Preparation method for cellulose carbamic acid ester

A carbamate and cellulose technology, applied in the production field of cellulose derivatives, can solve the problems of increased cost, interference with the reaction between urea and cellulose, complicated operation procedures, etc., achieves improved solubility and rheology, and is beneficial to The effect of post-spinning and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

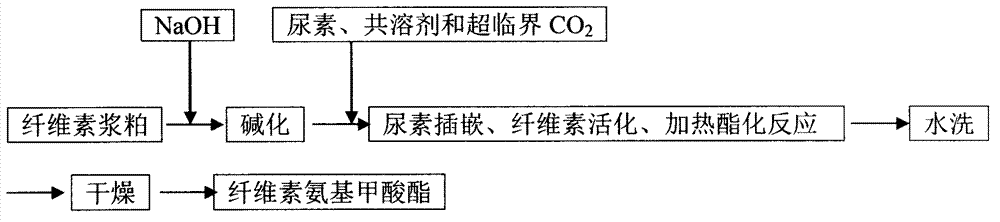

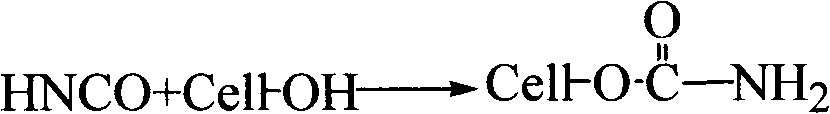

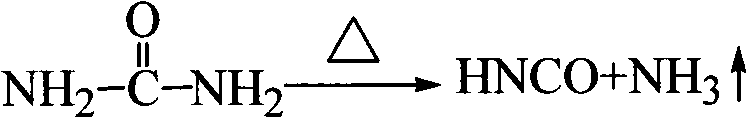

Method used

Image

Examples

Embodiment 1

[0043] Cotton pulp with a degree of polymerization of 560 and 10% sodium hydroxide solution was prepared at a bath ratio of 1:3, heated at 60°C for 5 hours, and then taken out and dried at room temperature. Take ethanol at a ratio of 1mol / L and add it to the reactor, weigh appropriate amounts of alkalized cotton pulp and urea at a ratio of 1:3, place them in a stainless steel basket in the reactor, and seal the reactor. Introduce carbon dioxide until the air in the device is exhausted, and close the release valve tightly. Then heat up to the reaction temperature of 140°C, then inject carbon dioxide through the high-pressure pump until the reaction pressure reaches 22Mpa, stop the pump, close the intake valve, and maintain the above reaction conditions for 3 hours to complete the esterification reaction. After the reaction is completed, the carbon dioxide in the reactor is emptied within 3 minutes, and the reactor is opened after the pressure drops to normal pressure, and the r...

Embodiment 2

[0045] Use wood pulp with a degree of polymerization of 850 and 15% sodium hydroxide solution at a bath ratio of 1:4 to prepare, heat at 80°C for 2 hours, and then take it out and dry it at room temperature. Take methanol at a ratio of 0.8mol / L and add it to the reactor, weigh an appropriate amount of alkalized wood pulp and urea at a ratio of 1:5, place them in a stainless steel basket, and seal the reactor. Introduce carbon dioxide until the air in the device is exhausted, and close the release valve tightly. Then heat up to the reaction temperature of 150°C, then inject carbon dioxide through the high-pressure pump until the reaction pressure reaches 25Mpa, stop the pump, close the intake valve, and maintain the above reaction conditions for 6 hours to complete the esterification reaction. After the reaction is completed, empty the carbon dioxide in the reactor within 3 minutes, open the reactor after the pressure drops to normal pressure, take out the raw materials, wash a...

Embodiment 3

[0047]Bamboo pulp with a degree of polymerization of 950 and 18% sodium hydroxide solution was prepared at a bath ratio of 1:5, heated at 50°C for 8 hours, and then taken out and dried at room temperature. Take n-butyraldehyde at a ratio of 1.2 mol / L and add it to the reactor, weigh an appropriate amount of alkalized bamboo pulp and urea at a ratio of 1:6, place them in a stainless steel basket in the reactor, and seal the reactor. Introduce carbon dioxide until the air in the device is exhausted, and close the release valve tightly. Then heat up to the reaction temperature of 155°C, then inject carbon dioxide through the high-pressure pump until the reaction pressure reaches 30Mpa, stop the pump, close the intake valve, and maintain the above reaction conditions for 4 hours to complete the esterification reaction. After the reaction is completed, the carbon dioxide in the reactor is emptied within 3 minutes, and the reactor is opened after the pressure drops to normal pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com