Micro-electro-mechanical system (MEMS) strain type icing sensor and detection method

A technology of icing sensor and detection method, which is applied in the direction of microstructure technology, microstructure device, electromagnetic measurement device, etc., can solve the problems of complex manufacturing process, failure of imaging method, and reduction of measurement accuracy, and achieve high resolution and sensitivity, Reduce the effect of batch production and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

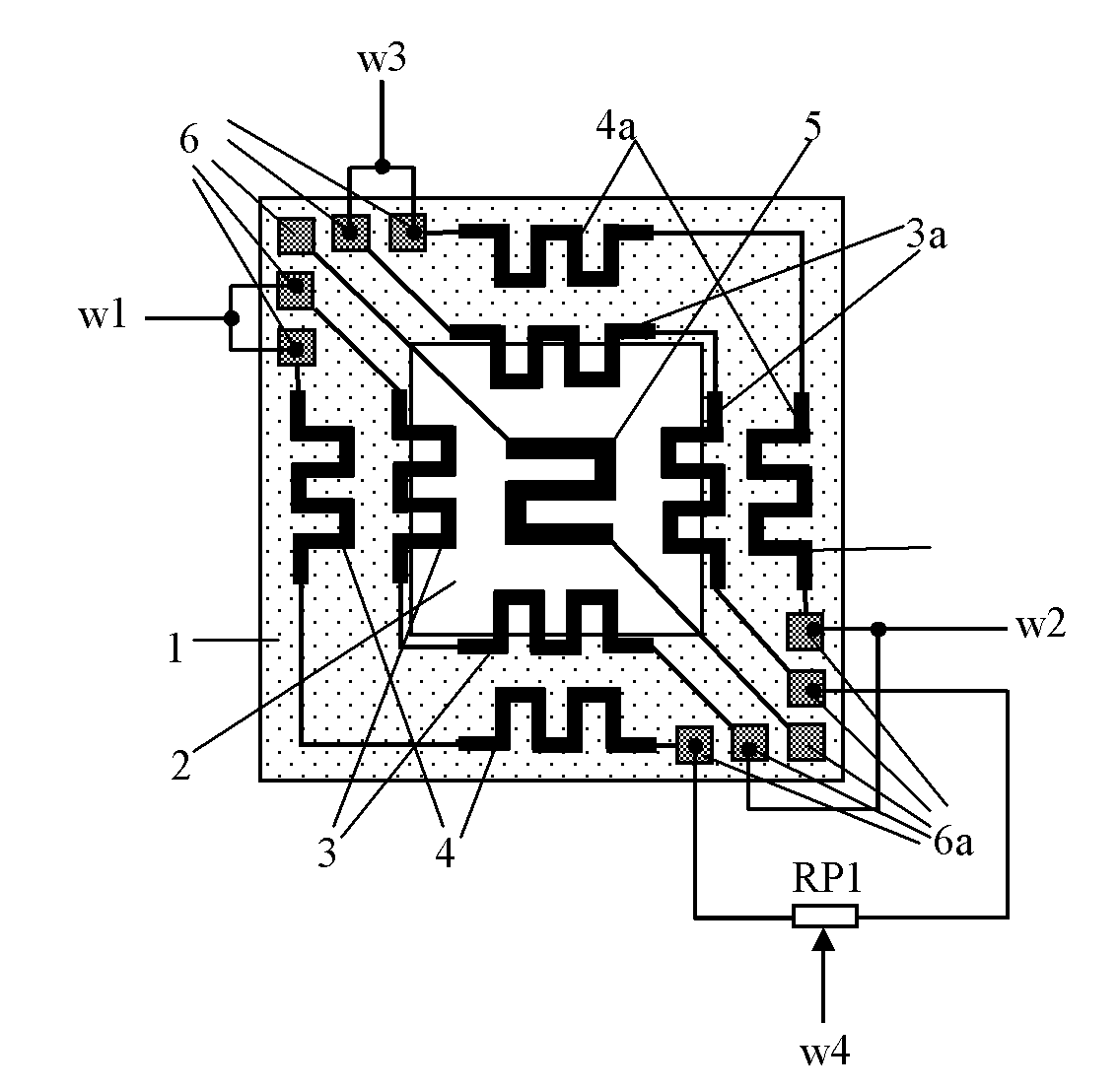

[0043] Example 1: Online monitoring of aircraft wing icing

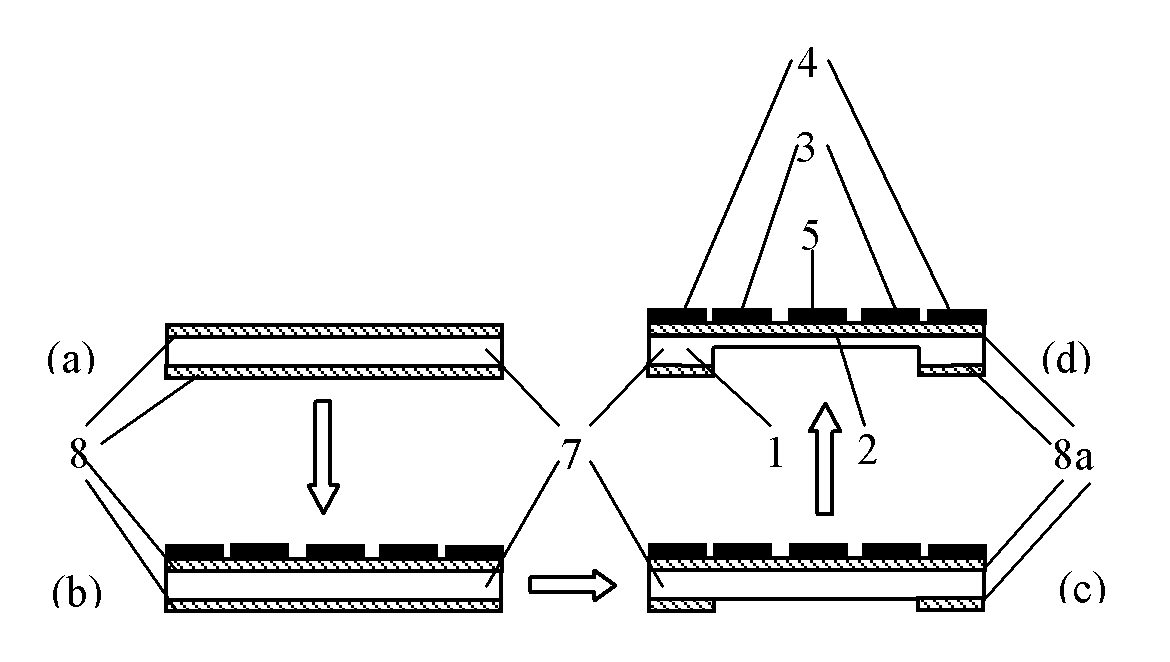

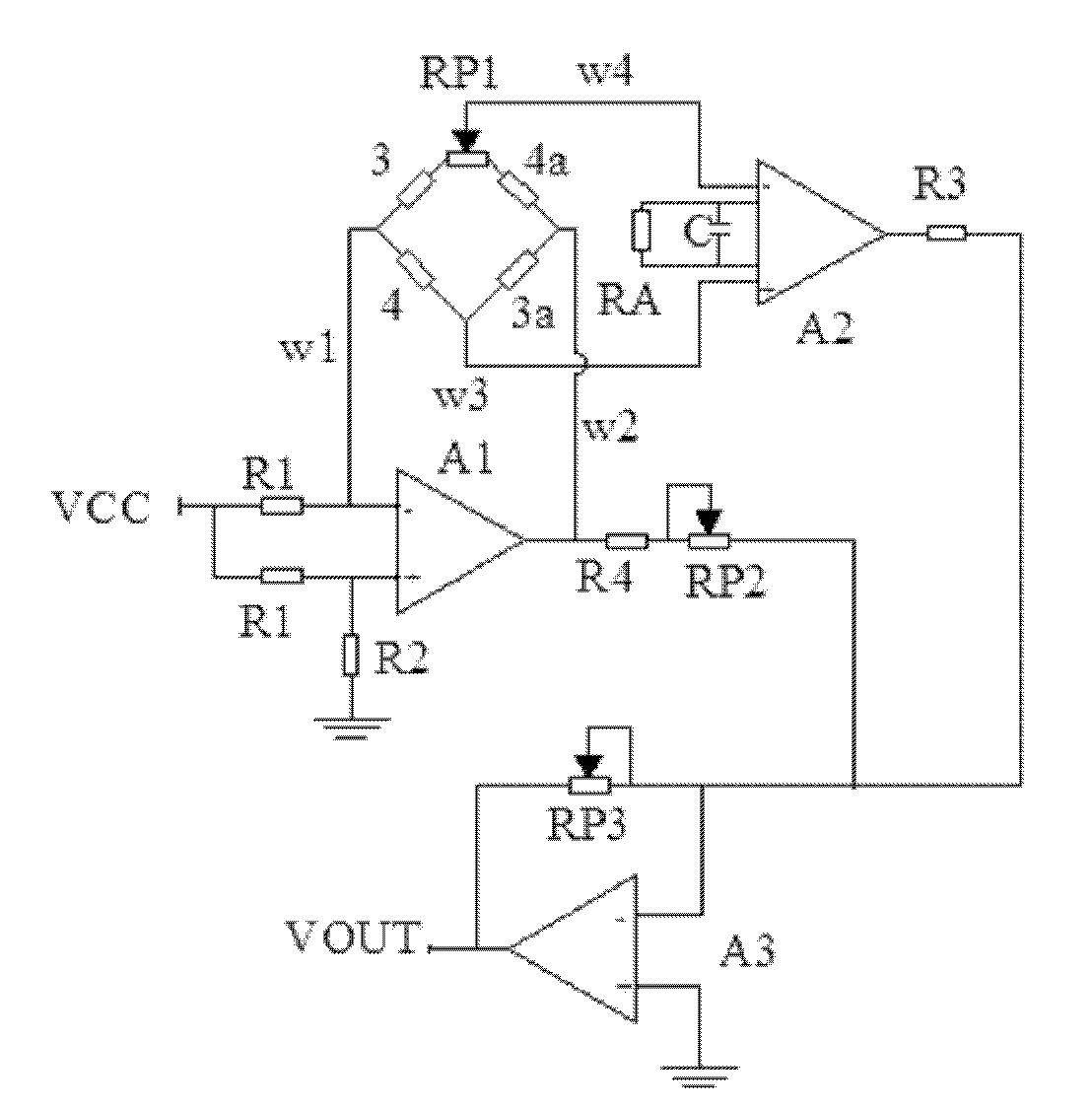

[0044] When the flat membrane 2 of the MEMS strain-type icing sensor in the present invention is not affected by the uniform force, the zero point balance of the bridge is adjusted through