A kind of short-chain quaternary ammonium nitrogen modified mesoporous biochar and its preparation method and application

A chain quaternary amine nitrogen and biochar technology, which is applied in the field of short-chain quaternary amine nitrogen modified mesoporous biochar and its preparation and application, can solve the problems of poor conductivity and poor perchlorate adsorption effect, and achieve High use value, easy industrial application, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

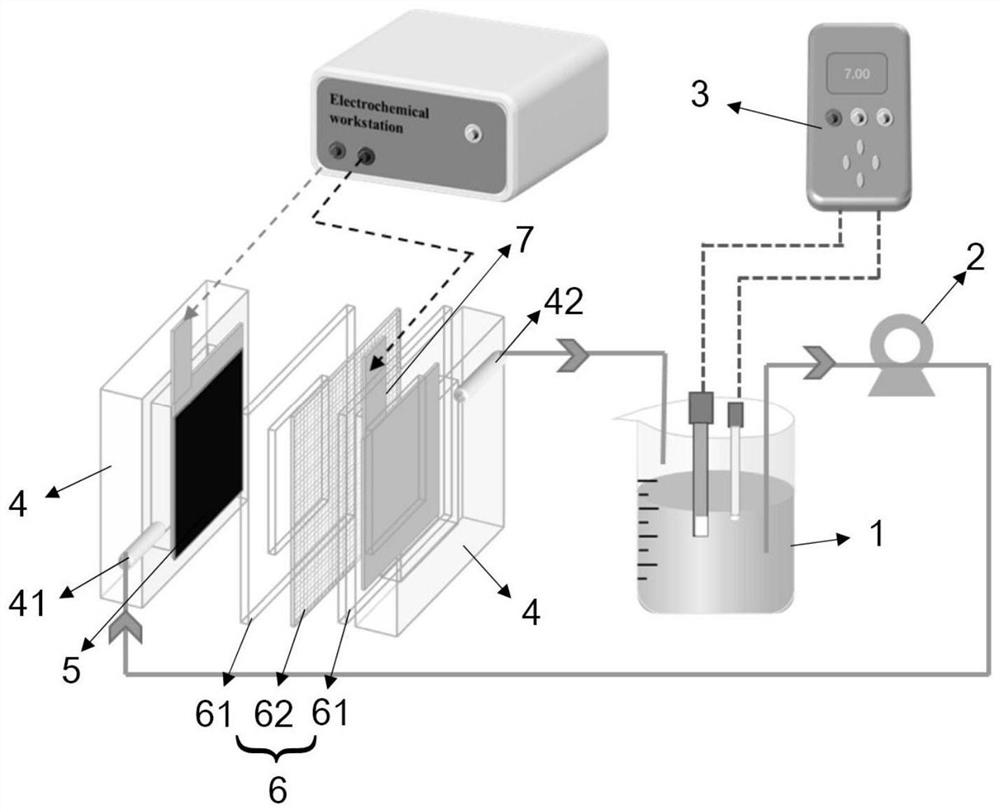

Method used

Image

Examples

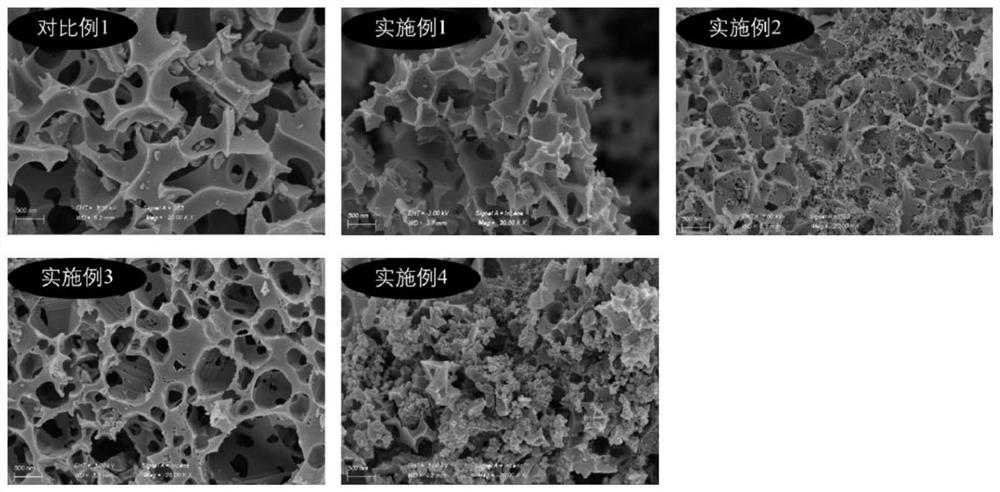

Embodiment 1

[0044] A preparation method of short-chain quaternary ammonium nitrogen modified mesoporous biochar, comprising the following steps:

