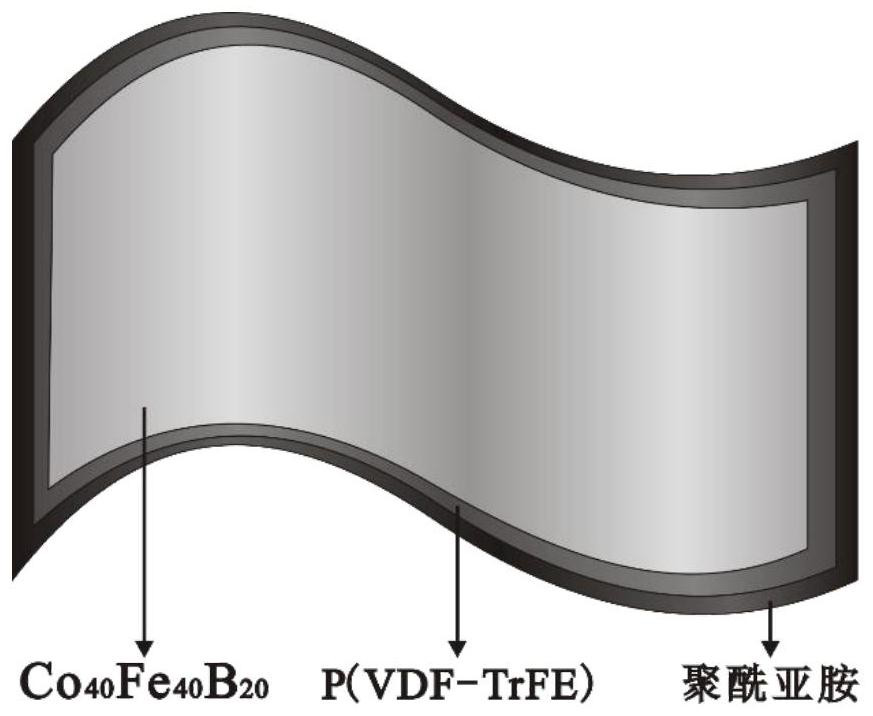

Graphene-doped full-flexible magnetoelectric heterojunction and preparation method thereof

A fully flexible, graphene technology, applied in the parts of electromagnetic equipment, the manufacture/processing of electromagnetic devices, the selection of materials, etc. problems, to achieve the effect of selectable device structure, controllable number of graphene layers, and reduced electric field modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

