) Put 100g of acrylamide into the reactor, add distilled water and stir until completely dissolved, add 2g of initiator solution according to the proportion, stir evenly, and adjust the pH value of the solution to 6;

[0024] (3) Heat in a water bath at 35°C until the solution becomes viscous and cannot be stirred, stop stirring, react at 35°C for 12 hours, take out the obtained product, dry to constant weight, ...

Embodiment 2

[0033] The proportion of a salt-tolerant biochemical functional flocculant for oilfield wastewater provided in Example 2 and the reaction time of the preparation method are shown in Table 2, and the rest are the same as in Example 1.

[0034] The oilfield wastewater samples were taken, and the COD index was measured according to "GB / T 11914-89 Determination of Chemical Oxygen Demand in Water Quality by Dichromate Method". According to the flocculation experimental method introduced in "Water Supply Treatment" and "Water Treatment Engineering Theory and Application", the coagulation-assisted settlement test for simulating water purification production is carried out. Determine the optimal dosage of medicine. After adding the medicament, measure the COD index again and calculate the COD removal amount.

[0035] The molecular weight and COD removal rate are shown in Table 2.

[0036] Table 2 Reaction conditions and results of a salt-tolerant biochemical functional flocculant fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com