Thermotropic super hydrophilic resin and preparation method thereof

A super-hydrophilic and resin technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of difficult to meet the requirements of mechanical properties and corrosion resistance, poor flexibility of the coating film, penetration corrosion, etc., to achieve good corrosion resistance and Physical and mechanical properties, excellent anti-corrosion performance, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

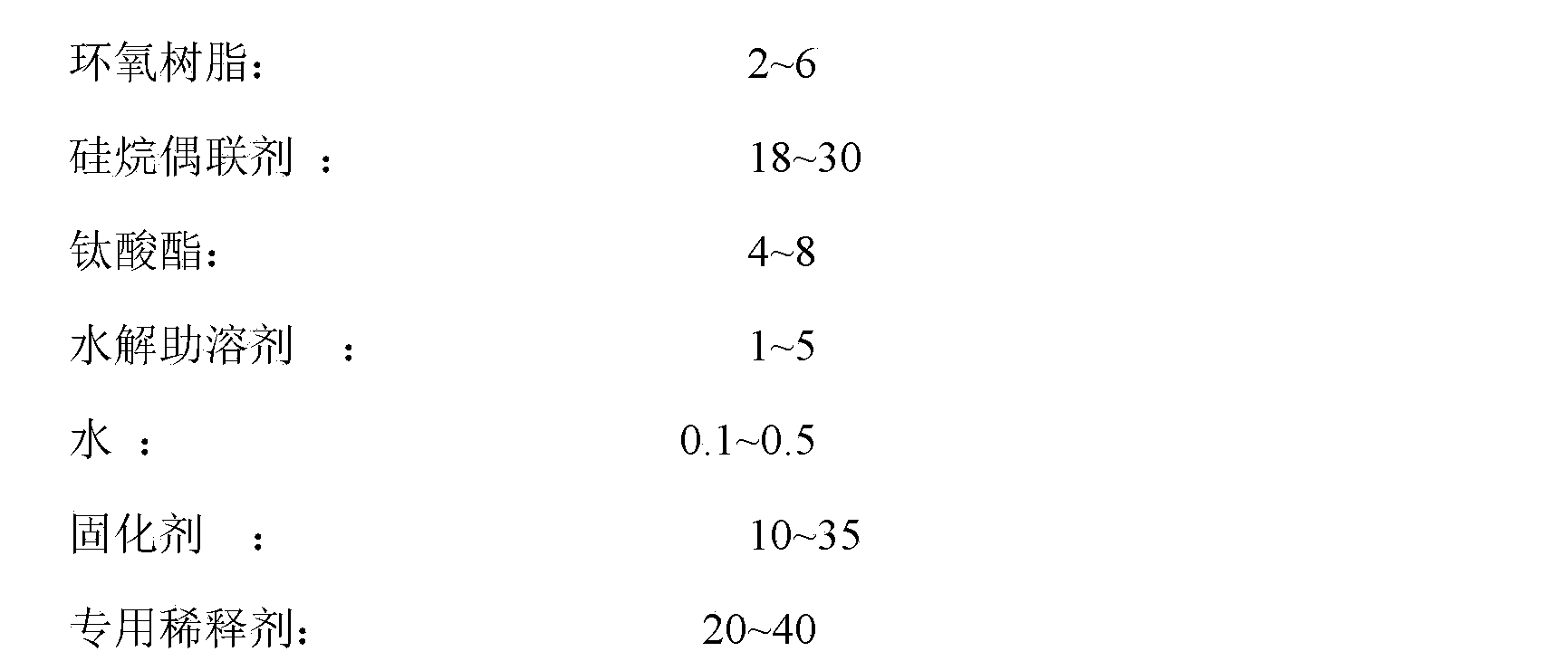

[0026] (1) In a four-necked glass flask equipped with a stirrer, reflux condenser, dropping funnel, and thermometer, add 100gKH-560 dropwise to 10g ethanol-0.05g water mixture, hydrolyze at room temperature for 2 hours, and distill under reduced pressure to remove the ethanol .

[0027] (2) Heat and melt 20g epoxy resin E-20 in a four-necked glass flask equipped with a stirrer, reflux condenser and thermometer, put in 26g tetra-n-butyl titanate, and continue heating to 170-180°C for one hour Then, the hydrolyzed solution prepared in step 1 was added, and after keeping the temperature at 170 to 180° C. for 2 hours, 50 g of xylene and 50 g of ethyl acetate were added after cooling. Package A component of heat-induced super-hydrophilic resin.

[0028] (3) Polyamide curing agent is separately packaged as component B.

