Preparation method of nanometer Zn/Al ZSM-5 molecular sieve

A molecular sieve and nanotechnology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of serious pollution, high cost, high toxicity, etc., achieve good nano characteristics and reduce production costs , to solve the effect of high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

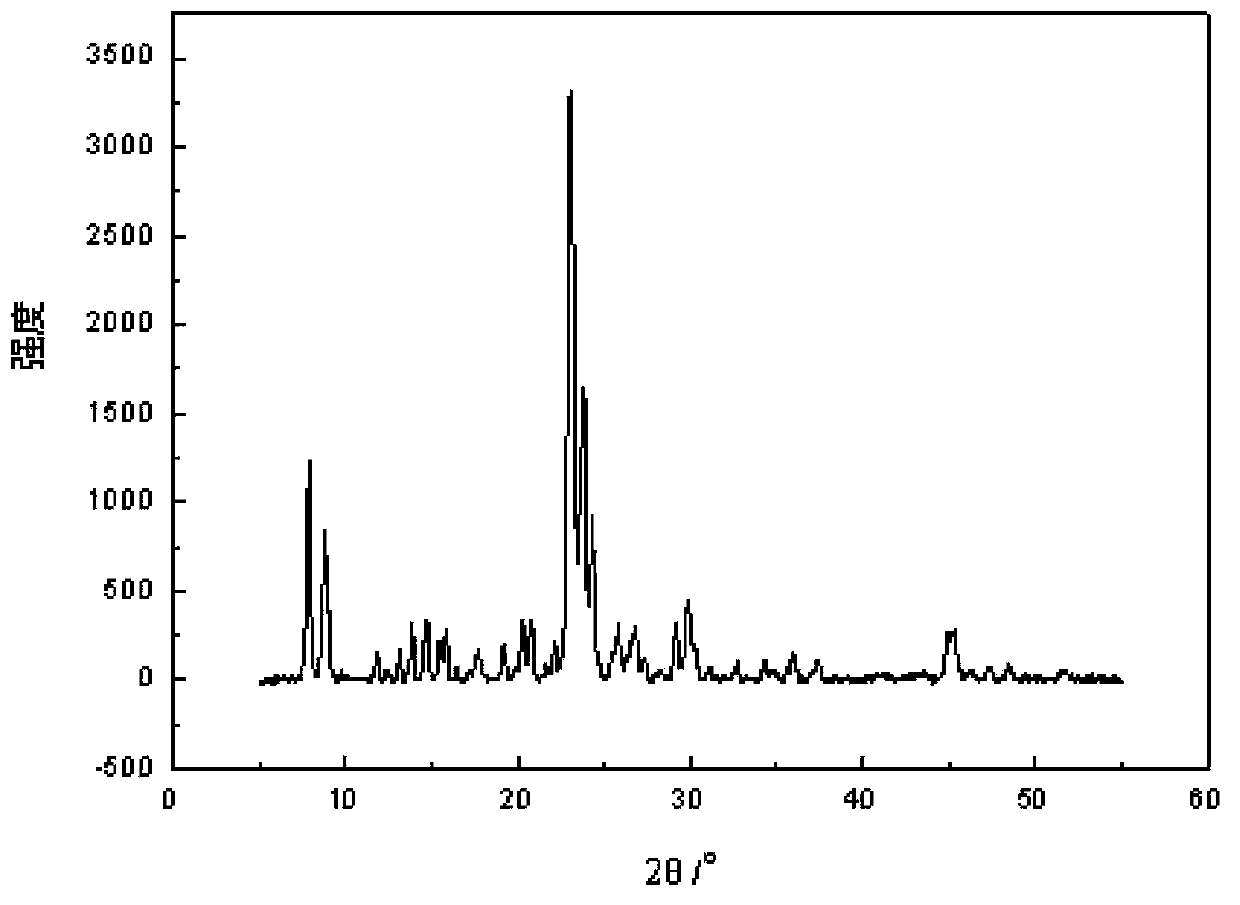

[0021] Specific embodiment one: the preparation method of a kind of nanometer Zn / AlZSM-5 molecular sieve of the present embodiment is realized through the following steps:

