Purifying method and purifying device for argon gas

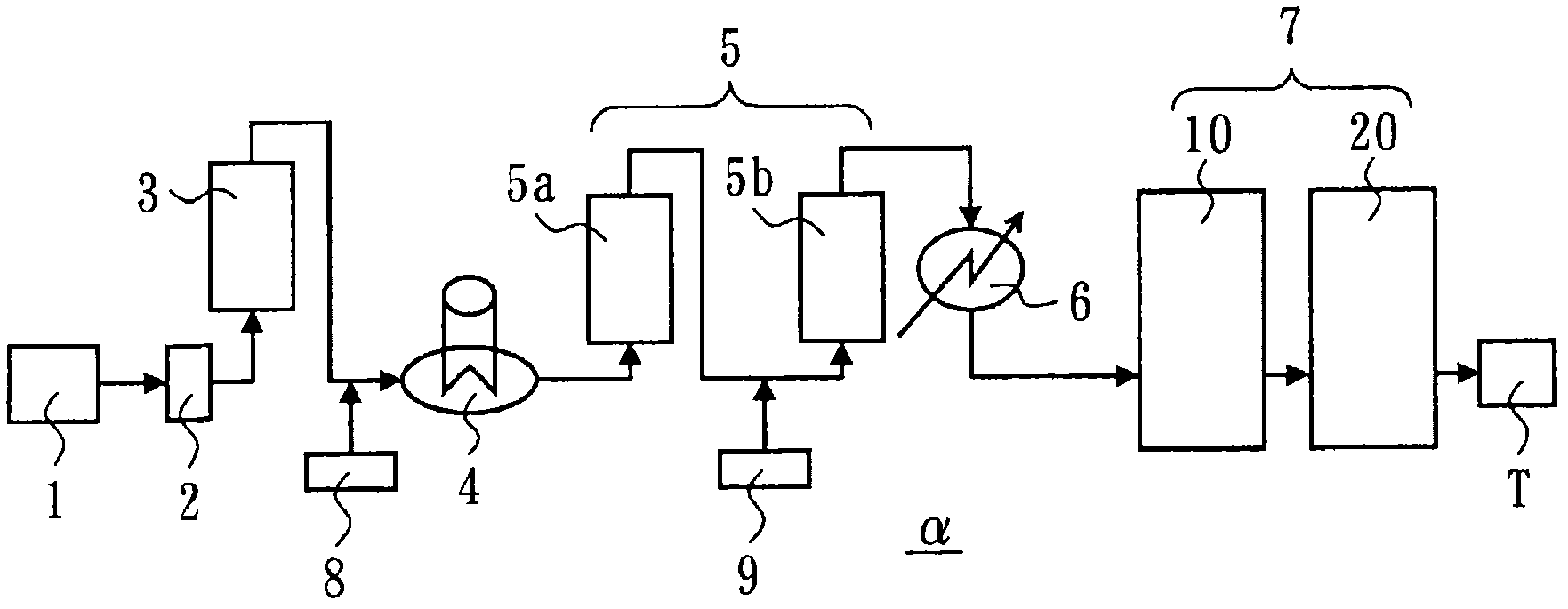

A purification method, argon technology, applied in separation methods, chemical instruments and methods, inert gas compounds, etc., can solve the problems of hydrogen residue, inability to argon purification, adsorption removal, etc., to reduce adsorption load, reduce purification load, The effect of lightening the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