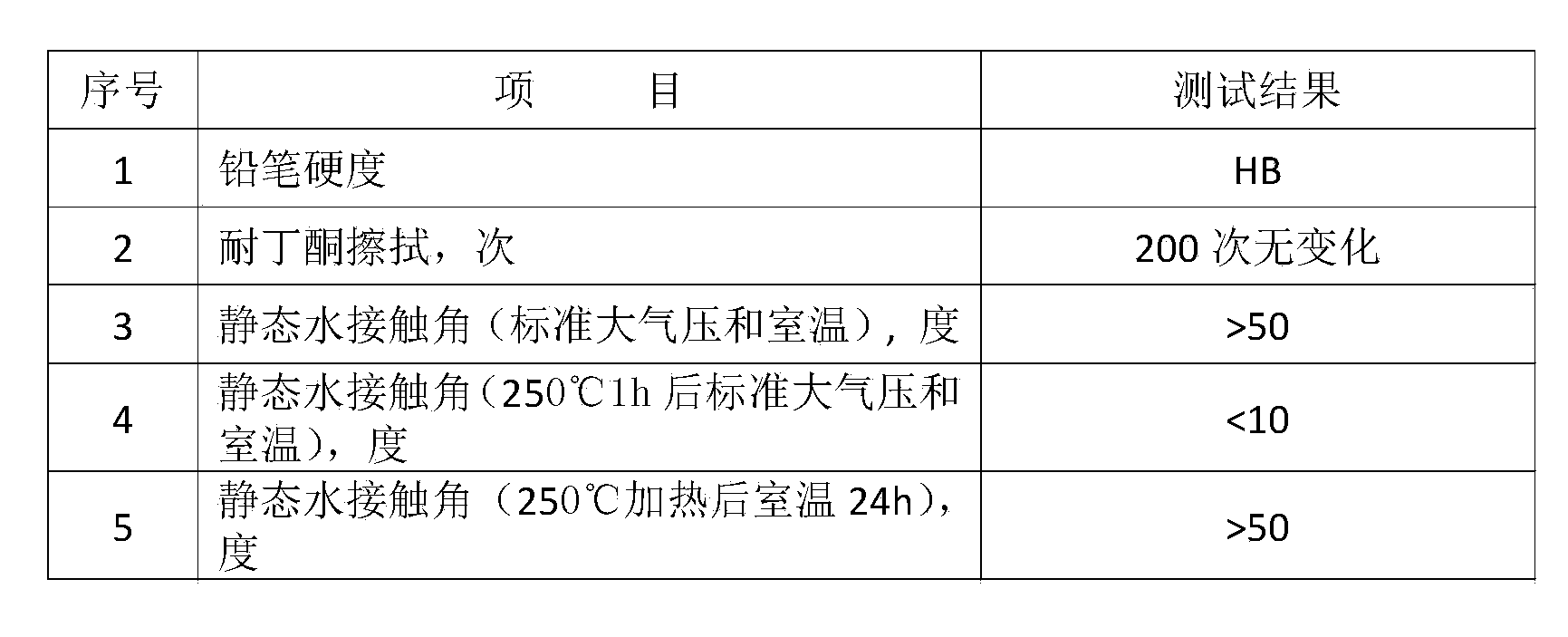

[0029] According to component A: component B=2:1 ratio, paint and spray the sample board, and the test performance is as follows after 7 days of drying at room temperatu...

Embodiment 2

[0032] (1) In a four-necked glass flask equipped with a stirrer, reflux condenser, dropping funnel, and thermometer, add 100gKH-560 dropwise to 10g ethanol-0.05g water mixture, hydrolyze at room temperature for 2 hours, and distill under reduced pressure to remove the ethanol .

[0033] (2) Heat and melt 12g epoxy resin E-12 in a four-necked glass flask equipped with a stirrer, reflux condenser and thermometer, put in 26g tetra-n-butyl titanate, and continue heating to 170 to 180°C for one hour Then, the hydrolyzed solution prepared in step 1 was added, and after keeping the temperature at 170 to 180° C. for 2 hours, 50 g of xylene and 50 g of ethyl acetate were added after cooling. Package A component of heat-induced super-hydrophilic resin.

[0034] (3) Polyamide curing agent is separately packaged as component B.

[0035] According to component A: component B=2:1 ratio, paint and spray the sample board, and the test performance is as follows after 7 days of drying at room temper...

