Reclaimed polypropylene (PP)-based wood-plastic composite material and preparation method thereof

A wood-plastic composite material and premix technology, which is applied in the field of wood-plastic composite materials to achieve the effects of easy control, good wood imitation effect and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

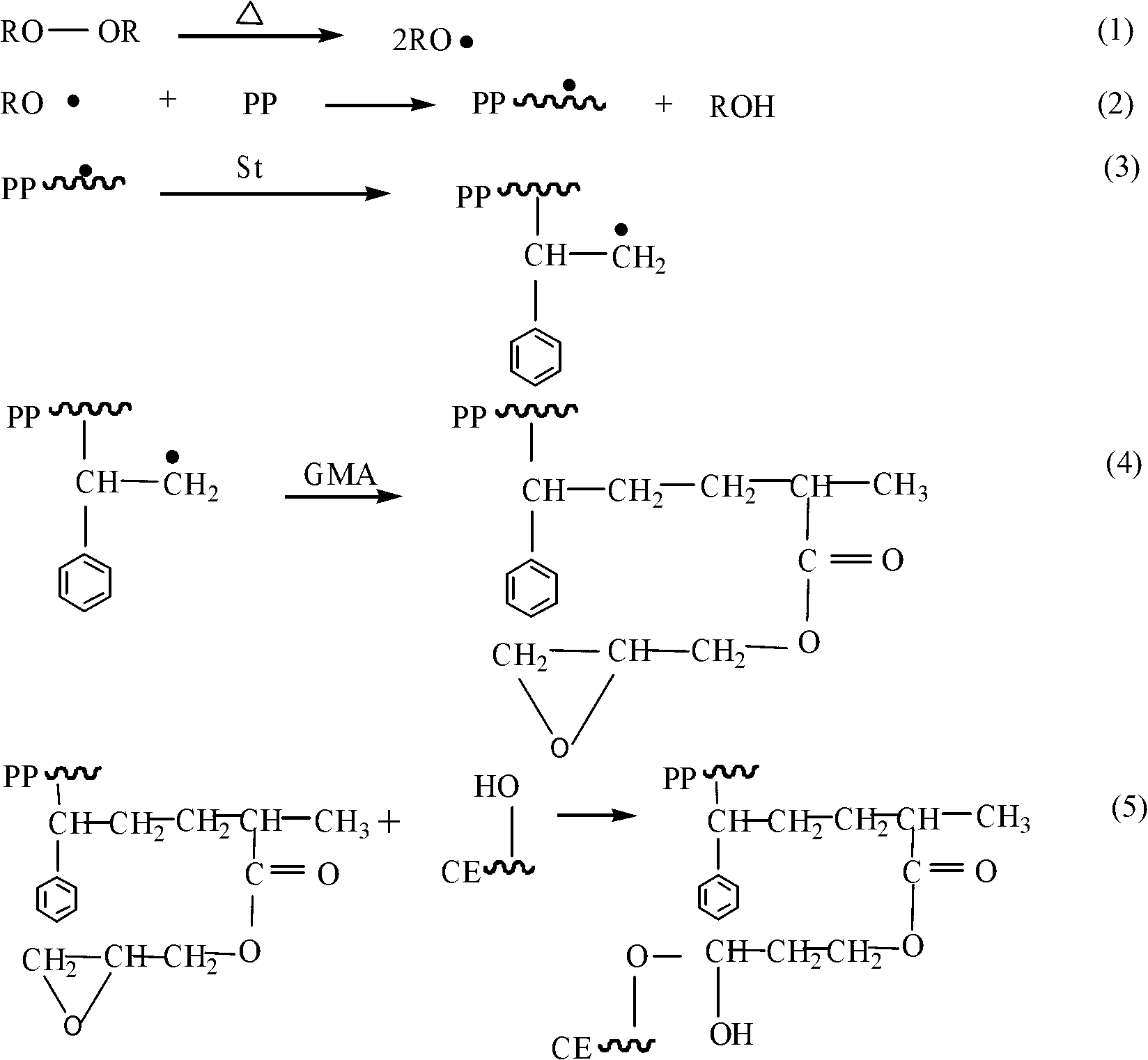

Method used

Image

