Pickle nutrient solution and pickle granule bag type fermentation method

A nutrient solution and kimchi technology, which is applied in acid preservation of fruits/vegetables, food preparation, food science, etc., can solve the problems of short shelf life, inconvenient consumption, and long fermentation cycle, so as to improve the content of nutrients and make eating kimchi easy , the effect of a reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A. After sorting and washing white radish, carrot and celery sticks, cut them into 1.5 to 2.5cm particles, soak them in food-grade hydrogen peroxide disinfectant for 8 minutes, then rinse them with clean water, and put them into sterilized containers. Strain the water out of the vegetable basket.

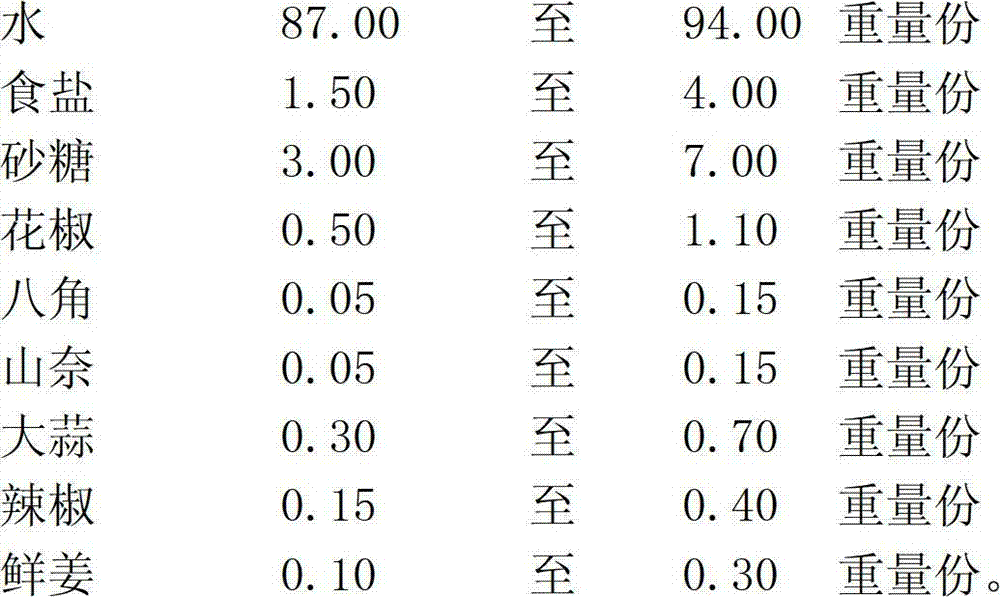

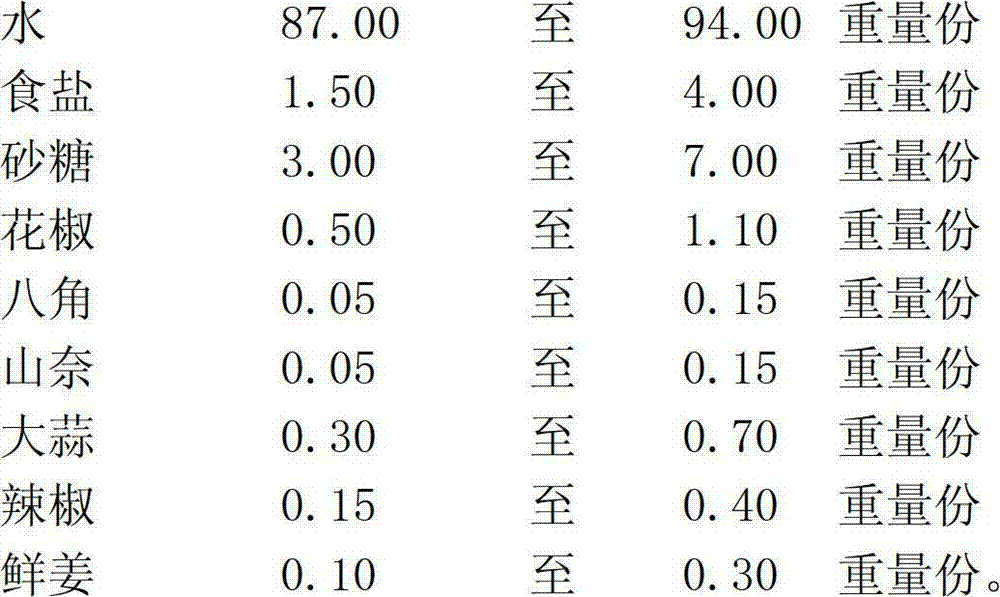

[0028] B. Preparation of nutrient solution: 90g of water, 3g of salt, 5g of sugar, 0.8g of Chinese prickly ash, 0.1g of star anise, 0.1g of kaempferia, 0.5g of garlic, 0.3g of pepper, and 0.2g of fresh ginger. After preparing the nutrient solution, boil it for 3 to 5 minutes, then cool it to 25°C, add 20g of lactic acid compound bacteria agent to 100kg of nutrient solution, and the lactic acid compound bacteria agent is composed of Lactobacillus plantarum 550 bacteria powder and Lactobacillus Brucella 225 bacteria powder according to the weight ratio 65~70:30~35 formulated lactic acid compound bacterial agent.

[0029] C. Put white radish, carrot and celery into bags, add 50...

Embodiment 2

[0032] A. Preparation of raw materials

[0033] After sorting and washing, white radish, carrot and celery stalks are cut into 1.5 to 2.5cm particles, soaked in food-grade hydrogen peroxide disinfectant for 5 to 10 minutes, then rinsed with clean water, and put into sterilized Strain the water out of the vegetable basket.

[0034] B. Preparation of nutrient solution

[0035] The formula of the nutrient solution is: water 94g, salt 4g, sugar 7g, Chinese prickly ash 1.1g, star anise 0.15g, kaempferen 0.15g, garlic 0.7g, pepper 0.4g, fresh ginger 0.3g. After preparing the nutrient solution, boil it for 3 to 5 minutes, then cool it to 28°C, add 15g of lactic acid compound bacteria agent to 100kg of nutrient solution, and the lactic acid compound bacteria agent is composed of Lactobacillus plantarum 550 bacteria powder and Lactobacillus Brucella 225 bacteria powder according to the weight ratio 65~70:30~35 formulated lactic acid compound bacterial agent.

[0036] C. Bagging

[...

Embodiment 3

[0041] A. Preparation of raw materials

[0042] After sorting and washing, white radish, carrot and celery stalks are cut into 1.5 to 2.5cm particles, soaked in food-grade hydrogen peroxide disinfectant for 5 to 10 minutes, then rinsed with clean water, and put into sterilized Strain the water out of the vegetable basket.

[0043] B. Preparation of nutrient solution

[0044] The formula of the nutrient solution is: 87g of water, 1.5g of salt, 3g of sugar, 0.5g of Chinese prickly ash, 0.05g of star anise, 0.05g of kaempferen, 0.3g of garlic, 0.15g of pepper, and 0.1g of fresh ginger. After preparing the nutrient solution, boil it for 3 to 5 minutes, then cool it to 20°C, add 25g of lactic acid compound bacteria agent to 100kg of nutrient solution, and the lactic acid compound bacteria agent is composed of Lactobacillus plantarum 550 bacteria powder and Lactobacillus Brucella 225 bacteria powder according to the weight ratio 65~70:30~35 formulated lactic acid compound bacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com