Luminescent material of naphthoic acid functionalized polymer and rare earth complex and preparation method of luminescent material

A technology of rare earth complexes and luminescent materials, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem of low fluorescence emission intensity, achieve the effect of enhancing luminescence performance and strengthening energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

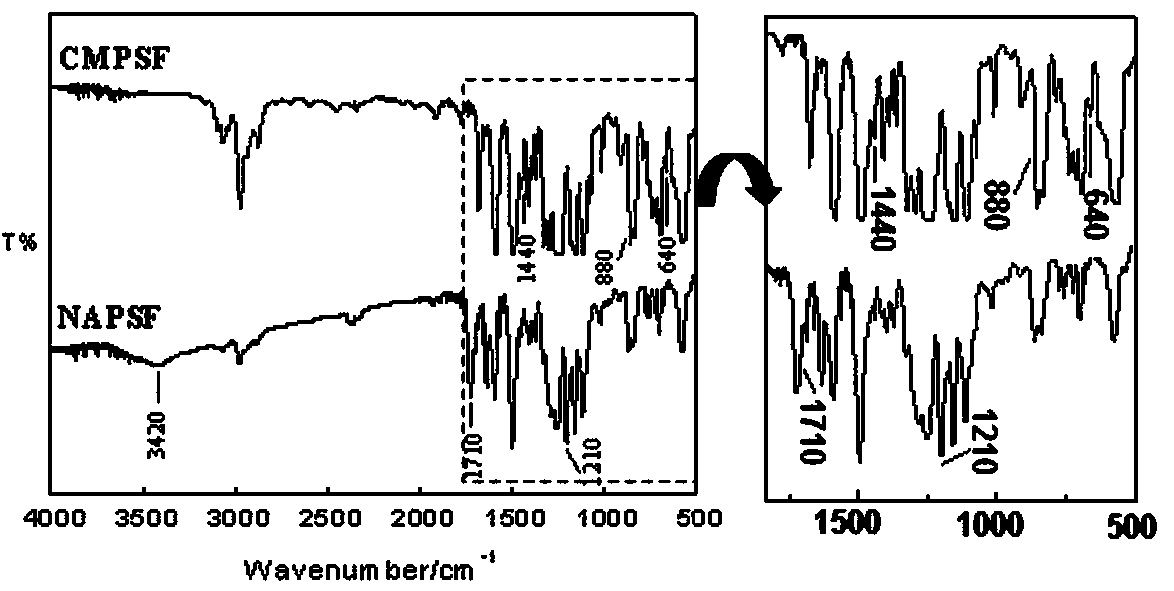

[0025] Example 1: In a four-necked flask, add 0.5g chloromethylated polysulfone (CMPSF) and 50mL dimethyl sulfoxide to fully dissolve CMPSF, then add 0.16g of 6-hydroxy-2-naphthoic acid and 0.10 g Anhydrous sodium carbonate, react at a constant temperature of 50°C for 8 hours, acidify the system with dilute hydrochloric acid, then precipitate the polymer with ethanol, wash with water, and dry to obtain the modified polysulfone NAPSF with naphthoic acid (NA) ligands bonded to the side chain. The bonding amount of naphthoic acid was 1.62 mmol / g.

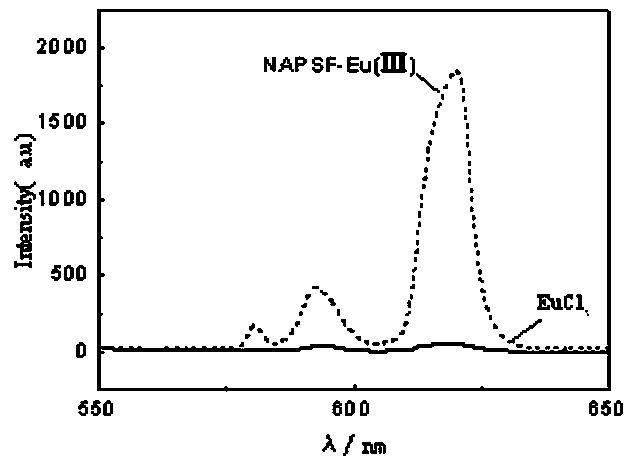

[0026] In a four-neck flask, add 0.2g NAPSF and dissolve in 50mL dimethylformamide, adjust the pH to 6~7 with NaOH solution, then add 0.04g europium trichloride crystals, and react at 50°C for 8h. After the reaction, the polymer was precipitated with ethanol, washed with water, and dried to obtain the polymer-rare earth binary complex NAPSF-Eu(Ⅲ).

