Boron diffusion method of crystalline silicon solar cell

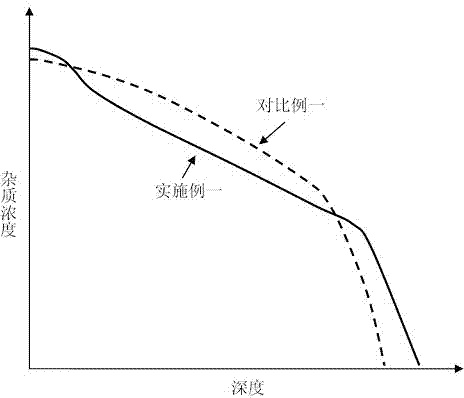

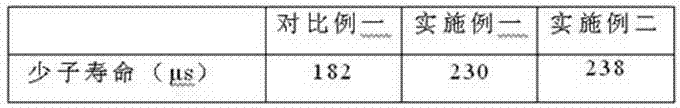

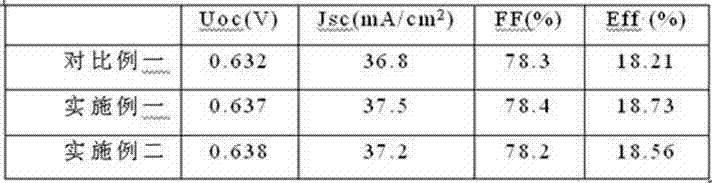

A solar cell and diffusion method technology, which is applied in the field of crystalline silicon solar cell manufacturing, can solve the problems of lattice distortion of silicon atoms, affect cell performance, reduce minority carrier lifetime, etc., and achieve the effects of easy operation, improving battery performance, and improving minority carrier lifetime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A boron diffusion method for a crystalline silicon solar cell includes the following steps:

[0033] (1) Put the suede silicon wafer into the diffusion furnace and heat it up to 900℃; pass the boron source, oxygen and nitrogen for boron diffusion, the diffusion time is 25 min; boron source BBr 3 The flow rate is 700mL / min, O 2 The flow rate is 600mL / min, and the nitrogen flow rate is 10L / min;

[0034] (2) In a nitrogen atmosphere, the temperature is increased to 1050°C at a rate of 10°C / min. During the heating process, N 2 The flow rate is 10L / min, and the temperature reaches 1050℃ to pass BBr 3 , Oxygen and nitrogen are diffused, the diffusion time is 40min; BBr 3 The flow rate is 50mL / min, O 2 Flow rate is 100mL / min, N 2 The flow rate is 10L / min;

[0035] (3) Keep the temperature of step (2) for boron diffusion, the diffusion time is 10 min; BBr 3 The flow rate is 1000 mL / min; the oxygen flow rate is 800 mL / min, and the nitrogen flow rate is 10L / min;

[0036] (4) Cool down and...

Embodiment 2

[0038] A boron diffusion method for a crystalline silicon solar cell includes the following steps:

[0039] (1) Put the suede silicon wafer into the diffusion furnace and heat it to 950℃; pass the boron source and oxygen to diffuse the boron, the diffusion time is 25 min; the boron source BBr 3 The flow rate is 700mL / min, O 2 The flow rate is 600mL / min, and the nitrogen flow rate is 10L / min;

[0040] (2) Stop the power source, keep at 950℃, keep for 40min under nitrogen atmosphere; N 2 The flow rate is 10L / min;

[0041] (3) Enter the boron source for boron diffusion, the diffusion time is 10 min; BBr 3 The flow rate is 1000 mL / min; the oxygen flow rate is 800 mL / min, and the nitrogen flow rate is 10L / min;

[0042] (4) Cool down and complete diffusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com