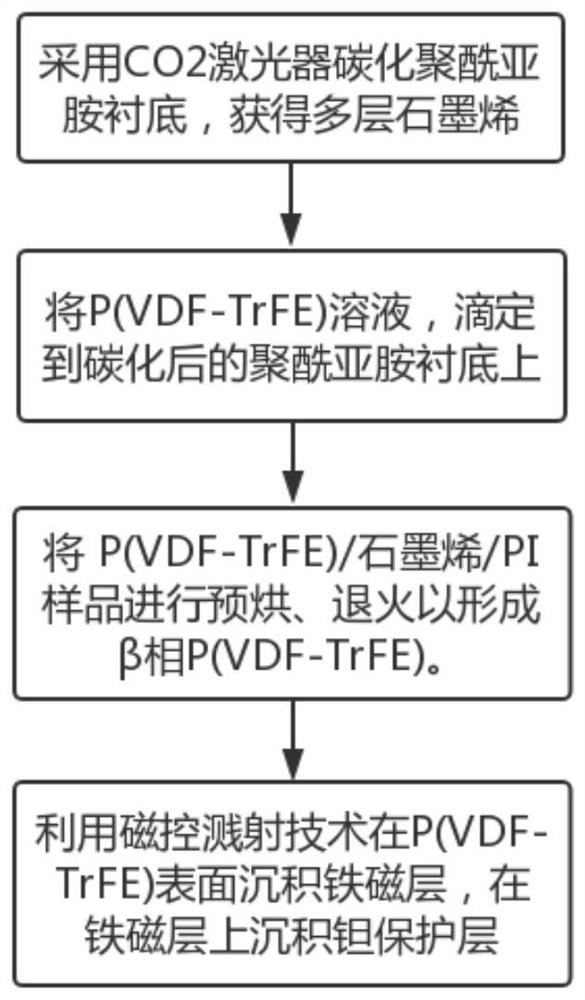

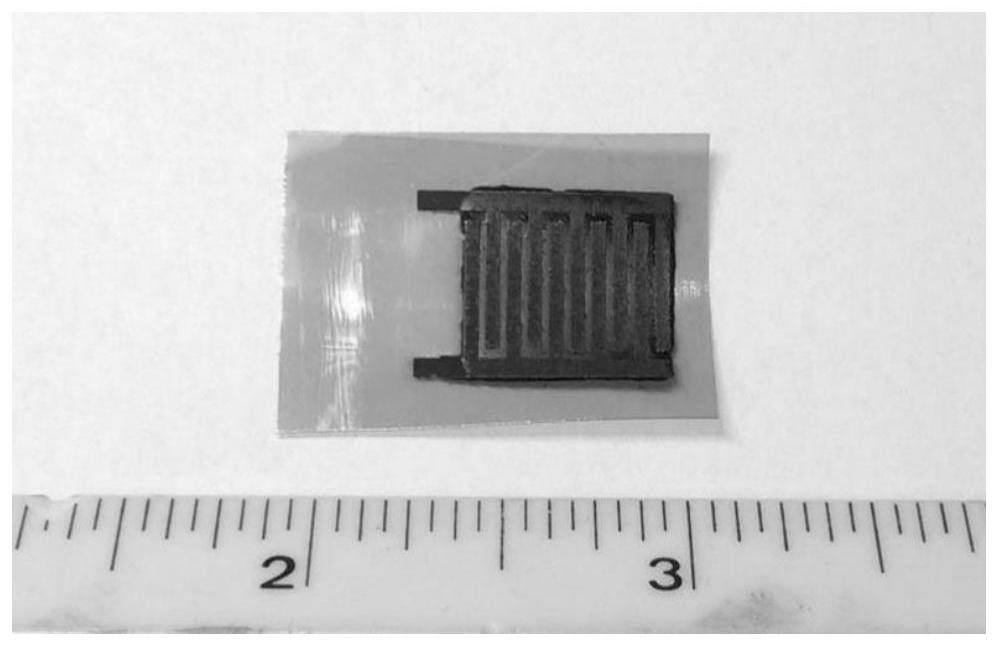

[0029] A preparation method of graphene-doped fully flexible magnetoelectric heterojunction, such as figure 2 shown, including the following steps:

[0030] Step 1. Paste the polyimide substrate with adhesive on one side on the iron sheet, and clean it with alcohol or the like.

[0031] Step 2, using CO 2 The laser engraving machine carbonizes the polyimide substrate, and its specific process conditions are: the laser current is 3.5mA, and the laser scanning speed is 100mm / s. The carbonized material was confirmed to be multi-layer graphene by Raman spectroscopy, and the graphene showed a foamy porous structure. The results were as follows: Figure 5 shown.

[0032] Step 3, disperse the P(VDF-TrFE) polymer powder with a ratio of 70 / 30mol% in dimethylformamide to form a P(VDF-TrFE) solution; use a pipette gun to quantitatively absorb P(VDF-TrFE) solution, dropped onto the surface of the graphene film.

[0033] Step 4, place the obtained P(VDF-TrFE) / graphene / PI sample in an...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is: in step 6, the ferromagnetic thin film Co 40 Fe 40 B 20 The working pressure is 0.9Pa, the sputtering power is 200W, the protective gas is an inert gas, an external magnetic field of 250Oe parallel to the direction of the substrate is provided during the sputtering process, the sputtering time is 10min, and the sputtering thickness is 200nm. The Co 40 Fe 40 B 20 The purity of the alloy target is not less than 99.99%. All the other steps are the same as in Example 1.

[0043] Figure 7 It is the magnetoelectric effect test curve of the flexible magnetoelectric heterojunction obtained in Example 2. The VSM curve shows that the squareness and magnetic properties of the magnetoelectric heterojunction are worse than those of Example 1, but the magnetoelectric effect of the heterojunction is still obvious. Under the electric field of 5V and 10V, its residual magnetization Mr changes.

[0044] Similarly, followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com