Anti-static hardened film

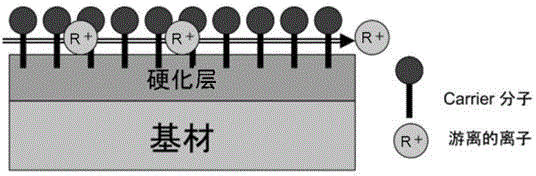

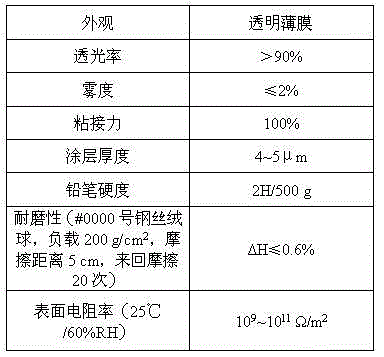

An antistatic and thin film technology, applied in the field of materials, can solve the problems of not having high hardness and wear resistance, light transmittance not up to the standard of optical grade film, easy to fog, etc., to achieve high light transmittance, no whitening , the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

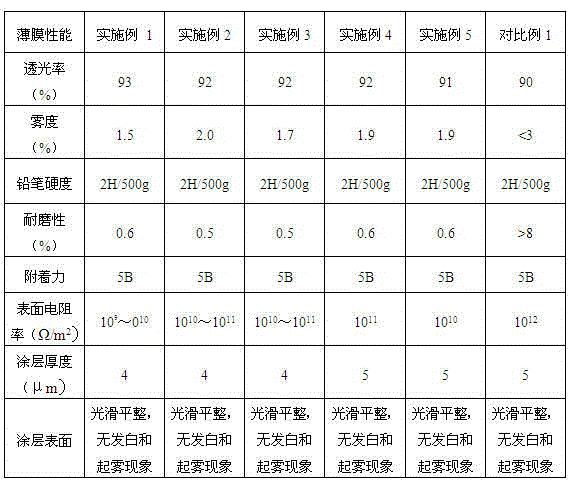

Embodiment 1

[0039]20g of hexafunctional aliphatic urethane acrylate (produced by Sartomer, USA, CN968), 5g of ethoxylated pentaerythritol tetraacrylate (produced by Changxing Chemical Materials Co., Ltd., EM2411), 10g of organic surfactant antistatic agent SN (Shanghai Tiantan Auxiliary Co., Ltd.), 1g benzophenone (Changzhou Huatai Chemical Co., Ltd.) and 0.5g coating additive BYK-302 (German BYK Chemical Co., Ltd.) added 63.5g n-butanol (Shanghai joint test Chemical Reagent Co., Ltd.), stir and mix evenly; use a 12 μm wire bar coater to coat the above mixture on one side of a PET film substrate (produced by Korea SKC Film Co., Ltd.), and dry it in a dryer at 80 ° C. Dry in medium temperature for 1min, and then cured by ultraviolet light (the irradiation light of ultraviolet light is 600 mj / cm 2 ), to obtain the finished antistatic hardened film. According to the above method, the performance test of the finished product is carried out, and the test results are shown in Table 2.

Embodiment 2

[0041] 20g of difunctional polyurethane acrylate (produced by Sartomer, USA, CN980), 6g of dipentaerythritol hexaacrylate (produced by Changxing Chemical Materials Co., Ltd., EM267), 20g of organic surfactant-type antistatic agent pur 200 (Shanghai Solon Industry Co., Ltd.), 3.6g of acrylated benzophenone (produced by Changzhou Huatai Chemical Co., Ltd.) and 0.4g of coating additive BYK-358N (produced by German BYK Chemical Co., Ltd.) added 50g of isopropanol (Shanghai United Test Chemical Reagent Co., Ltd.), stir and mix evenly; use a 12 μm wire bar coater to coat the above mixture on one side of a PET film substrate (produced by Korea SKC Film Co., Ltd.), and dry it at 80 ° C Dry in the machine for 1min, and then cured by ultraviolet light (the irradiation light of ultraviolet light is 600 mj / cm 2 ), to obtain the finished antistatic hardened film. According to the above method, the performance test of the finished product is carried out, and the test results are shown in T...

Embodiment 3

[0043] 20g of difunctional aliphatic urethane acrylate (produced by Sartomer, USA, CN980), 7.5g of pentaerythritol triacrylate (produced by Changxing Chemical Materials Co., Ltd., EM235), 4g of organic surfactant antistatic agent JP-518- 0 (produced by Chengbei Chemical Co., Ltd.), 1.2g 1-hydroxycyclohexyl phenyl ketone (produced by Changzhou Huatai Chemical Co., Ltd.) and 0.3g coating additive BYK-373 (produced by German BYK Chemical Co., Ltd.) add 67g propylene glycol Dimethyl ether (produced by Shanghai Lianshi Chemical Reagent Co., Ltd.), stir and mix evenly; use a 12 μm wire bar coater to coat the above mixture on one surface of a PC film substrate (produced by Korea SKC Film Co., Ltd.), and Dry in a dryer at 80°C for 1 min, and then cure with UV light (the irradiation brightness of UV light is 600 mj / cm 2 ), to obtain the finished antistatic hardened film. According to the above method, the performance test of the finished product is carried out, and the test results ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com