Embodiment 3

[0038] (1) In a four-necked glass flask equipped with a stirrer, reflux condenser, dropping funnel, and thermometer, add 100gKH-560 dropwise to 10g ethanol-0.05g water mixture, hydrolyze at room temperature for 2 hours, and distill under reduced pressure to remove the ethanol .

[0039] (2) Heat and melt 20g epoxy resin E-20 in a four-necked glass flask equipped with a stirrer, reflux condenser and thermometer, put in 26g tetraisopropyl titanate, and continue heating to 170 to 180°C for one hour Then, the hydrolyzate prepared in step 1 is added, and after keeping the temperature at 170 to 180° C. for 2 hours, 25 g of xylene, 25 g of cyclohexanone, and 50 g of ethyl acetate are added after cooling. Package A component of heat-induced super-hydrophilic resin.

[0040] (3) Polyamide curing agent is separately packaged as component B.

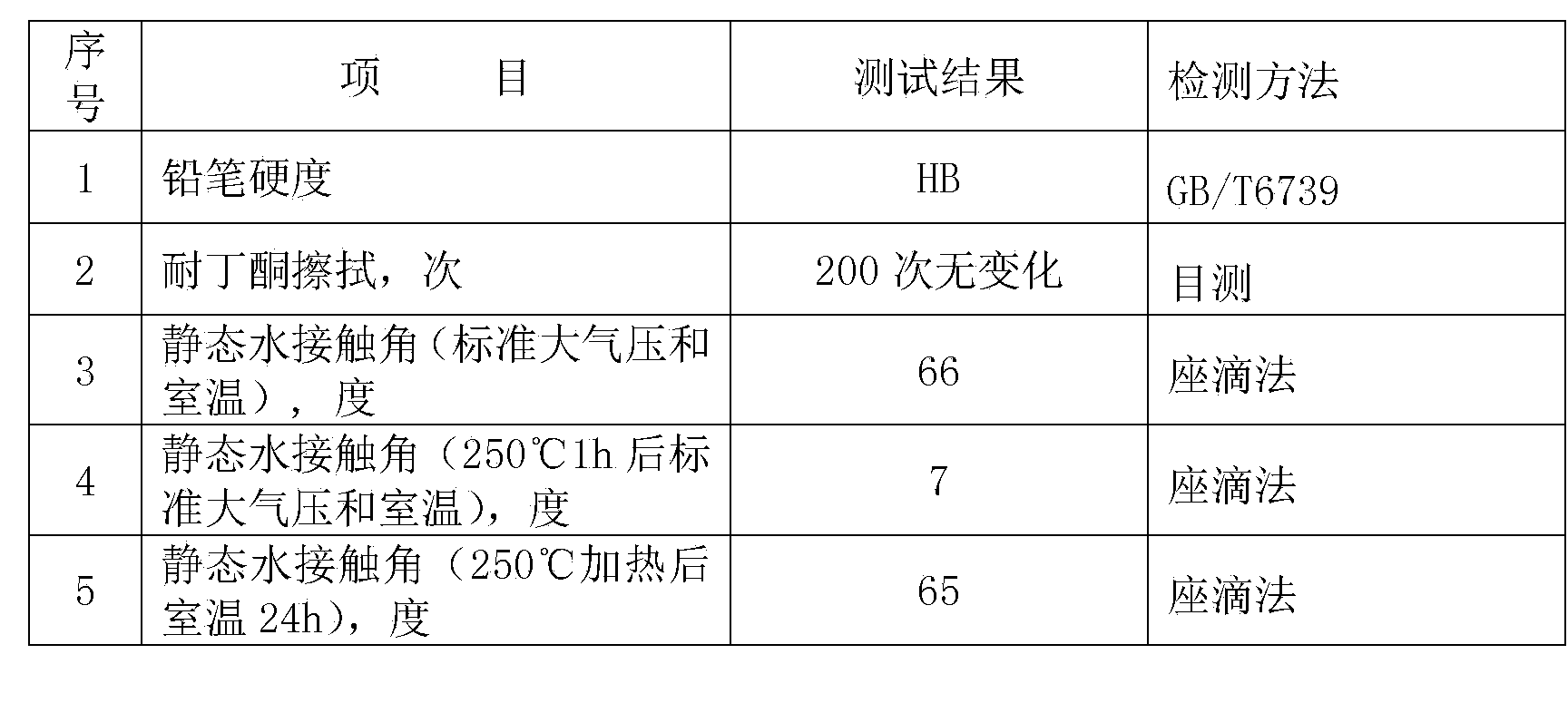

[0041] According to component A: component B=2:1 ratio, paint and spray the sample board, and the test performance is as follows after 7 days of drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com