LED structure comprising quantum barriers with gradient potential barrier heights and method for manufacturing LED structure

A technology of LED structure and potential barrier height, applied in the field of optoelectronics, can solve the problems of limited efficiency improvement and no improvement in hole transport, and achieve the effects of improving distribution, enhancing internal quantum efficiency and light output power, and improving binding capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

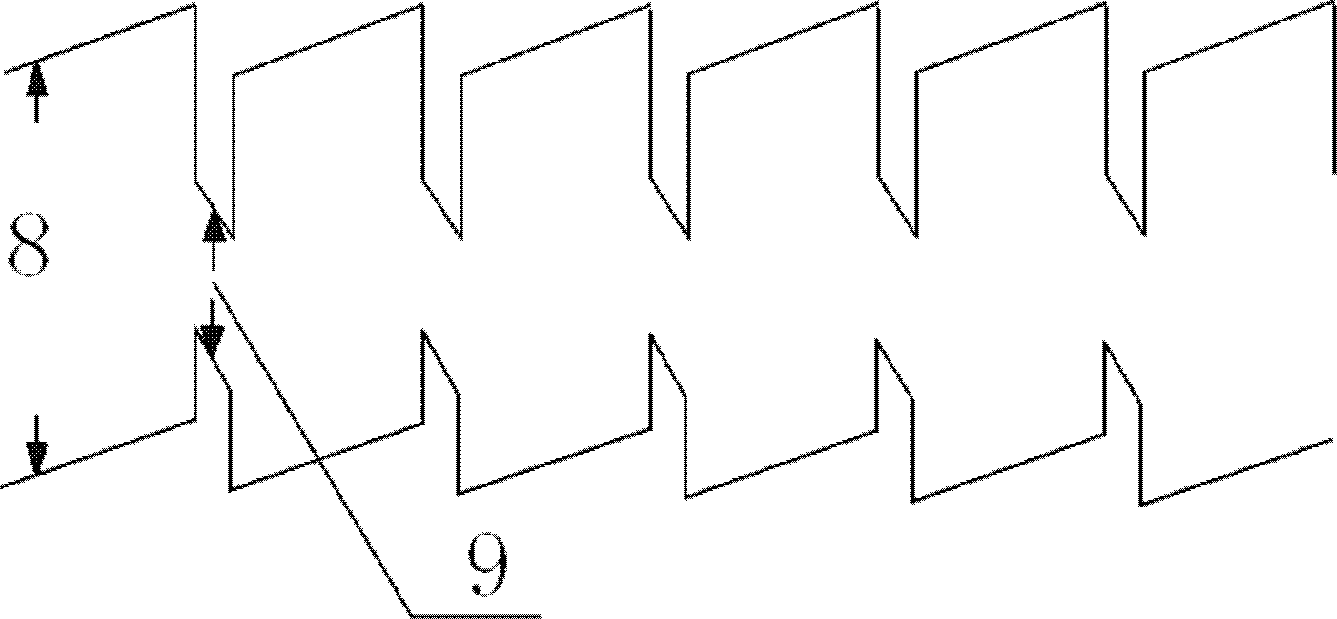

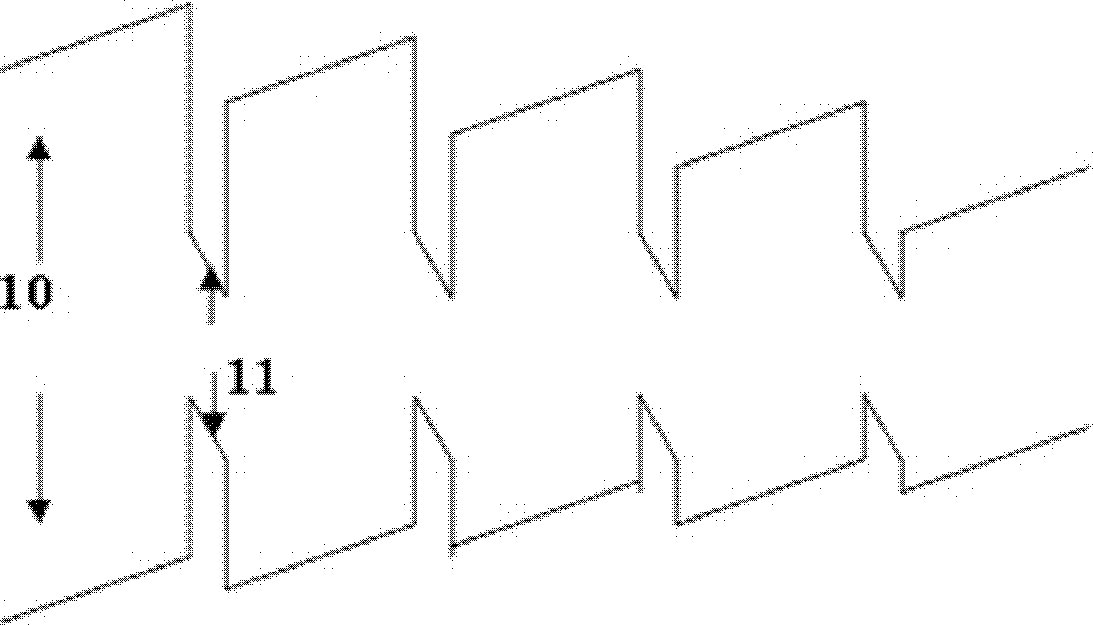

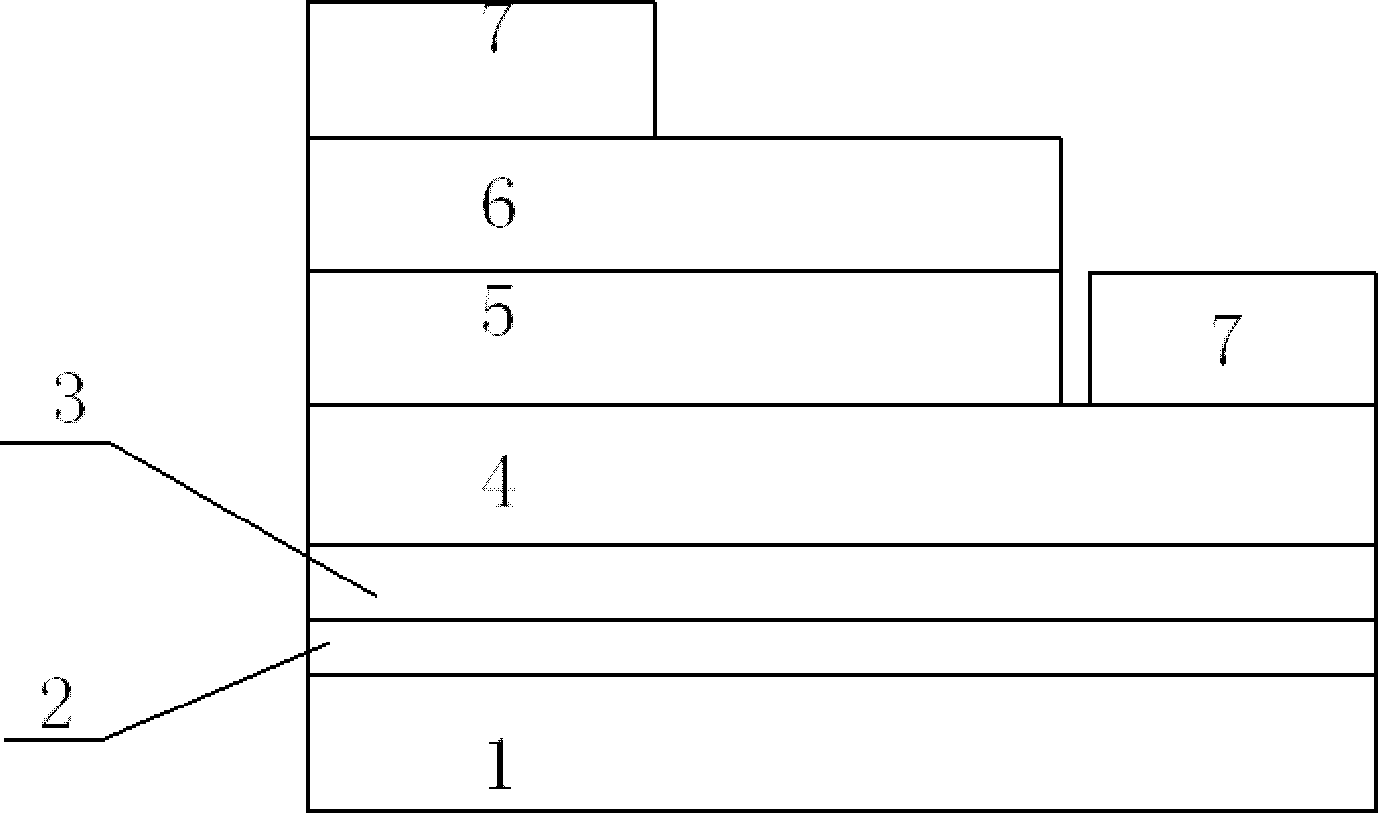

[0009] An LED structure using a quantum barrier with a gradient height of the potential barrier, including a nucleation layer, a buffer layer, an n-type conductive layer, a multi-quantum well layer and a p-type conductive layer on the substrate layer, and a p-type conductive layer on the n-type conductive layer. On the conductive layer are respectively ohmic contact layers; it is characterized in that, the described multi-quantum well layers are alternately grown Al with a thickness of 2-20nm x Ga 1-x-y In y N-well and Al with a thickness of 10-30nm u Ga 1-u-v In v N barriers, 2-30 repetition periods; among them, 0u Ga 1-u-v In v N, the value of u and v will meet the following conditions: make the potential barrier height of quantum barrier (that is, the forbidden band width) gradually reduce from the n side to the p side; and the forbidden band width of the quantum barrier is greater than the forbidden band width of the quantum well material . According to the general ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com