Method for oxidizing isobutane

A technology of isobutane and oxidant, applied in chemical instruments and methods, preparation of oxidation reaction, preparation of peroxy compounds, etc., can solve the problems of greatly increased investment cost, huge oxidation equipment, long oxidation time, etc., and achieves low cost, high technology Simple, high isobutane conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Under the condition that the temperature is 60° C. and the pressure is 0.5 MPa, with the mixed gas of ozone and oxygen (wherein, 15 volume percent of the mixed gas is ozone) as the oxidant, isobutane, the mixed gas and solvent acetone are The oxidation reaction of isobutane is carried out under the condition that the molar ratio of butane: ozone in the mixed gas: solvent acetone is 1:1:1.

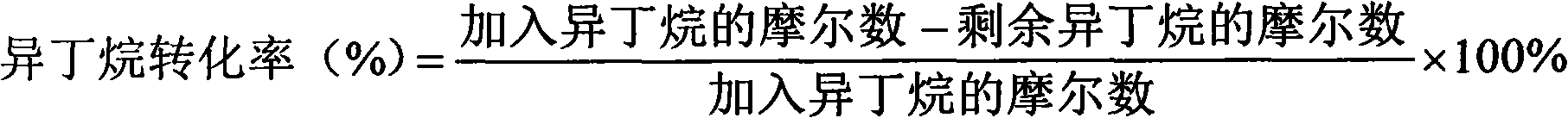

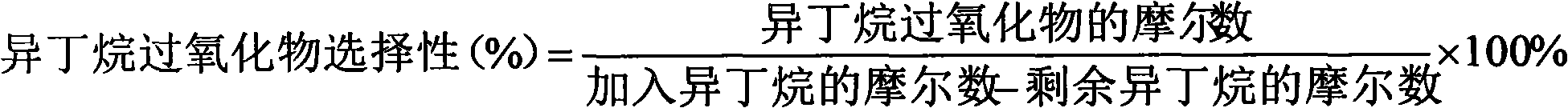

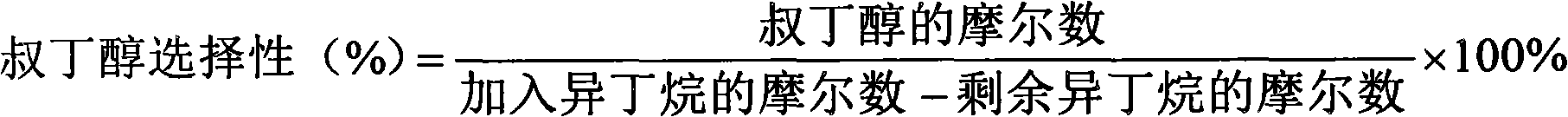

[0035] The results of the 2-hour reaction were as follows: the conversion rate of isobutane was 17%, the selectivity of isobutane peroxide was 94%, and the selectivity of tert-butanol was 6%.

Embodiment 2

[0037] The oxidizing agent used in this embodiment is a mixed gas containing ozone, which is prepared by using air as the oxygen source of the ozone generator (wherein, 15% by volume of the mixed gas is ozone), at a temperature of 20°C and Pressure is under the condition of 1.5MPa, isobutane, described mixed gas and solvent methanol are carried out isobutane according to the condition that isobutane: ozone in the described mixed gas: the molar ratio of solvent methanol is 1: 1: 5 oxidation reaction.

[0038] The result of reacting for 5 hours is as follows: the conversion rate of isobutane is 14%, the selectivity of isobutane peroxide is 97%, and the selectivity of tert-butanol is 3%.

Embodiment 3

[0040] Under the condition that the temperature is 80° C. and the pressure is 0.2 MPa, with the mixed gas of ozone and oxygen (wherein, 5 volume % of the mixed gas is ozone) as the oxidant, the isobutane, the mixed gas and the solvent acetonitrile are The oxidation reaction of isobutane is carried out under the condition that the molar ratio of butane: ozone in the mixed gas: solvent acetonitrile is 1:2:10.

[0041] The results of the 2-hour reaction were as follows: the conversion rate of isobutane was 21%, the selectivity of isobutane peroxide was 92%, and the selectivity of tert-butanol was 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com