Three-dimensional pore shading decorative ceramic brick and manufacturing method thereof

A manufacturing method and technology of ceramic tiles, applied in the direction of ceramic layered products, chemical instruments and methods, layered products, etc., can solve the problems of a single three-dimensional hole decoration effect, which cannot meet people's needs for rich decoration effects, etc. Dyeing decoration, enriching decorative effect, reducing the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

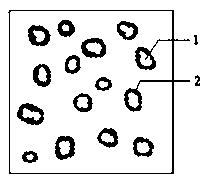

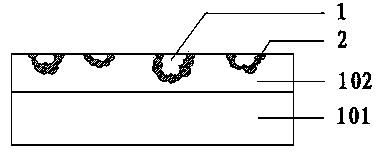

[0032] 1. Select plant fibers such as hemp rope and bagasse as raw materials, and after crushing and screening, select the "core" of the pore-forming material with a length of about 15mm to 50mm;

[0033] 2. Configure the bleeding dyeing agent, which can be used commonly used pink (potassium permanganate), blue (cobalt sulfate), dark red (ferric chloride), dark brown (manganese chloride), etc. The configuration is specifically adding kaolin ball-milled slurry with a mass percentage of 10% to 20%, and the moisture content of the slurry is 70% to 80%. For other chromogenic oxides, in order to obtain richer colors, two or more chromogenic water-soluble salts can be used in combination in proportion;

[0034] 3. After preliminarily soaking the "nuclei" of the screened pore-forming material in the bleed dyeing agent, it is dried to harden the pore-forming material;

[0035] 4. Mix the dyed porous material into the textured material, and press the textured material to make bricks; ...

Embodiment 2

[0040] The production method of this example is the same as that of the example, the difference lies in the "core" of the pore-forming material. This example uses baked leaves (in the shape of tea rolls), dry straw, rice husk, paper balls, etc. The hollow organic matter serves as the "core" of the pore-forming material, thereby increasing the diversity of pore shapes; at the same time, the firing cycle is 100 minutes, and the firing temperature is 1205°C.

Embodiment 3

[0042] The production method of this embodiment is the same as that of the embodiment, the difference lies in the "nucleus" of the pore-forming material. This embodiment uses bird droppings, chicken manure, cow dung, straw paper, feed, etc. that have been processed through the animal digestive system or artificially. The plant fiber acts as the "core" of the porogen, thereby increasing the diversity of pore shapes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com