[0045] (1) Wash the dust and other impurities on the surface of the raw bean dregs with distilled water, filter, and dry the obtained solid in an electric blast drying oven at 80°C until the quality is constant, and seal it for storage. Weigh 20 g of bean dregs and immerse in 290 mL of 1 mol / L potassium carbonate solution (prepared by dissolving potassium carbonate in water), mix evenly with a mixer, and continue stirring for 1 hour to obtain a mixed liquid of bean dregs.

[0046] (2) According to the quality of the zinc oxide microparticles being 10% of the total mass of the zinc oxide microparticles and the biomass material, get 5.56g, a mass concentration of 40% of the zinc oxide microparticles mixed solution and add the bean dregs mixed solution obtained in the step (1) , Sealed and stirred at room temperature for 24h. The impregnated samp...

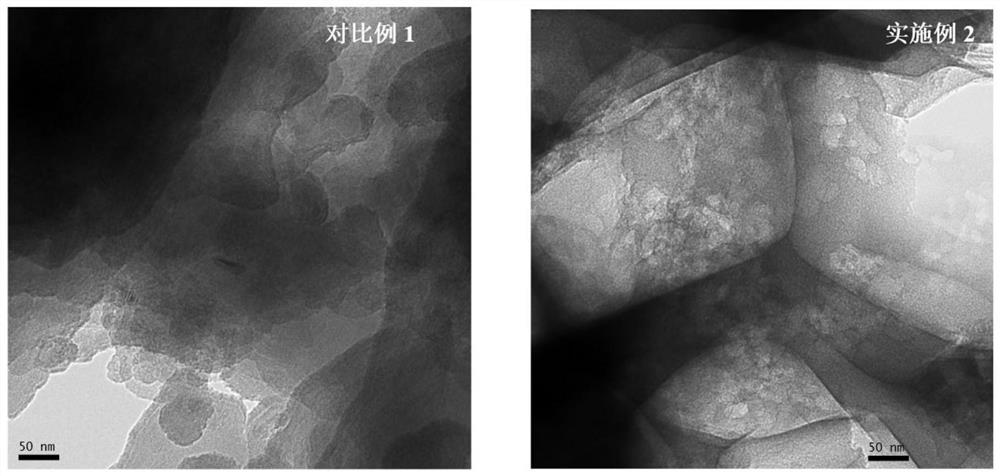

Embodiment 2

[0055] A preparation method of short-chain quaternary ammonium nitrogen modified mesoporous biochar, comprising the following steps:

[0056] (1) Wash the dust and other impurities on the surface of the raw bean dregs with distilled water, filter, and dry the obtained solid in an electric blast drying oven at 80°C until the quality is constant, and seal it for storage. Weigh 20 g of bean dregs and immerse in 290 mL of 1 mol / L potassium carbonate solution, mix evenly with a stirrer, and continue stirring for 1 hour to obtain a mixed liquid of bean dregs.

[0057] (2) According to the quality of the zinc oxide microparticles being 15% of the total mass of the zinc oxide microparticles and the biomass material, get 8.823g, a mass concentration of 40% of the zinc oxide microparticle mixed solution and add it to the okara mixed solution obtained in step (1). , Sealed and stirred at room temperature for 24h. The impregnated sample was dried in an electric blast drying oven at 105°C...

Embodiment 3

[0065] A preparation method of short-chain quaternary ammonium nitrogen modified mesoporous biochar, comprising the following steps:

[0066] (1) Wash the dust and other impurities on the surface of the raw bean dregs with distilled water, filter, and dry the obtained solid in an electric blast drying oven at 80°C until the quality is constant, and seal it for storage. Weigh 20 g of bean dregs and immerse in 290 mL of 1 mol / L potassium carbonate solution, mix evenly with a stirrer, and continue stirring for 1 hour to obtain a mixed liquid of bean dregs.

[0067] (2) According to the quality of the zinc oxide microparticles being 20% of the total mass of the zinc oxide microparticles and the biomass material, get 12.5g, a mass concentration of 40% of the zinc oxide microparticles mixed solution and add the bean dregs mixed solution obtained in the step (1) , Sealed and stirred at room temperature for 24h. The impregnated sample was dried in an electric blast drying oven at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com