Cover plate-free carbon nanotube device structure and manufacturing method thereof

A carbon nanotube and device structure technology, applied in the field of nanoelectronic devices and sensors, can solve problems such as limited application range, difficulty in batch production, and high difficulty in device production, so as to simplify the process flow, improve device yield, device structure and The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation steps of the present invention will be further described below in conjunction with the accompanying drawings, which are not drawn to scale for the convenience of illustration.

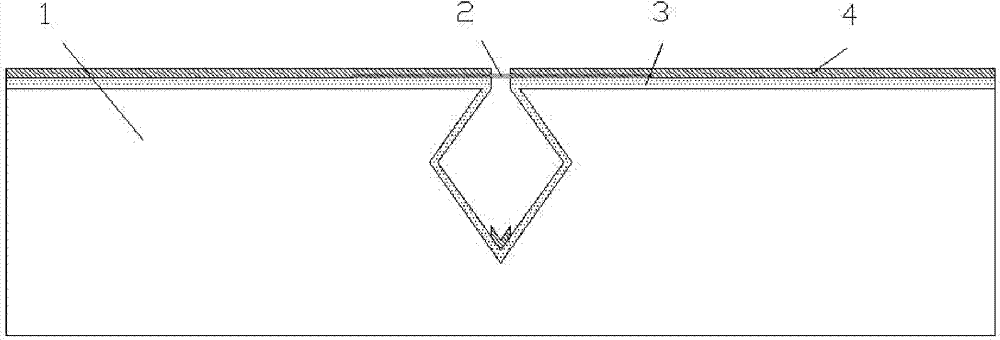

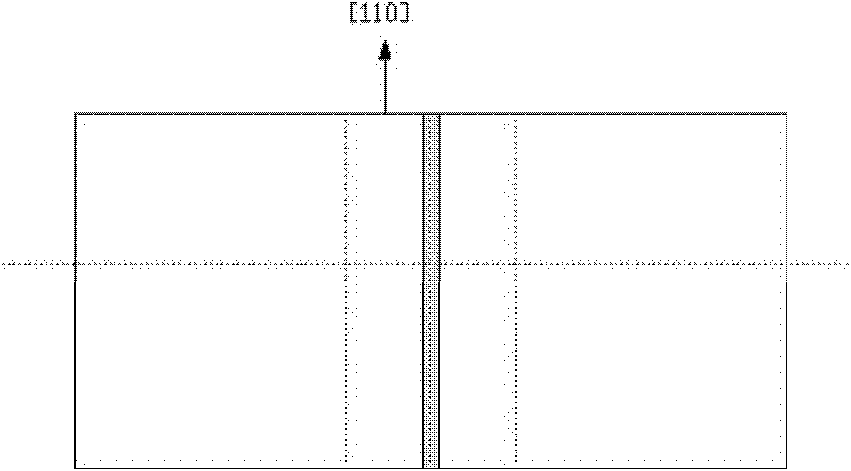

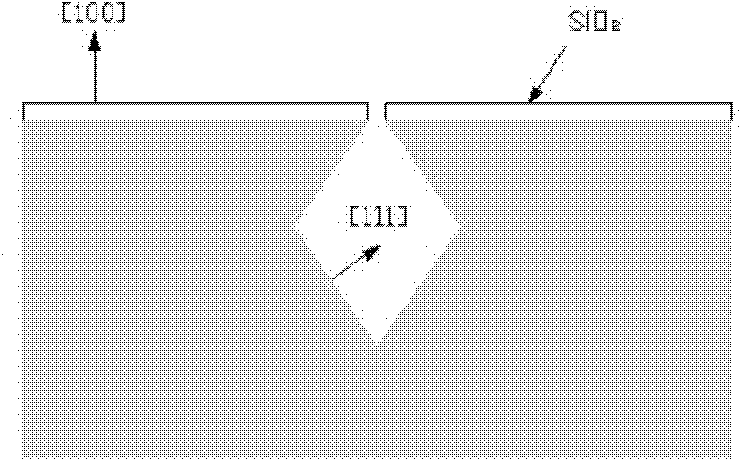

[0031] This embodiment provides a carbon nanotube sensor structure, which can be combined with MEMS technology as a carbon nanotube infrared and THz detector structure. The device structure is fabricated on a single crystal silicon substrate with a orientation, and the structure is as follows figure 1 As shown, it includes (100) single crystal silicon substrate 1 , horizontal single-walled carbon nanotube array 2 , oxide layer 3 , and metal electrode 4 in four parts. Wherein, the near-rhombic section groove in the (100) single crystal silicon substrate 1 is obtained by anisotropic wet etching on the basis of dry etching the deep groove. The opening of the groove is along the crystal direction, and the surface after wet etching is the (111) surface, such as Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com