High-melt-strength propylene/ethylene copolymer and preparation method thereof

A technology of ethylene copolymer and high melt strength, which is applied in the preparation of propylene/ethylene random copolymer and the field of high melt strength propylene/ethylene random copolymer, can solve the problem that supermolecules cannot be prepared and mechanical properties cannot be obtained. Properties and Processability of Propylene Polymers and Other Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

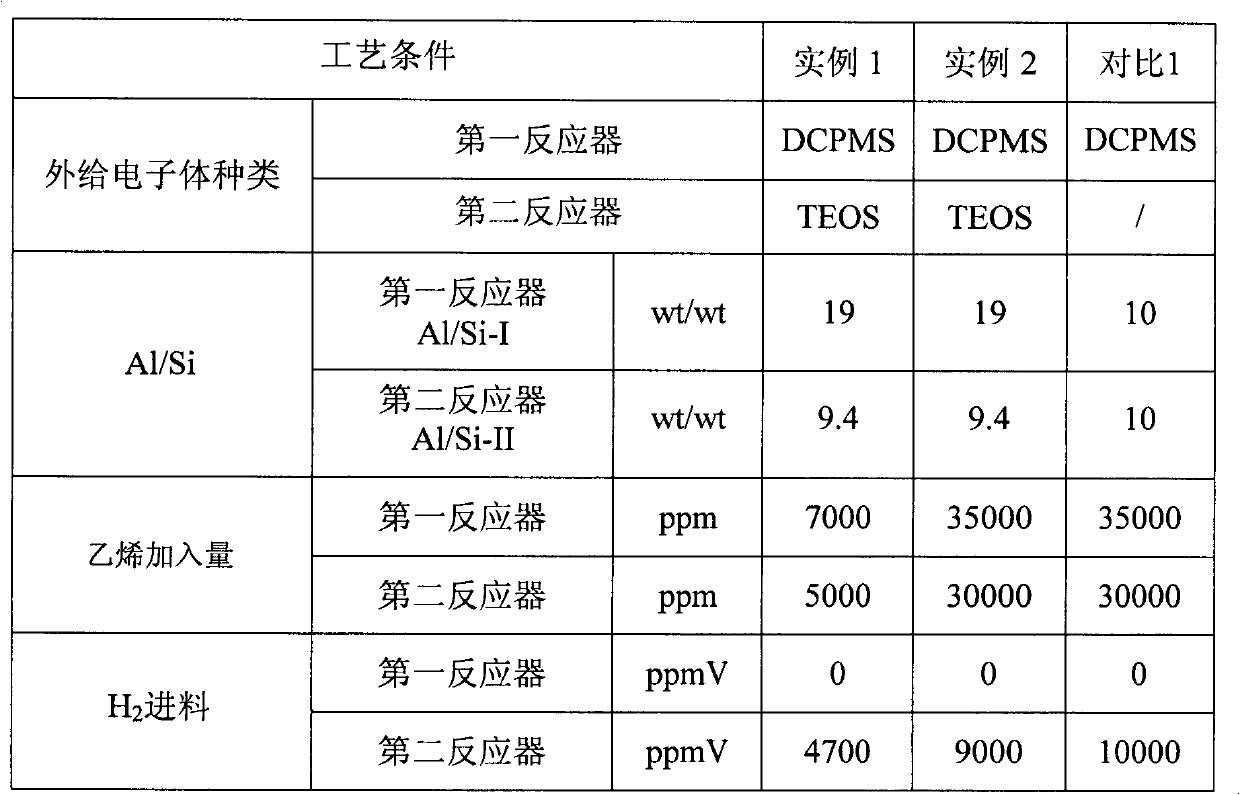

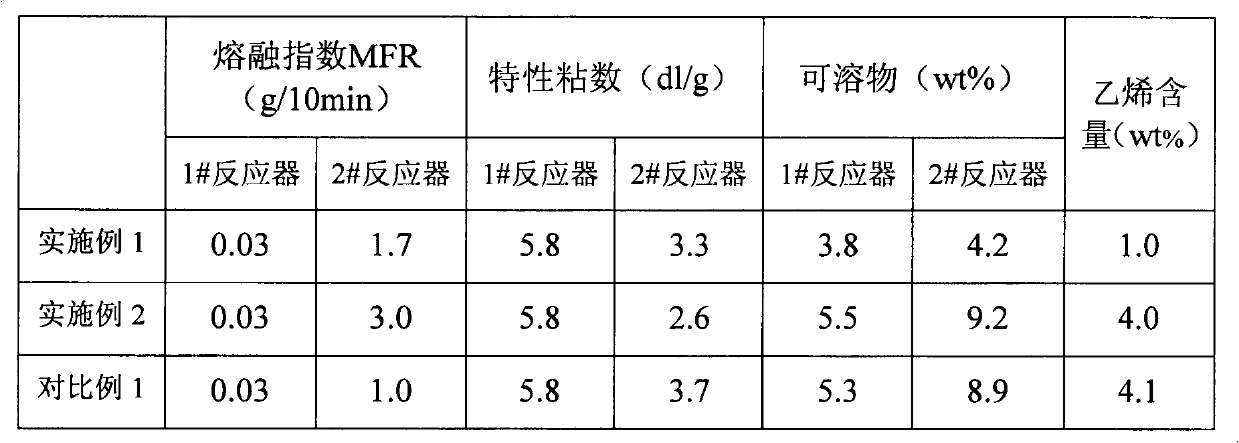

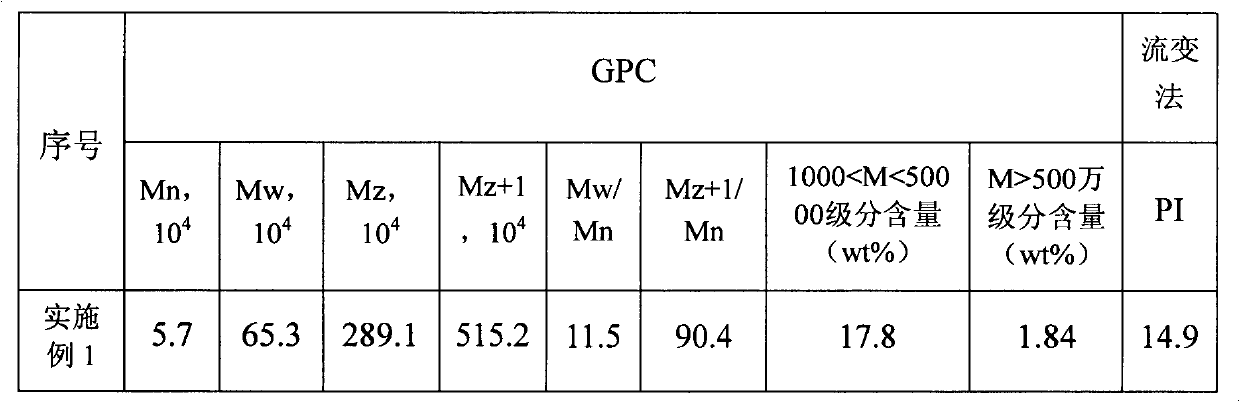

Embodiment 1

[0069] The polymerization reaction was carried out on a polypropylene pilot plant. Its main equipment includes prepolymerization reactor, first loop reactor and second loop reactor. Polymerization method and steps are as follows:

[0070] (1) Prepolymerization reaction:

[0071] The main catalyst (titanium-containing solid catalyst active component) is obtained by the method described in Example 1 of Chinese Patent CN93102795, its Ti content: 2.4wt%, Mg content 18.0wt%, di-n-butyl phthalate content: 13wt %.

[0072] The main catalyst, co-catalyst (triethylaluminum), and the first external electron donor (dicyclopentyldimethoxysilane, DCPMS) were pre-contacted at 10°C for 20 minutes, and then continuously added to the pre-polymerization reactor for pre-polymerization. In the polymerization reaction, the prepolymerization is carried out in the environment of the propylene liquid phase body, the temperature is 15° C., and the residence time is about 4 minutes. Under this condi...

Embodiment 2

[0081] With embodiment 1, only the ethylene addition in the first loop reactor becomes 35000ppmV; The ethylene addition in the second loop reactor is adjusted to 30000ppmV; Simultaneously, the hydrogen amount in the second loop reactor is adjusted to 9000ppmv .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com