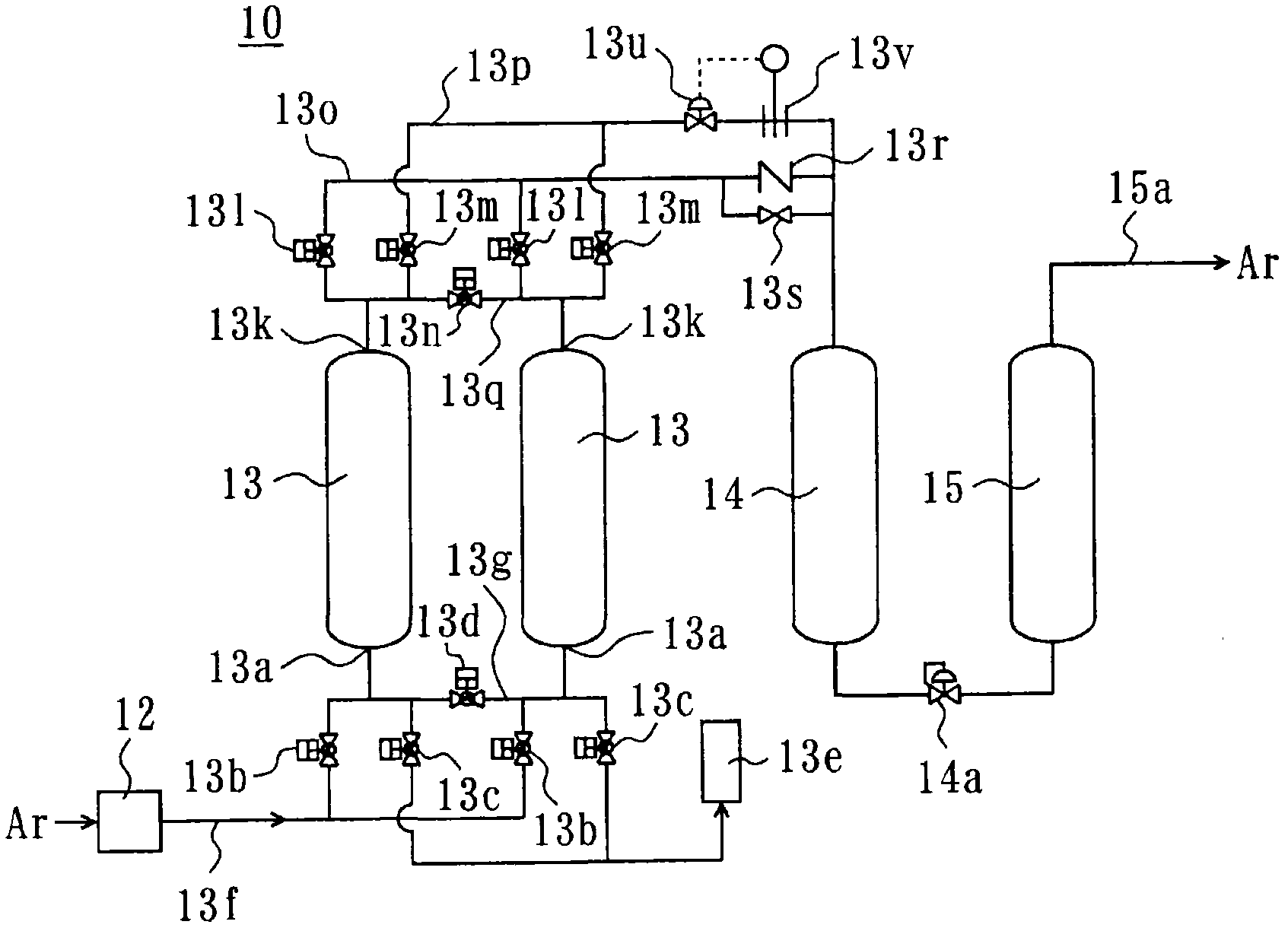

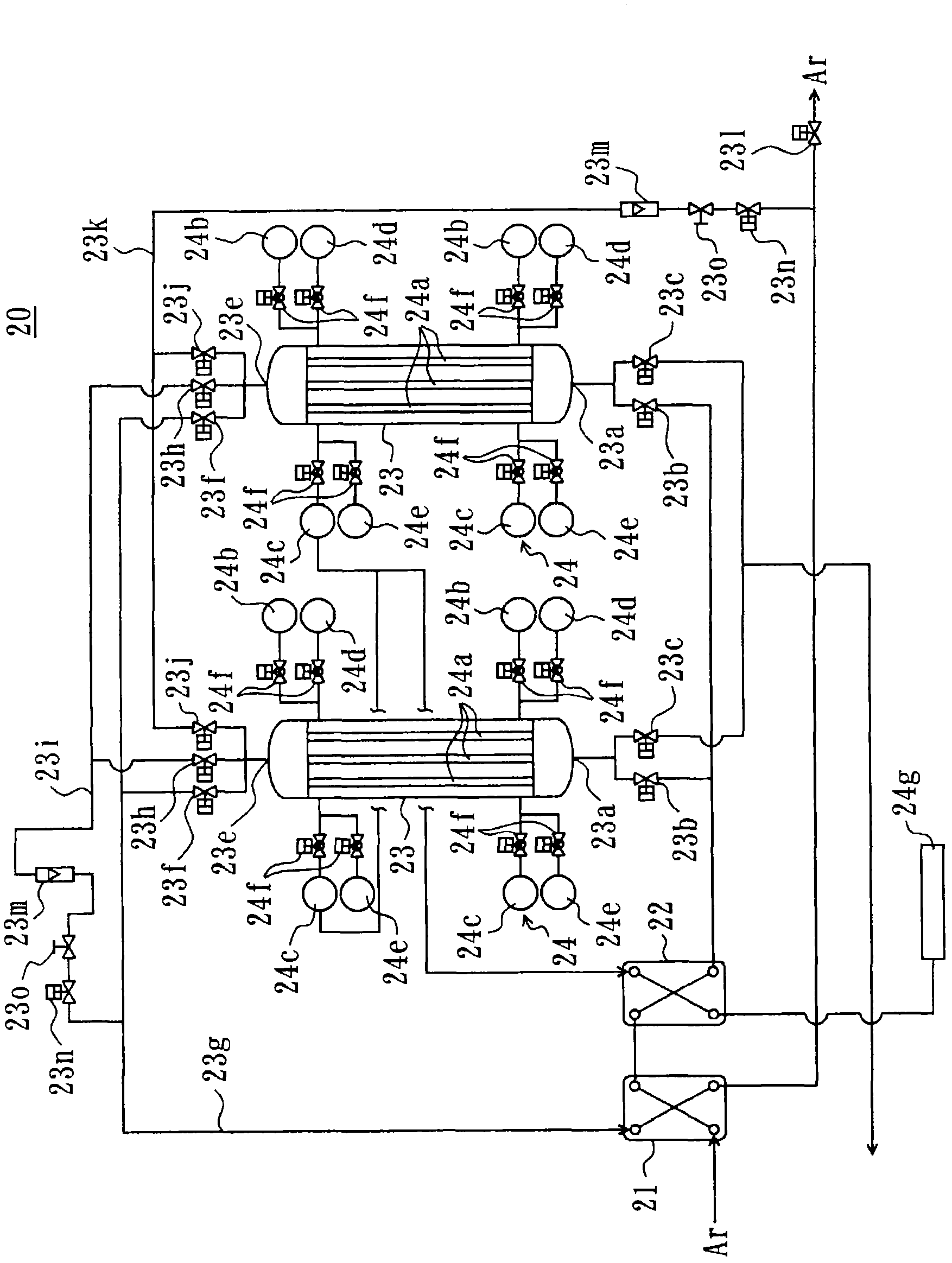

Embodiment 1

[0108] Purification of argon gas was performed using the purification apparatus α of the above-mentioned first embodiment. The argon gas before purification contains 300 mol ppm oxygen, 30 mol ppm hydrogen, 200 mol ppm carbon monoxide, 1200 mol ppm nitrogen, 10 mol ppm carbon dioxide, 10 mol ppm water, 10 mol ppm Methane as hydrocarbons, C2-C5 hydrocarbons at 20 mol ppm in terms of C1 hydrocarbons, 5 g / m 3 of oil. This argon is introduced into activated carbon adsorption tower 3 with the flow rate of 4.2L / min under the standard state. The activated carbon adsorption tower 3 is tubular with a nominal diameter of 32A, filled with 10 L of GX6 / 8 briquette manufactured by Nippon Environmental Chemicals Co., Ltd. Then, argon gas is introduced into the first reactor 5a. 50 mL of alumina-supported palladium catalyst (DASH-220D manufactured by N E Chem Kit Co., Ltd.) was filled in the first reactor 5 a, and the reaction conditions were set at a temperature of 350° C., atmospheric pr...

Embodiment 2

