Method for removing high concentration phosphorus in glyphosate wastewater

A glyphosate wastewater, high-concentration technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of high cost, poor stability, and low removal effect of high-concentration phosphorus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

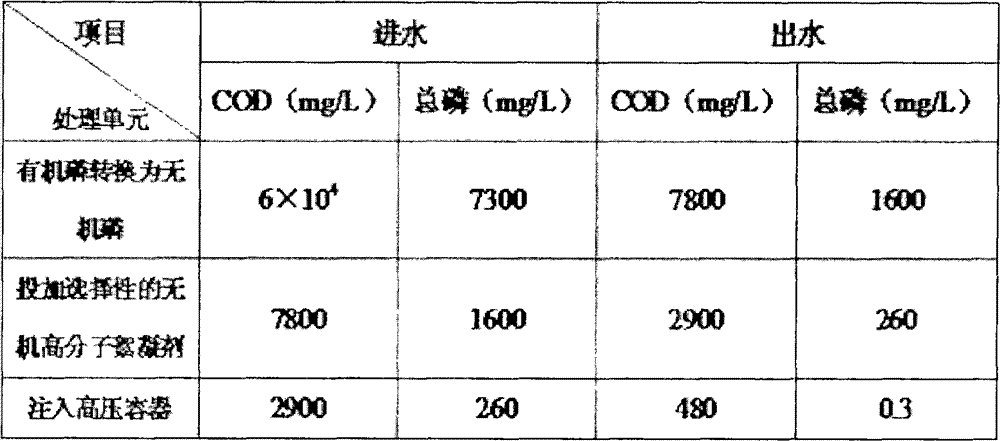

Embodiment 1

[0021] First add a certain amount of one of sodium thiosulfate, sodium borohydride and stannous chloride as a reducing agent to the glyphosate wastewater to maintain the dissolved oxygen in the wastewater at 0.3mg / L; Add extracellular hydrolase and nicotinamide adenine dinucleotide phosphate, keep the wastewater temperature at 35°C for 38 hours; then use one of caustic soda, caustic soda, and calcium hydroxide as an alkali to adjust the pH value of the wastewater It is 7.3; add 350ppm to the waste water to carry out flocculation and sedimentation with one of polyaluminum iron phosphate, polyaluminum iron phosphate and polysilicate aluminum chloride sulfate as inorganic macromolecule flocculant; in the settled waste water Add 100ppm of sodium hypochlorite, 65ppm of polyepoxysuccinic acid, and 70ppm of glycerol into the high-pressure container, and blow in air to keep the total pressure in the container at 5.0MPa; finally, open the channel of the high-pressure container and relea...

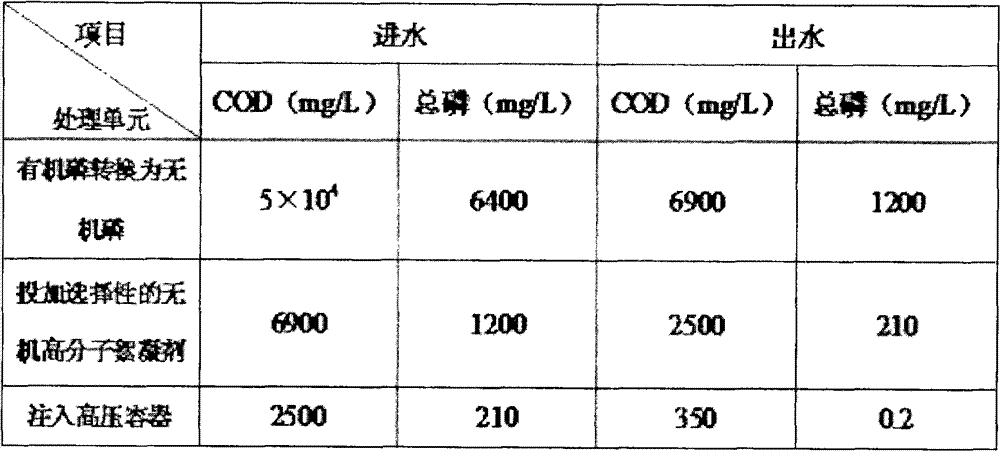

Embodiment 2

[0025] First add a certain amount of one of sodium thiosulfate, sodium borohydride, and stannous chloride to the glyphosate wastewater as a reducing penalty to maintain the dissolved oxygen in the wastewater at 0.5mg / L; Add extracellular hydrolase and nicotinamide adenine dinucleotide phosphate, keep the wastewater temperature at 37°C for 45 hours; then use one of caustic soda, caustic soda, and calcium hydroxide as an alkali to adjust the pH value of the wastewater It is 7.8; add 450ppm in the waste water with polyaluminum ferric phosphate, polyaluminum ferric silicate, polysilicate aluminum ferric chloride sulfate as inorganic macromolecule flocculation penalty for flocculation and sedimentation; in the settled waste water Add 150ppm of sodium hypochlorite, 95ppm of polyepoxysuccinic acid, and 75ppm of glycerol into the high-pressure container, and blow in air to keep the total pressure in the container at 5.9MPa; finally, open the high-pressure container channel and release ...

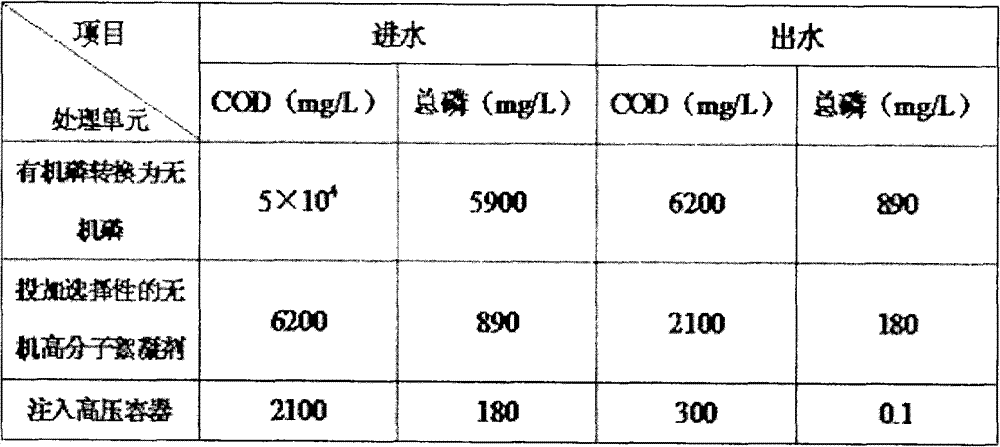

Embodiment 3

[0029] First add a certain amount of one of sodium thiosulfate, sodium borohydride and stannous chloride as a reducing agent to the glyphosate wastewater to maintain the dissolved oxygen in the wastewater at 0.4mg / L; Add extracellular hydrolase and nicotinamide adenine dinucleotide phosphate to keep the wastewater temperature at 36C for 40 hours; then use one of caustic soda, caustic soda and calcium hydroxide as an alkali to adjust the pH value of the wastewater 7.3; Add 400ppm of one of polyaluminum iron phosphate, polyaluminum iron phosphate and polysilicate aluminum chloride sulfate to the wastewater as an inorganic polymer flocculant for flocculation and sedimentation; Add 120ppm of sodium hypochlorite, 70ppm of polyepoxysuccinic acid, and 70ppm of glycerol, inject it into the high-pressure container, and blow in air to keep the total pressure in the container at 5.8MPa; finally, open the channel of the high-pressure container to release the waste water into the pool Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com