[0027] With 343 nm as the excitation wavelength, the fluorescence emission spectrum of...

Embodiment 2

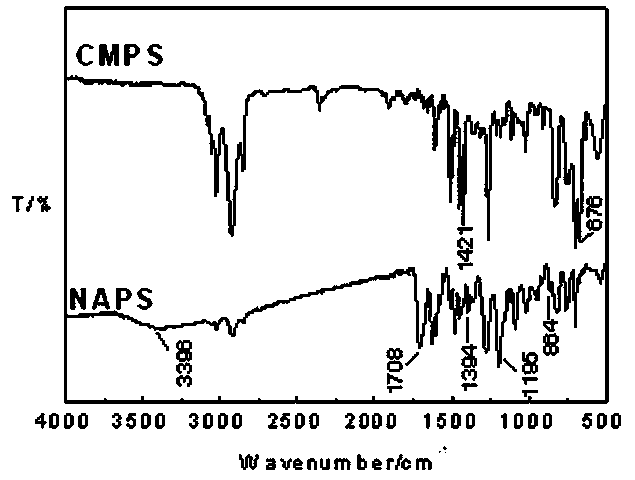

[0028]Example 2: In a four-necked flask, add 0.5g chloromethylated polystyrene (CMPS) and 50mL dimethyl sulfoxide to fully dissolve the PS, then add 0.32g 6-hydroxy-2-naphthoic acid and 0.36g Anhydrous sodium carbonate, constant temperature reaction at 70 ℃ for 8h, acidify the system with dilute hydrochloric acid, then precipitate the polymer with ethanol, wash with water, and dry to obtain the modified polystyrene NAPS with side chain bonded naphthoic acid (NA) ligand. The bonding amount of naphthoic acid was 3.02 mmol / g.

[0029] In the four-neck flask, add 0.5g NAPS and dissolve it in 50mL DMSO, adjust the pH=6~7 with NaOH solution, then add 0.18g europium trichloride crystal (0.245mmol), and react at 50 ℃ for 8h. Using ethanol as a precipitant, the polymer was precipitated, washed with water, and dried to obtain the polymer-rare earth binary complex NAPS-Eu(Ⅲ).

[0030] With 343 nm as the excitation wavelength, the fluorescence emission spectrum of the complex NAPS-Eu(Ⅲ) ...

Embodiment 3

[0031] Example 3: In a four-neck flask, add 0.45g chloromethylated polysulfone (CMPSF) and 50mL dimethylacetamide to fully dissolve CMPSF, then add 0.25g of 6-hydroxy-2-naphthoic acid and 0.21 g Anhydrous sodium carbonate, react at a constant temperature of 60°C for 8 hours, acidify the system with dilute hydrochloric acid, then precipitate the polymer with ethanol, wash with water, and dry to obtain the modified polysulfone NAPSF with naphthoic acid (NA) ligands bonded to the side chain. The bonding amount of naphthoic acid was 1.57 mmol / g.

[0032] In a four-neck flask, add 0.3g NAPSF and dissolve in 50mL dimethylacetamide, adjust the pH to 6~7 with NaOH solution, then add 0.08g terbium trichloride crystals, and react at 50°C for 8h. After the reaction, the polymer was precipitated with ethanol, washed with water, and dried to obtain the polymer-rare earth binary complex NAPSF-Tb (Ⅲ).

[0033] With 295nm as the excitation wavelength, the fluorescence emission spectrum of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com