Examples

Embodiment 1

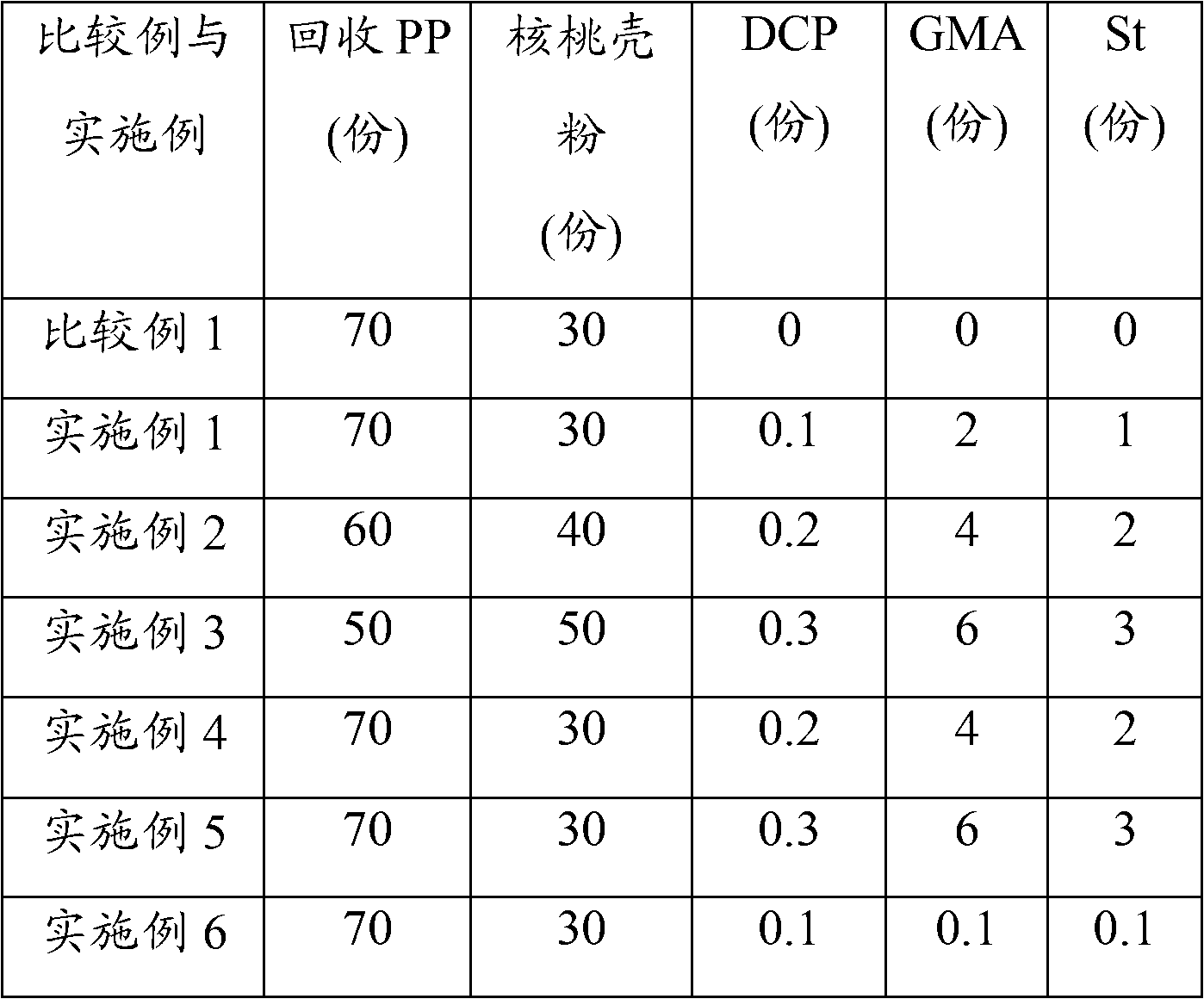

[0055] A recycled PP-based wood-plastic composite material, which is made of the following raw materials in parts by weight: 70 parts of recycled PP; 30 parts of walnut shell powder, the sum of the weight parts of recycled PP and walnut shell powder is 100; dicumyl peroxide 0.1 part; 2 parts of glycidyl methacrylate; 1 part of styrene.

