Trichloroethane tail gas treatment device and method in sucralose production

A technology for trichloroethane and tail gas treatment, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problem of high cost of trichloroethane tail gas treatment, and reduce production labor intensity, cost, and energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

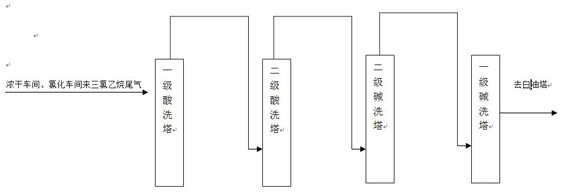

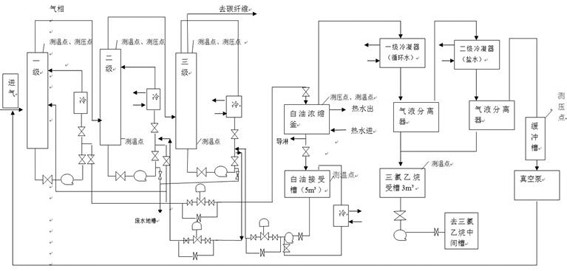

[0028] (1) The tail gas (trichloroethane gas, dimethylamine gas, DMF gas, sulfur dioxide gas, ammonia gas) from the thickening and drying section and the chlorination section is sent to the first-stage inch by the induced draft fan at a speed of 5000-8000m³ / h PTFE pickling tower, two-inch PTFE pickling tower, the absorption liquid is 20% dilute hydrochloric acid and 10% dilute hydrochloric acid respectively, to remove alkaline impurity gases such as dimethylamine and ammonia in the tail gas;

[0029] (2) The gas after the secondary pickling (trichloroethane gas, DMF gas, sulfur dioxide gas, hydrogen chloride gas) is sent to the first-level PP alkali washing tower and the first-level PP alkali washing tower at a rate of 5000-8000m³ / h Adsorb the acidic impurity gas sulfur dioxide in the tail gas and the residual acid gas in the pickling tower, and the absorption liquid is a sodium hydroxide solution with a concentration of 10%;

[0030] (3) The tail gas (trichloroethane gas, DMF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com