High temperature resistant metal connecting member, its preparation method, and solid oxide fuel cell stack

A technology of metal connectors and solid oxides, applied in the field of solid oxide fuel cells, can solve the problem of affecting the output performance and service life of solid oxide fuel cell stacks, low bonding force between perovskite coatings and metal connector surfaces, Affect the use of metal connectors and other issues, achieve the effect of tight interface, not easy to oxidize at high temperature, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also provides a preparation method for the above-mentioned high temperature resistant metal connector, comprising the following steps:

[0053] Spraying alloy powder on the surface of the metal connector substrate by plasma spraying, forming an alloy powder layer on the metal connector substrate;

[0054] The plasma spraying method is used to spray perovskite powder on the surface of the alloy powder layer to form a perovskite coating on the alloy powder layer.

[0055] Firstly, the alloy powder is sprayed on the surface of the base of the metal connector by using a plasma spraying method, and an alloy powder layer is formed on the base of the metal connector. Before spraying, first dry the alloy powder and preheat the base of the metal connector. The preheating method is preferably an empty spray gun or an oven preheating method. The preheating temperature is preferably 50 °C to 250°C, more preferably 100°C to 200°C.

[0056] Before preheating t...

Embodiment 1

[0085] Use a SUS430 metal connector with a thickness of 2mm as the base of the metal connector, rinse the base of the metal connector with deionized water, and fix it firmly on a flat base after drying; place the base of the metal connector at 100°C Preheating; the Ni-Cr alloy powder purchased from Chengdu Daguang Thermal Spraying Material Co., Ltd., the model is DG.Cr50, and the particle size is 0.01mm ~ 0.15mm is dried and sent to the plasma spraying machine. Spray coating on the preheated metal connector substrate to obtain a 1mm thick alloy powder coating;

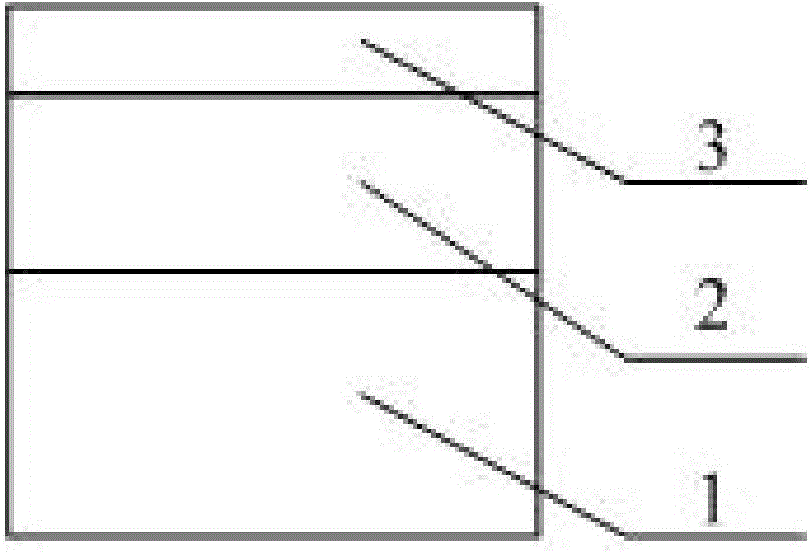

[0086] The LSM powder purchased from the Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, with a particle size of 0.01 mm to 0.15 mm was dried and sent to a plasma spraying machine, and the alloy powder coating was sprayed under the protection of nitrogen. A 1mm-thick perovskite coating is formed on the surface of the powder coating to obtain a metal connector with a structure of m...