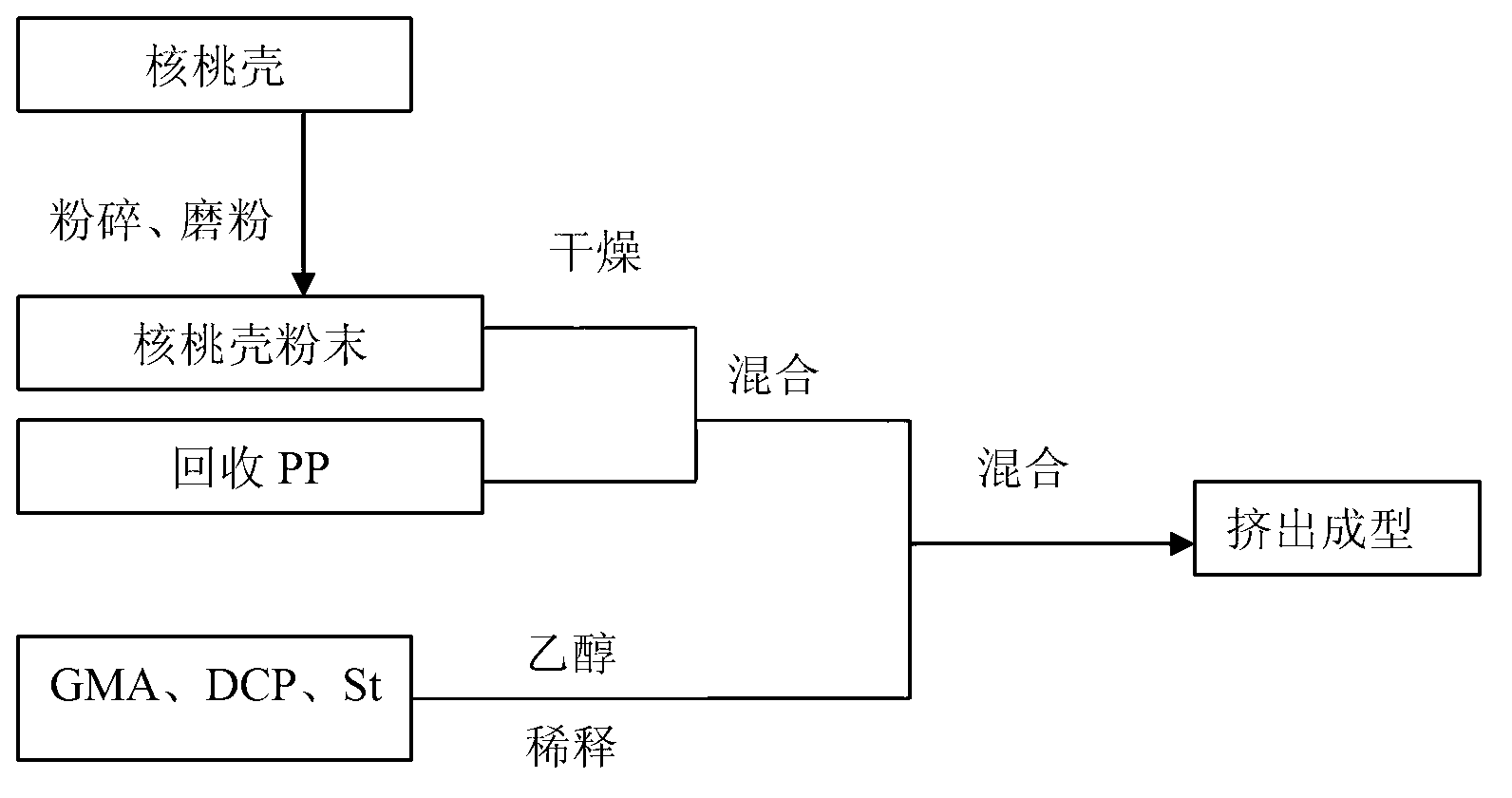

[0056] A preparation method for reclaiming PP-based wood-plastic composite material, the method comprising the following steps:

[0057] (1), walnut shells are pulverized, ground into powder, the particle size is 150 mesh, placed in a vacuum oven for drying treatment, the temperature of the oven is controlled at 120 ° C, dried for 6 hours, and then cooled to room temperature;

[0058] (2), dicumyl peroxide, glycidyl methacrylate, and styrene are dissolved in diluent ethanol, and placed for subsequent use;

[0059] (3) Mix the dried walnut shell powder and recycled PP evenly in proportion, pour the mixed solution in step (2) into the mixture o...

Embodiment 2

[0064] A recycled PP-based wood-plastic composite material is prepared from the following raw materials in parts by weight: 60 parts of recycled PP; 40 parts of walnut shell powder, the sum of the weight parts of recycled PP and walnut shell powder is 100; 0.2 parts of dicumyl peroxide parts; 4 parts of glycidyl methacrylate; 2 parts of styrene.

[0065] A preparation method for reclaiming PP-based wood-plastic composite material, the method comprising the following steps:

[0066] (1), walnut shells are pulverized, ground into powder, the particle size is 150 mesh, placed in a vacuum oven for drying treatment, the temperature of the oven is controlled at 120 ° C, dried for 6 hours, and then cooled to room temperature;

[0067] (2), dicumyl peroxide, glycidyl methacrylate, and styrene are dissolved in diluent ethanol, and placed for subsequent use;

[0068] (3) Mix the dried walnut shell powder and recovered PP evenly in proportion, pour the mixed solution in step (2) into th...

Embodiment 3

[0073] A recycled PP-based wood-plastic composite material is prepared from the following raw materials in parts by weight: 50 parts of recycled PP; 50 parts of walnut shell powder, the sum of the weight parts of recycled PP and walnut shell powder is 100; parts; 6 parts of glycidyl methacrylate; 3 parts of styrene.

[0074] A preparation method for reclaiming PP-based wood-plastic composite material, the method comprising the following steps:

[0075] (1), walnut shells are pulverized, ground into powder, the particle size is 150 mesh, placed in a vacuum oven for drying treatment, the temperature of the oven is controlled at 120 ° C, dried for 6 hours, and then cooled to room temperature;

[0076] (2), dicumyl peroxide, glycidyl methacrylate, and styrene are dissolved in diluent ethanol, and placed for subsequent use;

[0077] (3) Mix the dried walnut shell powder and recovered PP evenly in proportion, pour the mixed solution in step (2) into the walnut shell powder and reco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com