Method for preparing betaine hydrochloride

A betaine and hydrochloride technology, which is applied in the preparation of organic compounds, chemical instruments and methods, and cyanide reaction preparation, etc., can solve the problems that limit the development of betaine industrialization, the inability to treat high-salt wastewater, and the product yield. and quality impact, to achieve the effect of simple and sufficient product separation, quick and sufficient reaction, high economy and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

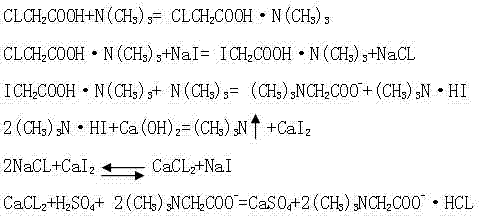

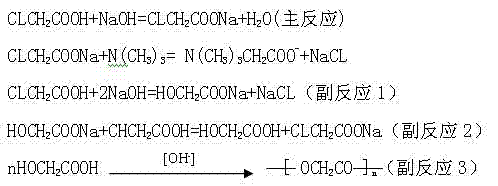

Method used

Image

Examples

Embodiment 1

[0017] Materials with the following weight proportions: trimethylamine (content ≥98%) 1000g, chloroacetic acid (content ≥98%) 670g, sodium iodide (content ≥98%) 11g, calcium oxide (content ≥95%) 200g, concentrated Sulfuric acid 370g.

[0018] The specific operation is as follows:

[0019] 670g of chloroacetic acid and 11g of iodine are made into a 30% aqueous solution containing chloroacetic acid, and 1000g of trimethylamine is made into a 40% aqueous solution, and are injected into the pipeline reactor in proportion to the room temperature through a peristaltic pump for reaction. The residence time of the material in the reactor is controlled at 1 hour. The material coming out of the reactor is subjected to gas-liquid separation, and the separated material liquid is put into a 2000ML reaction bottle, and 200g of calcium oxide is added in batches under stirring conditions, and the temperature is slowly raised to 65°C for 0.5 hours after the addition, and the escaped gas is co...

Embodiment 2

[0021] Materials with the following weight proportions: trimethylamine (content ≥98%) 1000g, chloroacetic acid (content ≥98%) 670g, sodium iodide (content ≥98%) 13g, calcium oxide (content ≥95%) 200g, concentrated Sulfuric acid 370g.

[0022] The specific operation is as follows:

[0023] 670g of chloroacetic acid and 13g of iodine are made into a 30% aqueous solution containing chloroacetic acid, and 1000g of trimethylamine is made into a 40% aqueous solution, and are injected into the pipeline reactor in proportion to the room temperature through a peristaltic pump for reaction. The residence time of the material in the reactor is controlled at 40 minutes. The material coming out of the reactor is subjected to gas-liquid separation, and the separated material liquid is put into a 2000ML reaction bottle, and 200g of calcium oxide is added in batches under stirring conditions, and the temperature is slowly raised to 65°C for 0.5 hours after the addition, and the escaped gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com