Hydrogel dressing and preparation process thereof

A preparation process and hydrogel technology, which is applied in medical science, bandages, absorbent pads, etc., can solve the problems of single function and less hydrogel, and achieve the effects of good degradability, increased viscosity, and strong antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

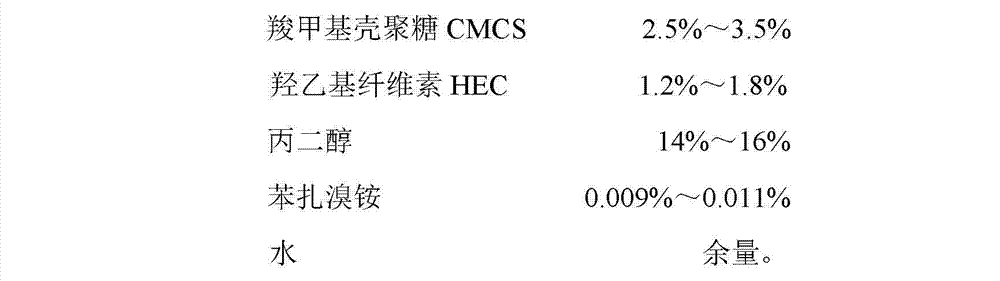

[0027] The hydrogel dressing provided in the present embodiment is made up of 3% carboxymethyl chitosan CMCS, 1.5% hydroxyethyl cellulose HEC, 15% propylene glycol, 0.01% benzalkonium bromide and water. The preparation process is as follows:

[0028] First, weigh each component according to the above ratio, wherein the carboxymethyl chitosan CMCS used is carboxymethyl chitosan CMCS with a 2% aqueous solution viscosity of 160-1000Cp at 20°C, and the hydroxyethyl cellulose used HEC is hydroxyethyl cellulose HEC with a viscosity of 10,000 to 50,000 Cp in a 2% aqueous solution at 20°C. Dissolve carboxymethyl chitosan CMCS in water, and heat the solution to 60°C, then add hydroxyethyl cellulose HEC into the solution and stir well. Propylene glycol and benzalkonium bromide are sequentially added to the above solution and fully stirred to obtain a final solution, and the hydrogel dressing can be prepared after the final solution is allowed to stand at room temperature for defoaming....

Embodiment 2

[0031] The hydrogel dressing provided in the present embodiment is made up of 2.7% carboxymethyl chitosan CMCS, 1.5% hydroxyethyl cellulose HEC, 16% propylene glycol, 0.011% benzalkonium bromide and water. The preparation process is as follows:

[0032] First, weigh each component according to the above ratio, wherein the carboxymethyl chitosan CMCS used is carboxymethyl chitosan CMCS with a 2% aqueous solution viscosity of 160-1000Cp at 20°C, and the hydroxyethyl cellulose used HEC is hydroxyethyl cellulose HEC with a viscosity of 10,000 to 50,000 Cp in a 2% aqueous solution at 20°C. Dissolve carboxymethyl chitosan CMCS in water, and heat the solution to 62°C, then add hydroxyethyl cellulose HEC into the solution and stir well. Propylene glycol and benzalkonium bromide are sequentially added to the above solution and fully stirred to obtain a final solution, and the hydrogel dressing can be prepared after the final solution is allowed to stand at room temperature for defoami...

Embodiment 3

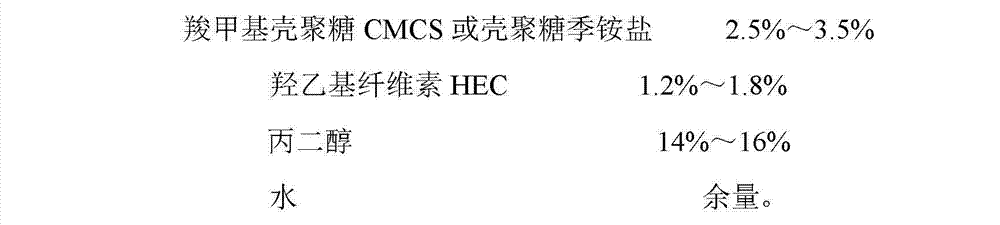

[0035] The hydrogel dressing provided in the present embodiment is made up of 3.1% chitosan quaternary ammonium salt, 1.7% hydroxyethyl cellulose HEC, 15.8% propylene glycol and water, and its preparation process is as follows:

[0036] First weigh each component according to the above ratio, wherein the chitosan quaternary ammonium salt used is the chitosan quaternary ammonium salt under the condition of molecular weight 500~500000, quaternary ammonium group substitution degree 0.1~1.0, the chitosan quaternary ammonium salt is 20 At 20°C, the viscosity of 2% aqueous solution is 1-1000 Cp, and the hydroxyethyl cellulose HEC used is hydroxyethyl cellulose HEC at 20°C, the viscosity of 2% aqueous solution is 10000-50000 Cp. Dissolve chitosan quaternary ammonium salt in water, and heat the solution to 58.5°C, then add hydroxyethyl cellulose HEC into the solution and stir well. Propylene glycol is added into the above solution and fully stirred to obtain a final solution, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com