Method for processing papermaking wastewater and producing microbial oil, and its special bacterial strain

A technology of papermaking wastewater and microbial strains, applied in the method and its special strains, in the field of treating papermaking wastewater and producing microbial oil, can solve the problems that raw materials cannot meet the needs, the quality of different sources is difficult to control, and there are potential safety hazards, etc., so as to reduce pollution Emission problems, realization of resource utilization, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, preparation and identification of Rhodococcus sp. LDS5

[0045] Rhodococcus sp. (Rhodococcus sp.) RHA1 (on December 8, 2010 was preserved in the General Microbiology Center (CGMCC) of the China Committee for the Collection of Microbial Cultures, and its address is No. 3, No. 1, Beichen West Road, Chaoyang District, Beijing, the People's Republic of China, The Institute of Microbiology, Chinese Academy of Sciences, classified as Rhodococcus sp., and the registration number of the collection center: CGMCC No. 4423) knocked out the LDS5 gene to obtain Rhodococcus sp. (Rhodococcus sp.) LDS5. Rhodococcus sp. LDS5 was deposited on April 12, 2011 in the General Microbiology Center of the China Committee for the Collection of Microbial Cultures, and the registration number of the collection center is: CGMCC No.4762.

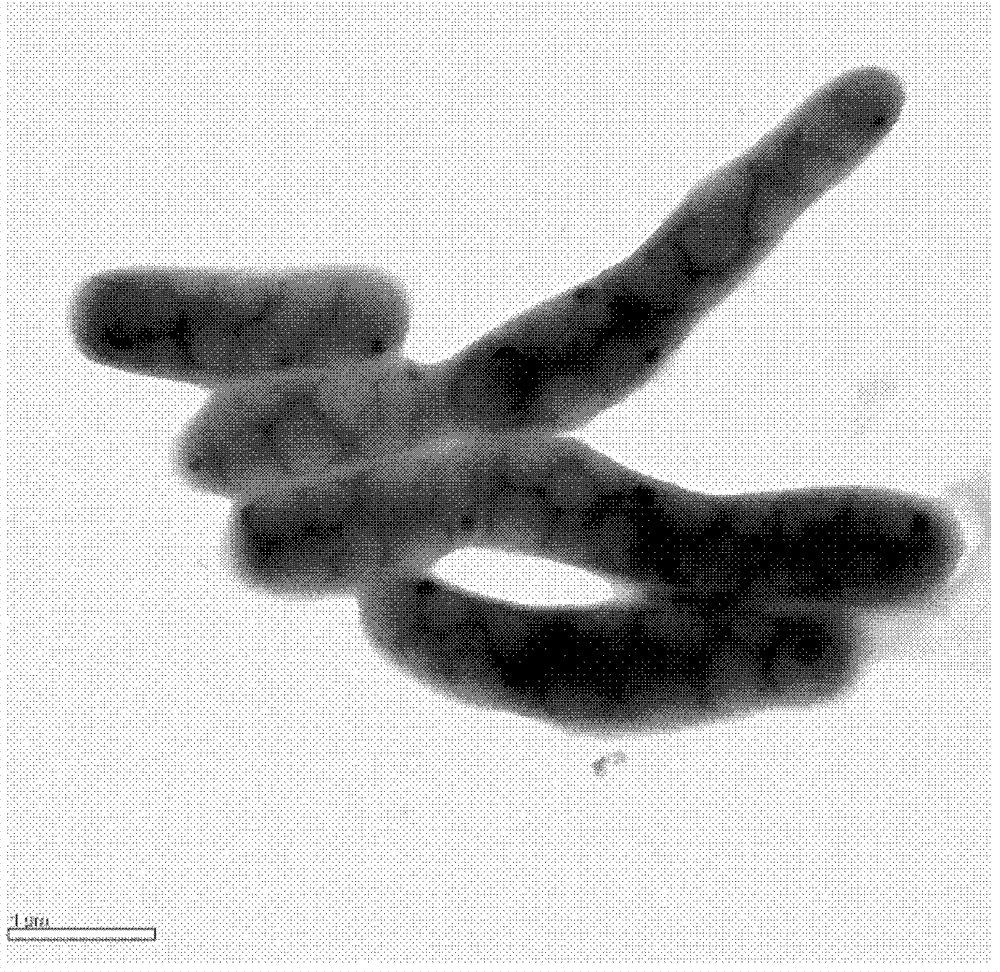

[0046] Rhodococcus sp. LDS5CGMCC No.4762 rod-shaped bacteria ( figure 1 ), do not form conidia or endospores. The colonies are pale yellow opaque,...

