Carbon nanotube/benzoxazine/bimaleimide composite material and preparation method thereof

A technology of bismaleimide and carbon nanotubes, applied in the field of carbon nanotube/benzoxazine/bismaleimide composite materials and their preparation, to achieve good mechanical properties, improve mechanical properties and friction properties , Enhance the effect of interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

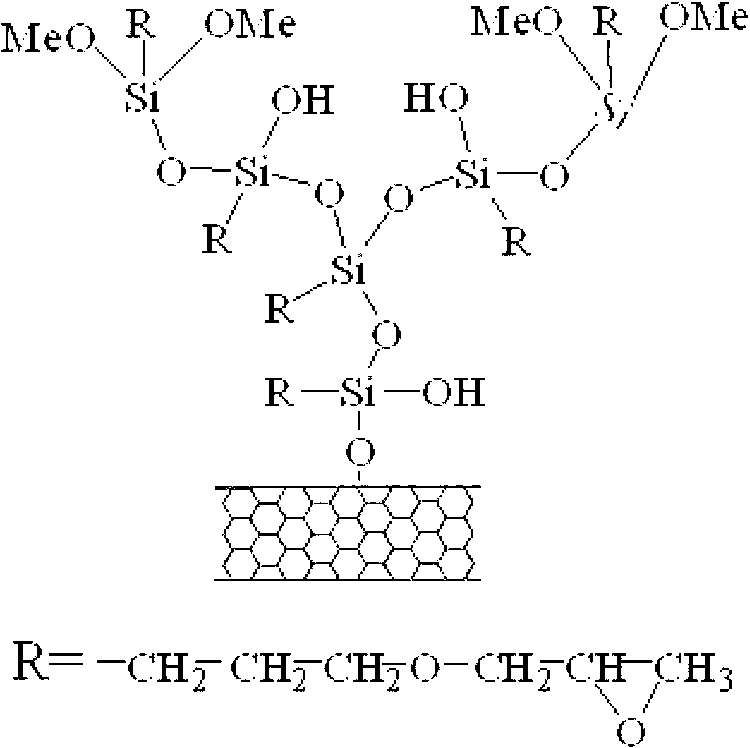

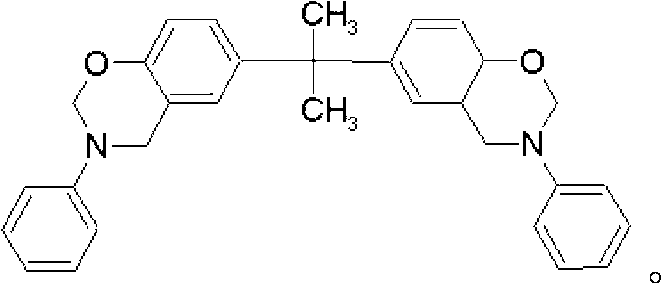

[0034] (1) Add 0.1~10 parts of carbon nanotubes to 1~100 parts of KH-560 tetrahydrofuran solution, ultrasonically disperse for 0.5h, add dropwise 1~50mL of HCl aqueous solution with a concentration of 1mol / L, and then in 50~80 After stirring for 4-7 hours at ℃, hyperbranched polysiloxane-modified carbon nanotubes were obtained;

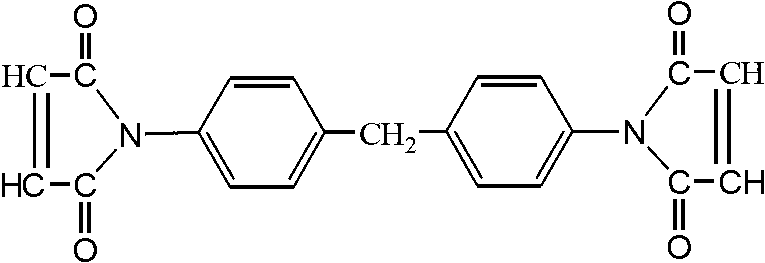

[0035] (2) Mix 100 parts of benzoxazine resin and 5 parts of bismaleimide resin prepolymer, and after melting completely at 120-160°C, add 0.1 part of hyperbranched polysiloxane-modified carbon nanotubes , pre-polymerized for 15~60min, then poured into a preheated mold, put it into a vacuum box at 150°C, vacuumed to remove air bubbles, took out the mold, put it into a blast drying oven for stage-by-stage temperature curing, and the curing process is 150°C / 2h, 170°C / 2h, 180°C / 4h, then natural cooling, demoulding, and post-treatment at 200°C for 2h to obtain carbon nanotube / benzoxazine / bismaleimide composite material.

Embodiment 2

[0037] (1) The preparation method of hyperbranched polysiloxane modified carbon nanotubes is the same as that of Example 1;

[0038] (2) Mix 100 parts of benzoxazine resin and 10 parts of bismaleimide resin prepolymer, and after melting completely at 120-160°C, add 1 part of hyperbranched polysiloxane-modified carbon nanotubes, Pre-polymerize for 15~60 minutes, then pour it into a preheated mold, put it into a vacuum box at 150°C, vacuumize to remove air bubbles, take out the mold, put it into a blast drying oven for stage-by-stage heating and curing, and the curing process is 150°C / 2h , 170°C / 2h, 180°C / 4h, then naturally cooled, after demoulding, and post-treatment at 200°C for 2h to obtain the carbon nanotube / benzoxazine / bismaleimide composite material.

Embodiment 3

[0040] (1) The preparation method of hyperbranched polysiloxane modified carbon nanotubes is the same as that of Example 1;

[0041](2) Mix 100 parts of benzoxazine resin and 15 parts of bismaleimide resin prepolymer, and after melting completely at 120-160°C, add 2 parts of hyperbranched polysiloxane-modified carbon nanotubes, Pre-polymerize for 15~60 minutes, then pour it into a preheated mold, put it into a vacuum box at 150°C, vacuumize to remove air bubbles, take out the mold, put it into a blast drying oven for stage-by-stage heating and curing, and the curing process is 150°C / 2h , 170°C / 2h, 180°C / 4h, then naturally cooled, after demoulding, and post-treatment at 200°C for 2h to obtain the carbon nanotube / benzoxazine / bismaleimide composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com