[0022] 1. Preparation of precrystallized seed crystals: a. Weigh 1 part of aluminum isopropoxide, 24 to 115 parts of tetrapropylammonium hydroxide aqueous solution, 21 to 83 parts of ethyl orthosilicate and 1.6~5.7 parts of deionized water; Wherein, the mass percentage concentration of tetrapropyl ammonium hydroxide in tetrapropyl ammonium hydroxide aqueous solution is 30%; b, aluminum isopropoxide and tetrapropyl ammonium hydroxide are added to deionized water In deionized water, stir for 10 to 30 minutes at a stirring speed of 300 to 500 r / min; c. Add ethyl orthosilicate dropwise to the liquid obtained in step b at the same stirring speed, and all ethyl orthosilicate Continue to stir for 2 hours after the dropwise addition to obtain a mixed gel; d. Place the mixed gel obtained in step c in a stainless st...

specific Embodiment approach 2

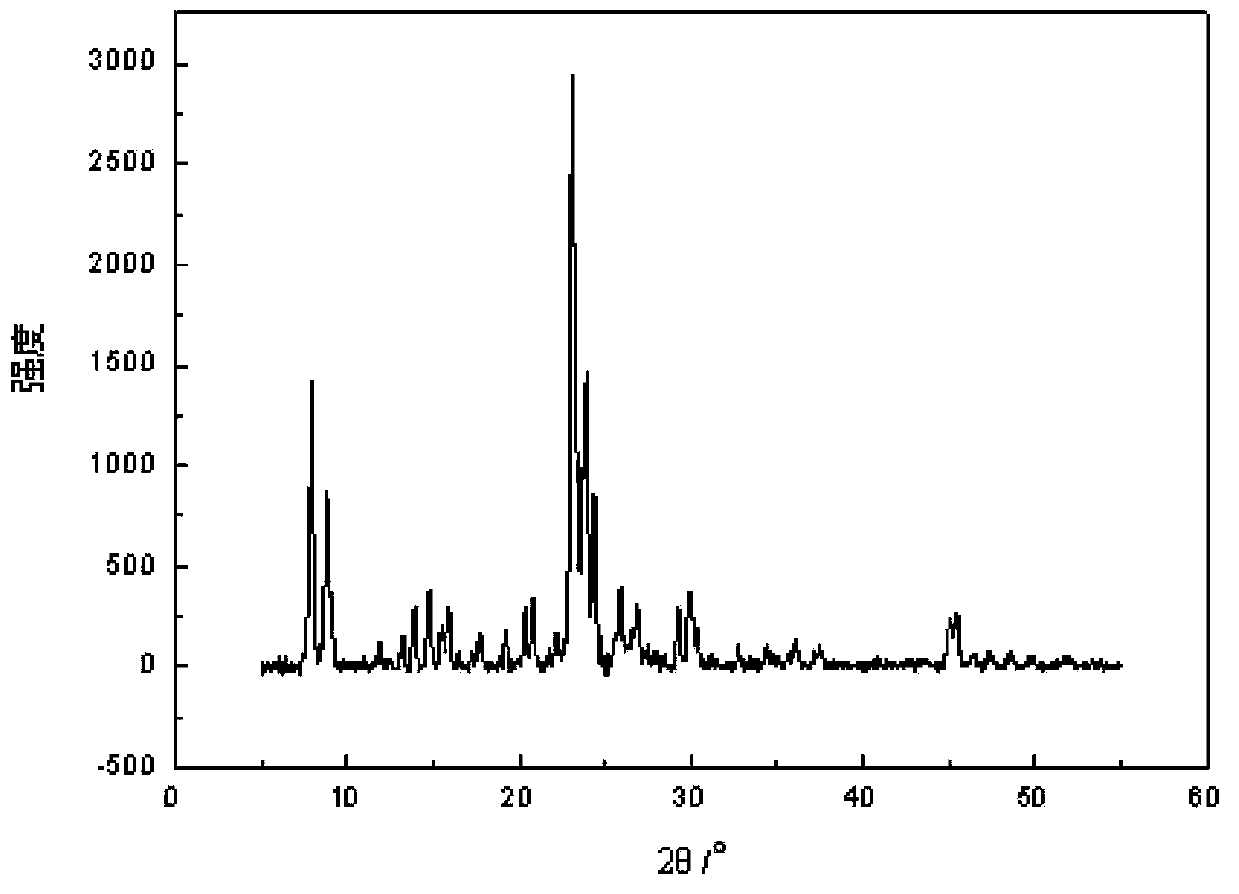

[0029] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the crystallization temperature in step d of step 2 is 135-155° C., and the crystallization time is 10-15 hours. Other steps and parameters are the same as those of specific embodiment 1. .

specific Embodiment approach 3

[0030] Specific embodiment 3: This embodiment differs from specific embodiment 1 or 2 in that: the crystallization temperature in step d of step 2 is 150°C, the crystallization time is 12h, and other steps and parameters are the same as specific embodiment 1 or 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com