[0116] The oxygen concentration of the argon gas used for purification was 50 mol ppm, and the nitrogen concentration was 200 mol ppm, and oxygen was added to the argon gas from the oxygen supplier 8 at 1.1 ml / min before the first reactor 5a (so that the contained oxygen About 1.4 times the theoretical value required to react with hydrogen, carbon monoxide and hydrocarbons). Argon was purified under the same conditions as in Example 1 except that.

[0117] In this case, the impurity composition of the argon gas at the outlet of the activated carbon adsorption tower 3 and the outlet of the TSA unit 20 is as follows.

[0118] ·Activated carbon adsorption tower outlet

[0119] Hydrogen: 30 mole ppm, oxygen: 50 mole ppm, nitrogen: 200 mole ppm, carbon monoxide: 200 mole ppm, carbon dioxide: 10 mole ppm, water: 10 mole ppm, methane: 10 mole ppm, C2~C5 hydrocarbons: C1 hydrocarbons Converted to 15 mole ppm, oil content: not detected.

[0120] · TSA unit exit

[0121] Hydrogen: l...

Embodiment 3

[0123] The catalyst used in the second reactor 5b is palladium supported on alumina. Argon was purified under the same conditions as in Example 1 except that.

[0124] In this case, the impurity compositions of the argon gas at the outlet of the first reactor 5 a , the outlet of the second reactor 5 b , the outlet of the PSA unit 10 , and the outlet of the TSA unit 20 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com