Embodiment 2

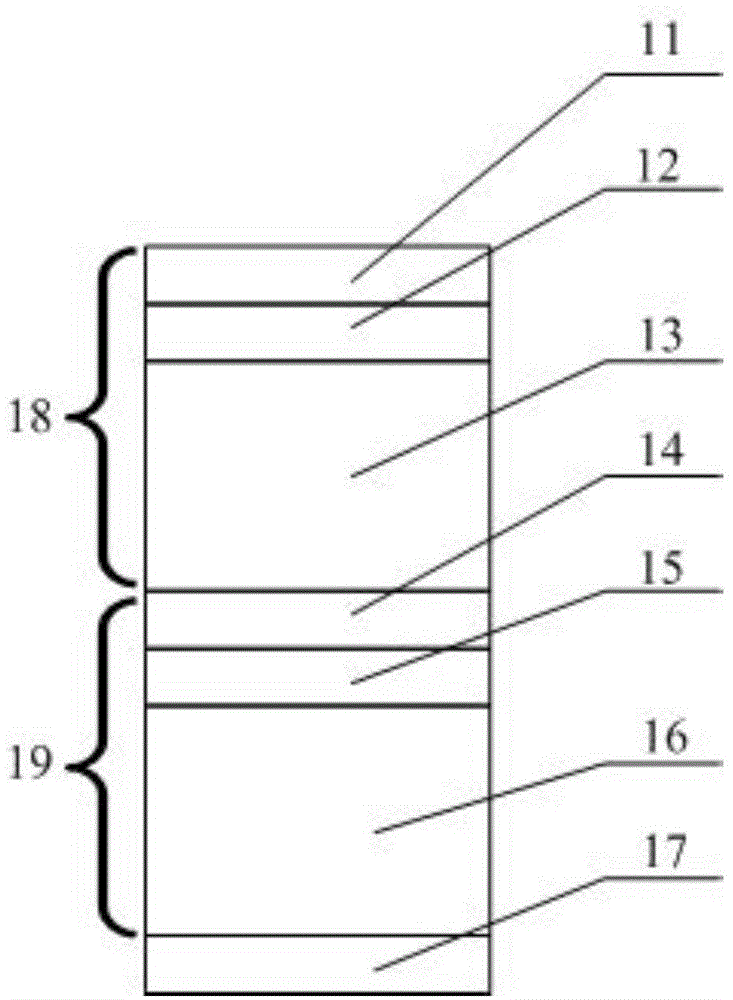

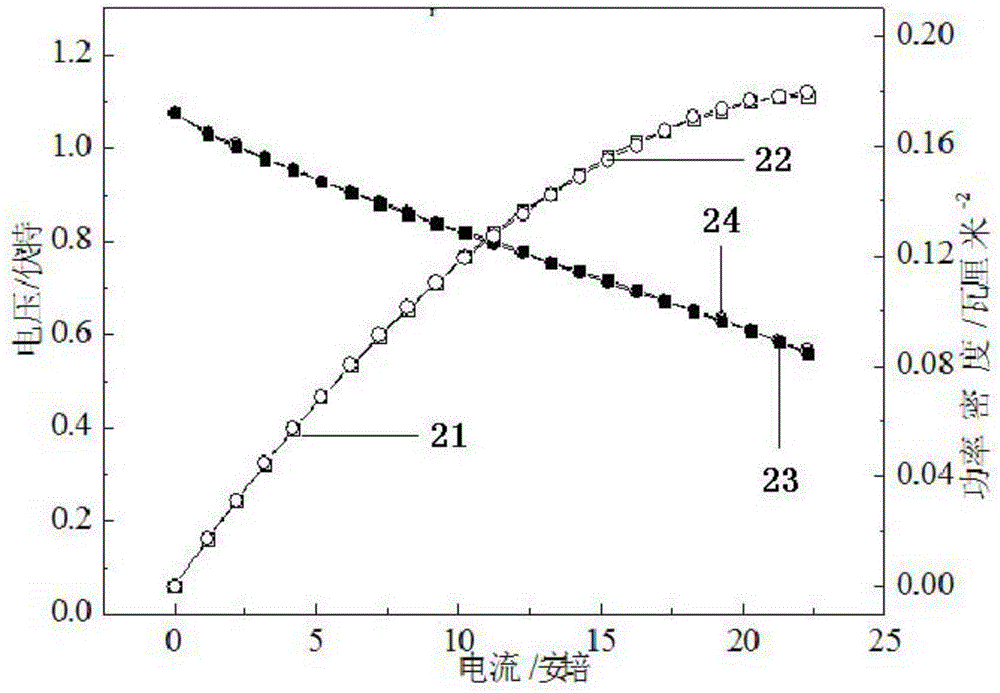

[0088] Two current collectors, two anode-supported Ni-YSZ / YSZ / LSM single cells with production batch numbers D110113-1 and D110218-4 developed by Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, and two 2mm-thick SUS430 metal connectors and the metal connectors prepared in Example 1 are raw materials, according to figure 2 The structure shown is assembled to obtain a two-unit fuel cell stack; figure 2 Schematic diagram of the structure of the solid oxide fuel cell stack prepared in Example 2 of the present invention, where 11 is the metal connector prepared in Example 1, 12 is the first current collector, and 13 is the single cell with the production batch number D110113-1 , 14 is the first SUS430 metal connector, 15 is the second current collector, 16 is the single battery with the production batch number D110218-4, 17 is the second SUS430 metal connector, 18 is the single battery 13, the current collector 12 and The metal connector 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com