Method for preparing antimicrobial medical polymer material

A technology of polymer materials and plasma, which is applied in the field of preparation of medical polymer materials, can solve the problems of unsustainable antibacterial effect, poor binding force of antibacterial agents, poor antibacterial persistence, etc., and achieve enhanced binding force and stable surface structure , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

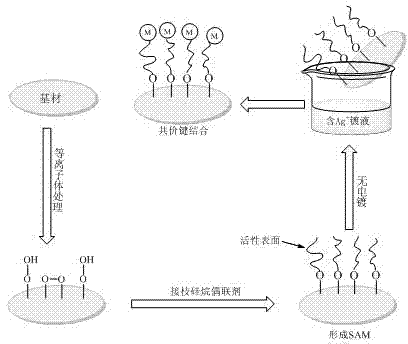

[0036] Implement the preparation method of a kind of antibacterial medical polymer material provided by the present invention, this method adopts plasma-self-assembled monolayer film and electroless plating combination technology to prepare antibacterial medical polymer material, carry out according to the following steps:

[0037] Cut the silica gel sheet with a thickness of 0.05mm into a 5cm×5cm sheet, place it in acetone solution, a certain concentration of alkali solution, an acid solution, and deionized water for a certain period of ultrasonic cleaning, take it out and dry it for later use; after that, the pretreatment The final silica gel sheet is placed on the processing table of the vacuum chamber of the plasma equipment, sealed, and vacuumized to 6×10 0 Pa; Preheat for 10 minutes, and then inject 20.0 SCCM of helium to finally maintain the vacuum degree in the vacuum chamber at 10 Pa. Turn on the plasma source, keep its power at 50W, and the processing time is 10min; ...

Embodiment 2

[0040] The antibacterial medical polymer material is prepared by combining plasma-self-assembled monolayer film and electroless plating, including the following steps:

[0041] Cut the silica gel sheet with a thickness of 1mm into a 5cm×5cm sheet, place it in acetone solution, a certain concentration of alkali solution, an acid solution, and deionized water for a certain period of time, and then take it out and dry it for later use; The treated silica gel sheet is placed on the processing table of the vacuum chamber of the plasma equipment, sealed, and evacuated to 2×10 -1 Pa; preheat for 15 minutes, feed 40.0 SCCM of helium to maintain the vacuum degree in the vacuum chamber at 30 Pa; turn on the plasma source, keep its power at 100W, and process for 10 minutes; Inject air to restore the air pressure in the treatment table to atmospheric pressure, take out the treated silica gel sheet; configure a certain concentration of silane coupling agent solution, put the treated silica...

Embodiment 3

[0044] The antibacterial medical polymer material is prepared by combining plasma-self-assembled monolayer film and electroless plating, including the following steps:

[0045] Cut the PVC material with a thickness of 1mm into 2.5cm×2.5cm thin slices, place them in acetone solution, a certain concentration of alkali solution, acid solution, and deionized water for a certain period of time, and then take them out and dry them for later use; Place the pretreated PVC on the processing table of the vacuum chamber of the plasma equipment, seal it, and evacuate it to 6×10 0 Pa; preheating for 10 minutes, injecting 20.0 SCCM of helium, and finally maintaining the vacuum degree in the vacuum chamber at 30 Pa; turn on the plasma source, keep its power at 50W, and process for 20 minutes; after the treatment, turn off the power of the processing table, Introduce air to restore the air pressure in the treatment table to atmospheric pressure; take out the treated silica gel sheet; configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com