Novel purification technology for producing liquid sulfur dioxide by pure oxygen method

A liquid sulfur dioxide and sulfur dioxide technology, applied in inorganic chemistry, sulfur compounds, chemical instruments and methods, etc., can solve the problems of not meeting the first-class standard, entering sulfur particles, affecting production, etc., to reduce system resistance and improve. Continuity, reducing the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

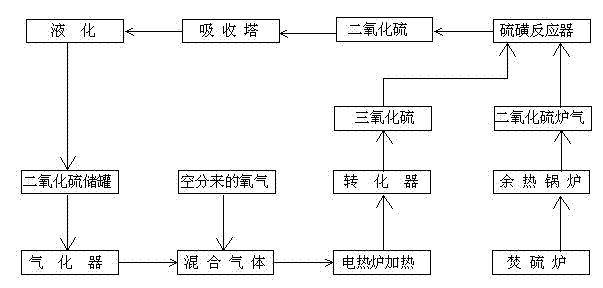

[0020] Use a pump to pump 0.31T / h of liquid sulfur into the sulfur incinerator, and inject 300m3 / h of oxygen into the sulfur incinerator, and control the temperature at about 850°C for incineration to produce sulfur dioxide gas.

[0021] Press a small amount of sulfur dioxide in the sulfur dioxide storage tank into the gasifier, use 80℃ hot water to heat the liquid sulfur dioxide into a gaseous state, and control the volume flow of sulfur dioxide at 0.15m3 / h according to the amount of sublimed sulfur, and the volume of oxygen from the air separation The flow ratio is 8:1 to mix into a mixed gas. The mixed gas is heated to 410℃ by an electric heating furnace and then sent to the converter to be converted into sulfur trioxide. During the conversion process, the inlet temperature of the converter is controlled at 430°C and the outlet temperature is controlled at ≤600℃.

[0022] Add 98% sulfuric acid in the sulfur reactor to the observation mirror of the reactor, then increase the temp...

Embodiment 2

[0025] Use a pump to pump liquid sulfur 0.52T / h into the sulfur incinerator, and inject 500m3 / h of oxygen into the sulfur incinerator, and control the temperature at about 850°C for incineration to produce sulfur dioxide gas.

[0026] Press a small amount of sulfur dioxide in the sulfur dioxide storage tank into the gasifier, use 80℃ hot water to heat the liquid sulfur dioxide into gaseous state, and control the volume flow of sulfur dioxide at 0.2m3 / h according to the amount of sublimed sulfur, and the volume of oxygen from air separation The flow rate ratio is 8:1 to mix into a mixed gas. The mixed gas is heated to 420℃ by an electric heating furnace and then sent to the converter to be converted into sulfur trioxide. During the conversion process, the inlet temperature of the converter is controlled at 420°C and the outlet temperature is controlled at ≤600℃.

[0027] Add 98% sulfuric acid by mass ratio into the sulfur reactor to the observation mirror of the reactor, then increa...

Embodiment 3

[0030] Use a pump to drive 1.05T / h of liquid sulfur into the sulfur incinerator, and inject 1000m3 / h of oxygen into the sulfur incinerator, and control the temperature at about 850℃ for incineration to produce sulfur dioxide gas.

[0031] Press a small amount of sulfur dioxide in the sulfur dioxide storage tank into the gasifier, and use 80°C hot water to heat the liquid sulfur dioxide into a gaseous state. According to the amount of sublimed sulfur, control the volume flow of sulfur dioxide to 0.4m3 / h, and the oxygen from air separation by volume The flow ratio is 8:1 to mix into a mixed gas. The mixed gas is heated to 430℃ by an electric heating furnace and then sent to the converter to be converted into sulfur trioxide. During the conversion process, the inlet temperature of the converter is controlled at 430°C and the outlet temperature is controlled at ≤600℃.

[0032] Add 98% sulfuric acid by mass ratio into the sulfur reactor to the observation mirror of the reactor, then inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com