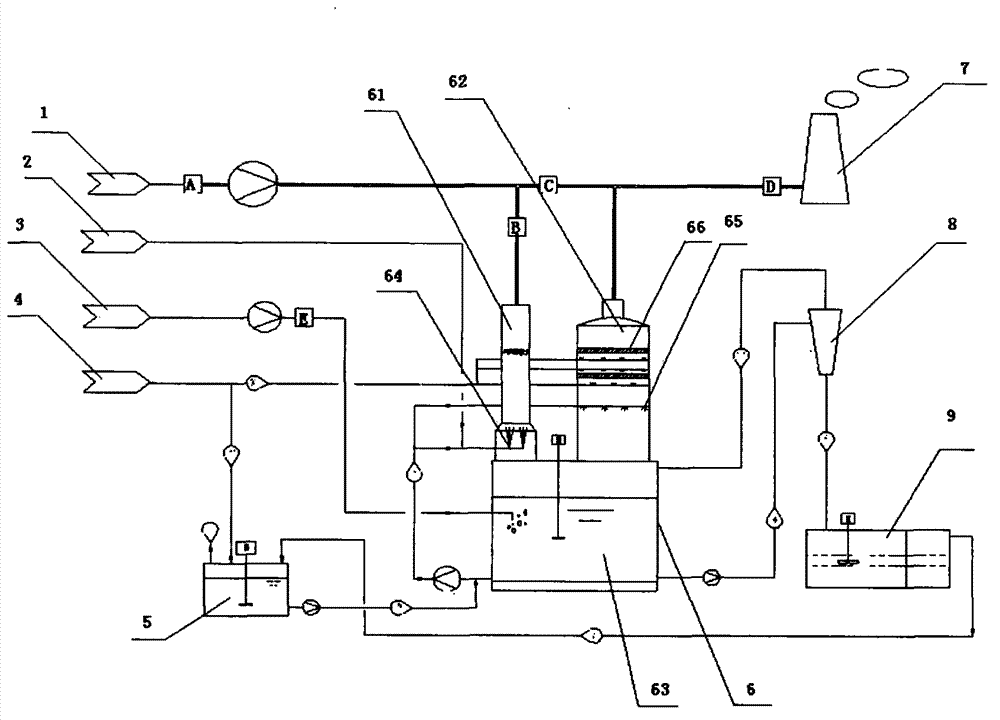

High-temperature atomization wet denitration process system and denitration method

A technology of wet denitrification and process system, which is applied in the field of process system for denitrification of flue gas or tail gas under the application of flue gas denitrification process of small and medium-sized boilers, and can solve the problems of unfavorable resource recycling, high cost of wastewater treatment, and oxidant Problems such as large amount of use, to achieve the effect of high purchase cost, low risk, and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Taking a boiler (10t / h) as an example, the denitrification process is carried out according to the high-temperature atomization wet denitrification process system and the denitrification method of the present invention. In the experiment, the absorbent slurry includes 5wt% limestone, 2.5wt% active coke, and 0.5wt% ferric oxide catalyst; the ratio of absorbent slurry to flue gas is 15L / m 3 . In the first reaction step, the flue gas flow rate is 20-25m / s. In the second reaction step, the flue gas flow rate is 3-5m / s; the temperature of the high-temperature steam is preferably 350°C.

[0040] The basic data obtained from the test are as follows:

[0041] Total flue gas flow: 12000m 3 / h; flue gas containing NOx 600mg / m 3 . Net flue gas contains NOx 100-120mg / m 3 , the denitrification rate reaches 80-85%.

Embodiment 2

[0043] Taking a boiler (20t / h) as an example, the denitration treatment is carried out according to the high-temperature atomization wet denitration process system and the denitration method of the present invention. In the experiment, the absorbent slurry included 1.2wt% limestone, 3.5wt% active coke, and 1.0wt% ferric oxide catalyst; the ratio of absorbent slurry to flue gas was 15L / m 3 . In the first reaction step, the flue gas flow rate is 20-25m / s. In the second reaction step, the flue gas flow rate is 3-5m / s; the temperature of the high-temperature steam is preferably 350°C.

[0044] The basic data obtained from the test are as follows:

[0045] Total flue gas flow: 25000m 3 / h; flue gas containing NOx 800mg / m 3 . Net flue gas contains NOx 120-150mg / m 3 , The denitrification rate reaches more than 80%.

Embodiment 3

[0047] Taking a boiler (10t / h) as an example, the denitrification process is carried out according to the high-temperature atomization wet denitrification process system and the denitrification method of the present invention. In the experiment, the absorbent slurry includes 4.5wt% limestone, 2.5wt% active coke, 0.2wt% catalyst; the catalyst is Fe 2 o 3 、TiO 2-x and Cu 2 Composition composed of B, wherein X=0.5, and the content of each component is Fe 2 o 3 Accounting for 50wt%, TiO 2-x 25wt%, Cu 2 B accounts for 25 wt%.

[0048] The ratio of absorbent slurry to flue gas is 15L / m 3 . In the first reaction step, the flue gas flow rate is 20-25m / s. In the second reaction step, the flue gas flow rate is 3-5m / s; the temperature of the high-temperature steam is preferably 350°C.

[0049] The basic data obtained from the test are as follows:

[0050] Total flue gas flow: 25000m 3 / h; flue gas containing NOx 600mg / m 3 . Net flue gas contains NOx 80-100mg / m 3 , The deni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com