Preparation method of piezoelectric ceramics-polymer composite material

A technology of piezoelectric ceramics and composite materials, which is applied in the field of acoustic materials, can solve the problems of difficult preparation of large-area 2-2 or 1-3 composite materials and ceramic substrates for acoustic transducers, and achieve high reliability, Ease of operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

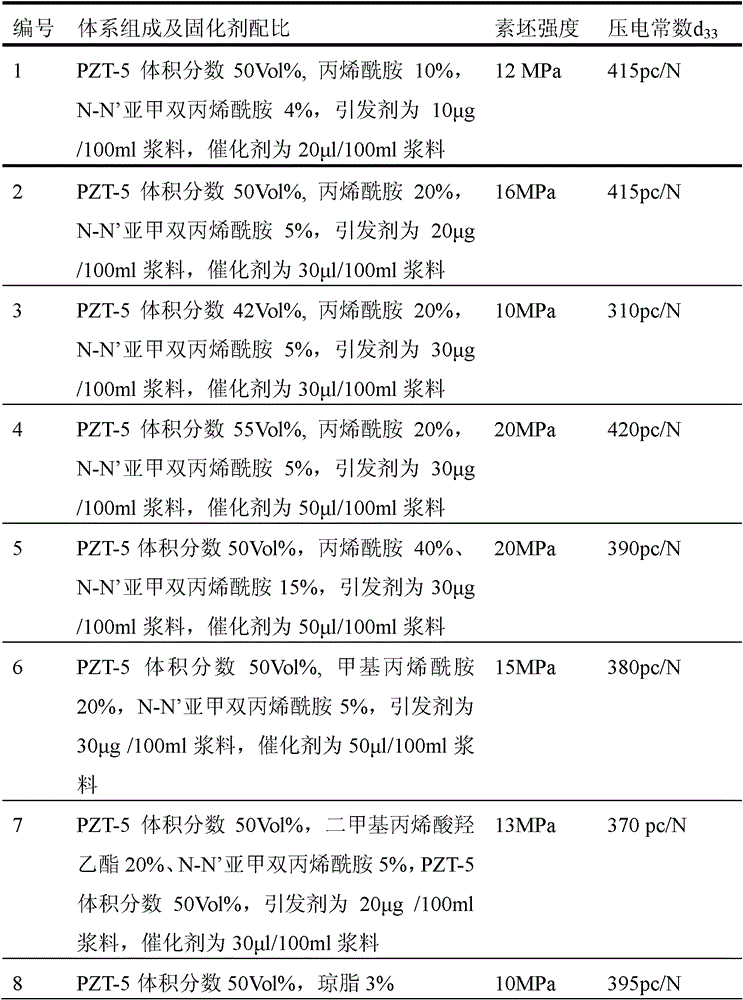

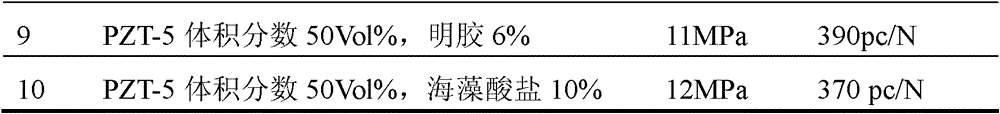

Examples

Embodiment 1

[0031] Mix 6g of acrylamide (AM), 2g of N,N'-methylenebisacrylamide (MBAM), 350g of lead zirconate titanate powder and 2g of dispersant sodium polyacrylate with 50g of deionized water to obtain a high solid phase For low-viscosity ceramic slurry, after vacuuming and defoaming, add 1.5μg initiator and 15μl catalyst, stir evenly, pour it into a circular mold with a diameter of 11cm, and place it in an oven at 60°C for 10 hours. After the ceramic slurry is cured The mold was demoulded to obtain a ceramic green body with a strength greater than 10 MPa. Two column arrays with a side length of 800 μm were cut vertically and horizontally on the green body, and then sintered at 1260° C. for 3 hours. After cooling, the sintered body is filled with epoxy resin, cured at room temperature for 48 hours, and the base is cut off to obtain a 1-3 piezoelectric composite material.

Embodiment 2

[0033] Mix 15g of acrylamide (AM), 5g of N,N'-methylenebisacrylamide (MBAM), 200g of lead zirconate titanate powder and 2g of dispersant sodium polyacrylate with 30g of deionized water to obtain a high solid phase For low-viscosity ceramic slurry, after vacuuming and defoaming, add 1.5μg initiator and 20μl catalyst, stir evenly, pour it into a circular mold with a diameter of 9cm, and place it in an oven at 60°C for 10 hours. After the ceramic slurry is cured Remove the mold to obtain a ceramic green body with a strength greater than 10 MPa, cut a row of 700 μm parallel grooves on the green body, and then heat-preserve and sinter at 1260° C. for 3 hours. The sintered body is filled with epoxy resin, and the base is cut off to obtain a 2-2 piezoelectric composite material.

Embodiment 3

[0035] Add 1.5g of gelatin to 25g of deionized water, heat to 40°C and stir. After the gelatin is completely dissolved, add 170g of niobium magnesium zirconate lead ceramic powder and 2g of dispersant sodium polyacrylate, continue stirring evenly, and then mix and ball mill to obtain high-solids The relatively low-viscosity ceramic slurry, after vacuum defoaming, is poured into a circular mold with a diameter of 8 cm, and left at room temperature for one day, and the ceramic slurry is solidified and demolded to obtain a ceramic green body with a strength greater than 10 MPa, which is cut into A row of grooves of 500 μm parallel to each other, followed by sintering at 1200° C. for 4 hours. The sintered body is filled with polyurethane, and the base is cut off to obtain a 2-2 piezoelectric composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com