Method for preparing wide-temperature-range high-frequency high-damping rubber materials

A damping rubber, high frequency technology, which is applied in the preparation of wide temperature range, wide frequency and high damping rubber materials, and the preparation of rubber-based damping materials, can solve the problem of poor high temperature stability of damping materials, difficulty in removing organic solvents, and reduce damping peaks. Height and other issues, to achieve the effect of simple and reliable processing, improved mechanical properties, and improved damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

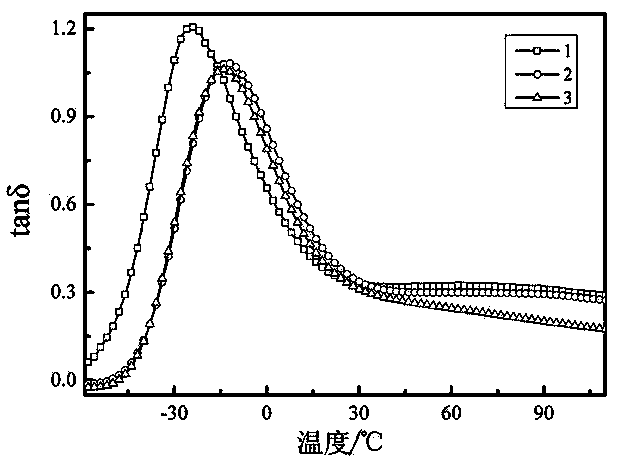

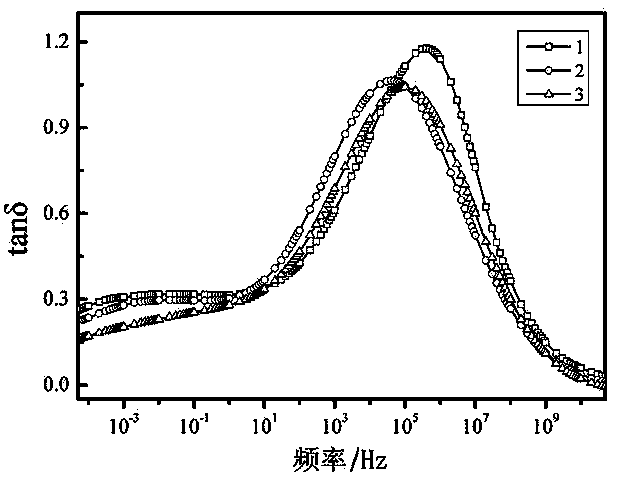

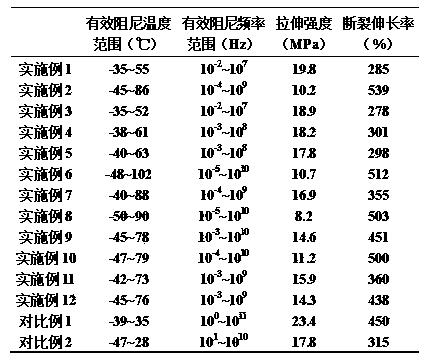

Embodiment 1

[0037] At 50°C, 100g of ENR-40 type epoxidized natural rubber was masticated on the open mill for 3 minutes, and then covered with rolls, adding 8g of zinc oxide, 5g of stearic acid, 5g of basic magnesium carbonate, 40g of N220 type carbon black, 8 g of dibutyl phthalate, 0.1 g of acidified multi-walled carbon nanotubes, 4 g of dibenzothiazole disulfide (abbreviation: DM), and 30 g of 2402 tert-butylphenol formaldehyde resin were mixed evenly to prepare a rubber compound; After standing for 8 hours, at a temperature of 150°C and a pressure of 100kgf / cm 2 Under the condition of vulcanizing on a flat vulcanizing machine for 45 minutes, a rubber material with wide temperature range, wide frequency and high damping can be obtained.

Embodiment 2

[0039]At 50°C, 100g of ENR-50 type epoxidized natural rubber was masticated on the open mill for 3 minutes, and then covered with rolls, adding 6g of zinc oxide, 1g of stearic acid, 1g of basic magnesium carbonate, 30g of N330 carbon black, Acidified multi-walled carbon nanotubes 0.2g, dibenzothiazole disulfide 1g, stannous chloride 0.2g, SP-1045 tert-octylphenol formaldehyde resin 5g were mixed evenly, and prepared into a rubber compound; after standing for 12 hours , at a temperature of 150°C and a pressure of 150kgf / cm 2 Next, vulcanize on a flat vulcanizing machine for 60 minutes to produce a rubber material with wide temperature range, wide frequency and high damping.

Embodiment 3

[0041] At 80°C, put 1000g of ENR-40 epoxidized natural rubber, 1500g of N330 carbon black, and 100g of dibutyl phthalate into an internal mixer and mix for 10 minutes to obtain a masterbatch, which was cooled at room temperature and weighed. Get the above-mentioned masterbatch 260g, then add acidified multi-walled carbon nanotubes 0.05g, zinc oxide 5g, stearic acid 2g, basic magnesium carbonate 1g, dibenzothiazole disulfide 5g, SP-1055 bromine on the open mill Mix 30g of methyl tert-octylphenol formaldehyde resin evenly to prepare a rubber compound; after standing for 12 hours, at a temperature of 160°C and a pressure of 100kgf / cm 2 Next, vulcanize on a flat vulcanizing machine for 25 minutes to produce a rubber material with wide temperature range, wide frequency and high damping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damping temperature range | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com