Preparation method of polyacrylonitrile chelating resin adsorbent

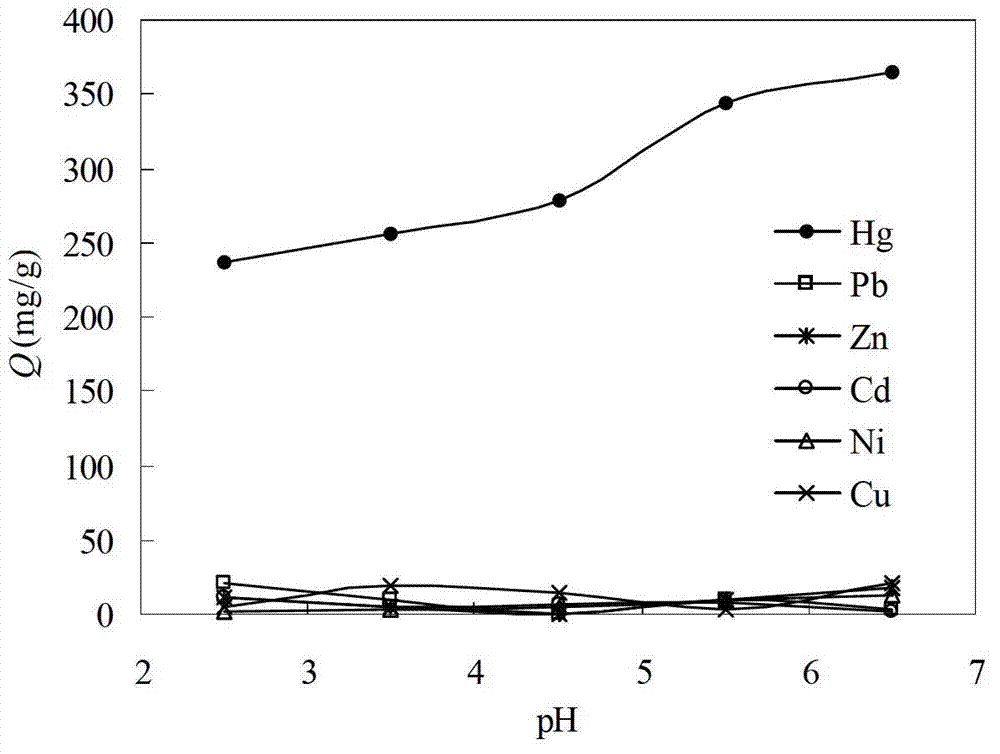

A chelating resin, polyacrylonitrile technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low elution rate, poor mechanical strength, low stability, etc., and achieve good chemical stability, thermal stability, etc. Good stability and fast adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

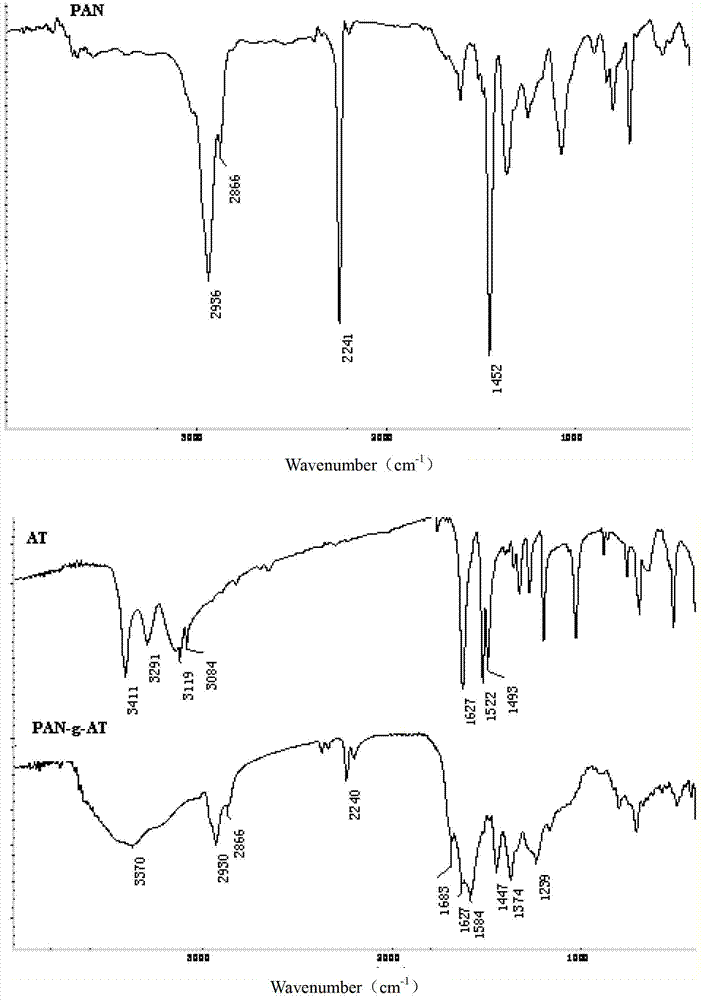

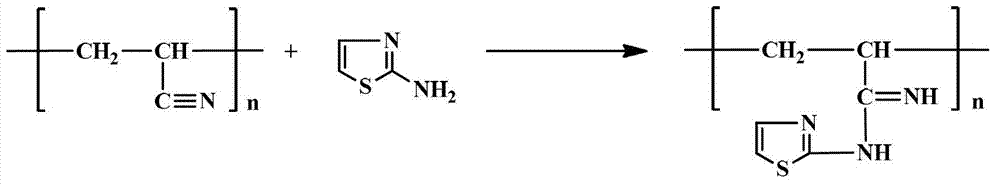

[0048] Embodiment 1, a kind of preparation method of novel polyacrylonitrile chelating resin adsorbent, take polyacrylonitrile microsphere (D-160 type macroporous adsorption resin) as matrix, 2-aminothiazole (AT) as ligand, Carry out chemical grafting to polyacrylonitrile microsphere, carry out the following steps in sequence:

[0049] ① Weigh 500 mg of polyacrylonitrile microspheres, transfer them into a 500 mL three-necked bottle, add 300 mL of reaction solvent --- DMF, and soak overnight (that is, soak for 24 hours to fully swell the polyacrylonitrile microspheres) ;

[0050] ②. Add 3970.4 mg of ligand --- 2-aminothiazole (AT) and a small amount of catalyst --- sodium metal (1020 mg) to the result of step ① (that is, the swollen polyacrylonitrile microspheres), Under the protection of nitrogen, heat and stir (250r / min) at 100°C for 8 hours to obtain the modified polyacrylonitrile chelating resin;

[0051] 3., the polyacrylonitrile chelating resin after the modification of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com