CO2 absorption separation device and CO2 absorption separation method by hot potash process

A separation device, potash technology, applied in separation methods, through chemical separation, dispersed particle separation, etc., can solve problems such as complex process operation, environmental pollution, high energy consumption, etc., to overcome high cost and large loss , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

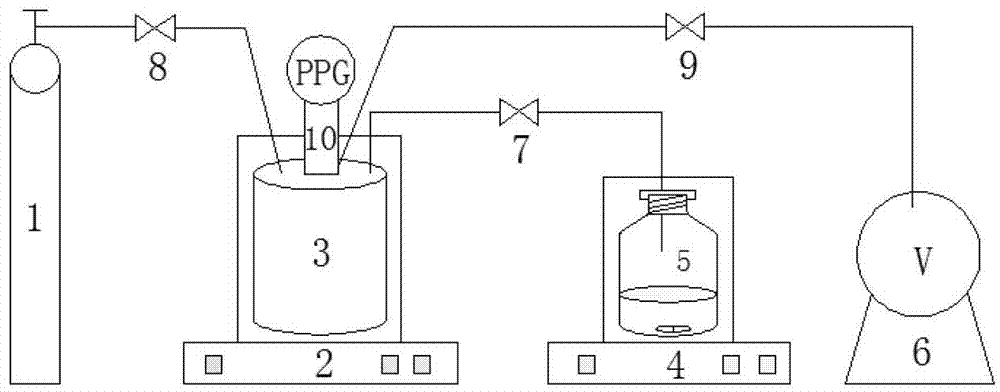

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 (comparative example)

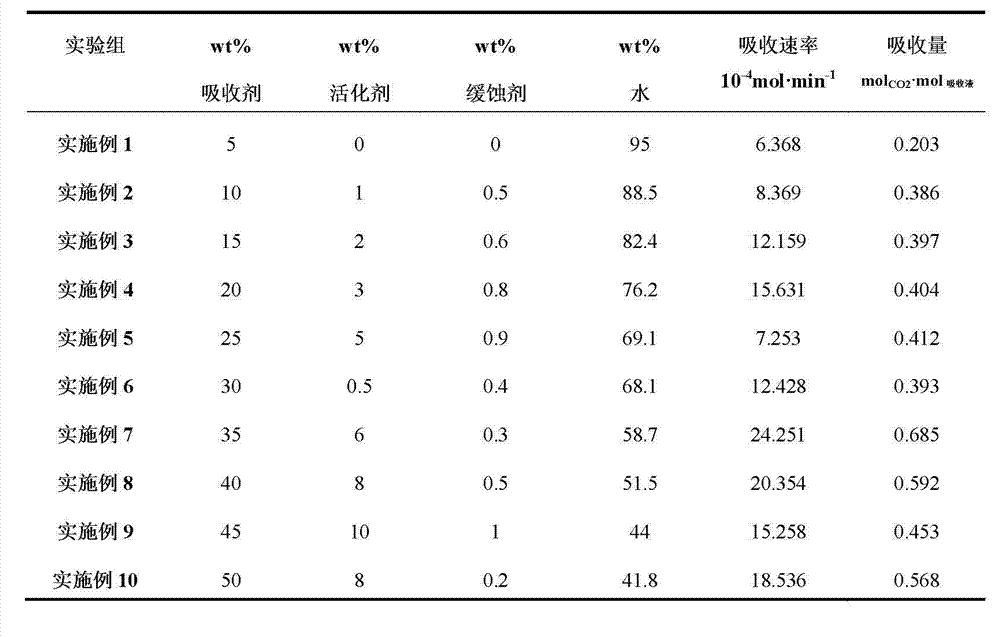

[0024] Take by weighing 2.5g salt of wormwood, 0g sodium metaborate, 0g sodium metavanadate, be made into 50g absorption solution, wherein potassium carbonate concentration is 5 wt%, join in the absorption bottle, add the rotor of constant temperature magnetic stirrer in the absorption bottle, Seal the absorption bottle, store gas in the gas storage tank to 150KPa, set the temperature of the water bath to 293K, and start the absorption experiment, in which CO 2 The absorption rate and absorption capacity are shown in Table 1.

Embodiment 2

[0026] Take by weighing 5g salt of wormwood, 0.5g sodium metaborate, 0.25g sodium metavanadate, be made into 50g absorption liquid, wherein the concentration of sodium carbonate is 10 wt%, join in the absorption bottle, add the temperature of constant temperature magnetic stirrer in the absorption bottle Rotor, seal the absorption bottle, store gas in the gas storage tank to 100KPa, set the temperature of the water bath to 303K, and start the absorption experiment, in which CO 2 The absorption rate and absorption capacity are shown in Table 1.

Embodiment 3

[0028] Take by weighing 7.5g sodium carbonate, 1g sodium metavanadate, 0.3g sodium metavanadate, make 50g absorption liquid, wherein the concentration of sodium carbonate is 15 wt%, join in the absorption bottle, add constant temperature magnetic stirrer in the absorption bottle rotor, seal the absorption bottle, store gas in the gas storage tank to 130KPa, set the temperature of the water bath to 365K, and start the absorption experiment, in which CO 2 The absorption rate and absorption capacity are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com