the potentiometer RP1. When the flat membrane 2 is deformed by the uniformly distributed pressure in the downward direction, stress distribution appears on the surface of the flat membrane 2. The maximum stress SMX on the upper surface is located at the position of the detection resistors 3 and 3a, which is a tensile stress, which causes the detection resistors 3 and 3a to be stretched along the length of the foil grid and the resistance value increases. When the temperature does not change, the resistance values of the reference resistors 4 and 4a do not change, so the bridge outputs a positive voltage value. When the temperature changes, the detection resistors 3 and 3a, and the reference resistors 4 and 4a have basically the sam...

Embodiment 2

[0045] Example 2: Daily icing data accumulation on transmission lines

[0046] Two types of icing sensors are required to detect the icing of transmission lines. The first type must have high resolution and sensitivity for detecting icing thickness, while the range does not need to be too large. It is used to monitor the icing thickness of the line when the icing is not serious. The long-term change of the icing thickness; the other type of detection range of ice thickness must be large enough, while the resolution and sensitivity do not need to be too high. The function is to cause severe icing disasters on transmission lines, and the icing thickness exceeds the range of the previous type of sensor It is used to judge whether a severe icing disaster occurs and its severity. The two types of icing sensors are used together to know the long-term loss of icing thickness before the occurrence of severe icing disasters. Combining the two types of icing sensors with monitoring device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com