Embodiment 2

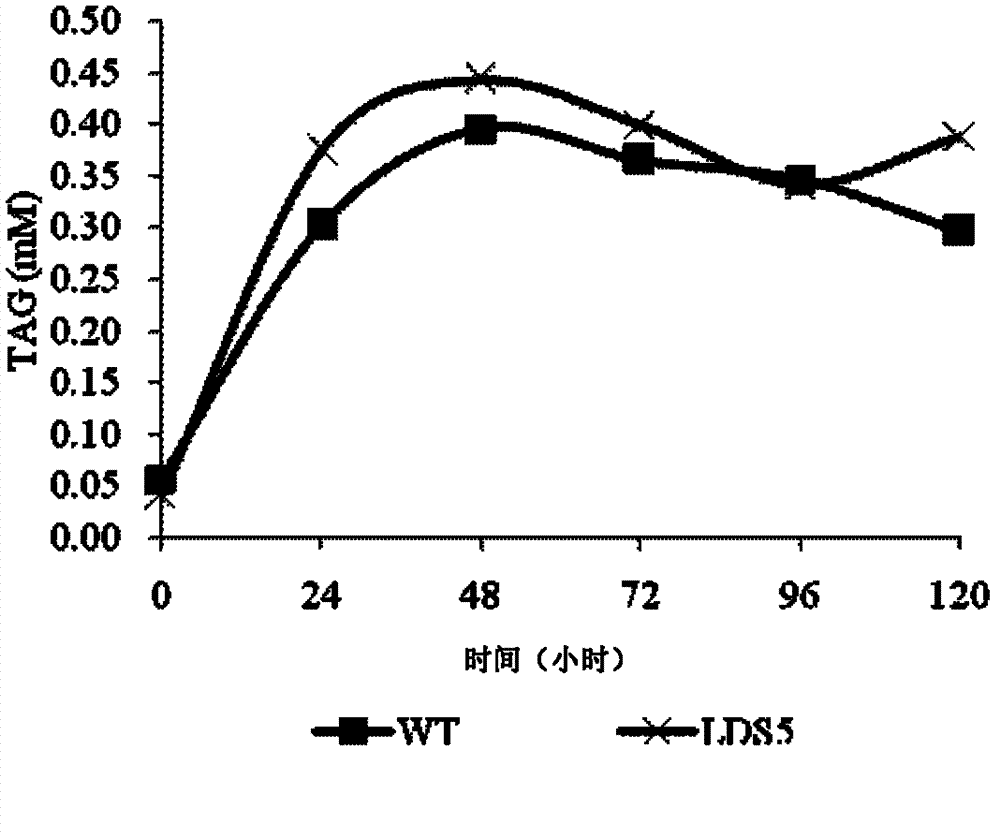

[0047] Example 2. A method for producing triglycerides by cultivating Rhodococcus sp. LDS5CGMCC No.4762 in papermaking wastewater.

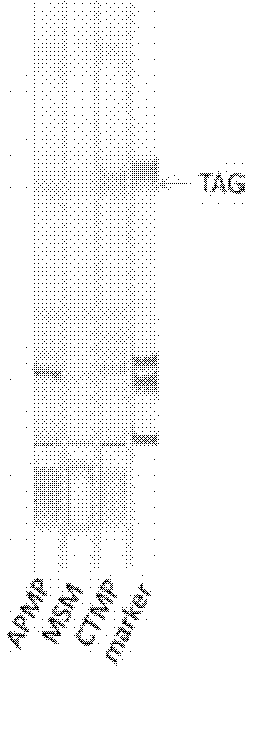

[0048] 1. Cultivate triglyceride detection in different wastewater

[0049] In order to find low-cost culture conditions, which are beneficial to large-scale culture. Low nitrogen and high carbon have become the main conditions for finding low-cost cultivation. Pulping and papermaking wastewater contains a large amount of organic matter, and it is rich in carbon sources and low in nitrogen. Using wastewater to cultivate strains, if they can grow, can not only obtain the supply of biodiesel raw materials, but also may promote the development of wastewater treatment industry. Therefore, this experiment selects the seriously polluted pulping wastewater CTMP wastewater and APMP wastewater in the paper industry, and checks the oil production of bacteria. The experimental steps are as follows:

[0050] Bacterial culture: Cultivate Rhodococcus sp. LD...

Embodiment 3

[0057] Embodiment 3, use Rhodococcus (Rhodococcus sp.) LDS5CGMCC No.4762 to treat papermaking wastewater

[0058] Bacteria with concentration gradient and time gradient are cultivated, and some wastewater indicators are detected for these bacteria. The cultivation method is as follows:

[0059] Concentration gradient: single clones of Rhodococcus sp. LDS5CGMCC No.4762 and Rhodococcus sp. RHA1CGMCC No.4423 were respectively inserted into 300ml NB medium and cultured at 30°C for 36h. Take 50ml, 20ml, and 10ml of 5000g culture solution, centrifuge at 4°C for 10 minutes, discard the supernatant, and transfer the centrifuged bacteria to 100ml of CTMP waste water (COD Cr 10053mg / L, BOD 5 9210mg / L), that is, the transfer concentrations were 1:2, 1:5, and 1:10, respectively. At the same time, 100ml of the same batch of CTMP wastewater was taken as a control. 30°C, 200 rpm shaking culture for 48 hours, centrifuge the liquid at 4000g, 4°C for 10 minutes, take the supernatant to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com