Preparing method for novel solid solution film/metal heterojunction photoelectrode

A solid solution and heterojunction technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of poor controllability, cumbersome powder collection and electrode preparation processes, etc., achieve rapid response, overcome powder collection and electrode preparation The process is cumbersome and the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

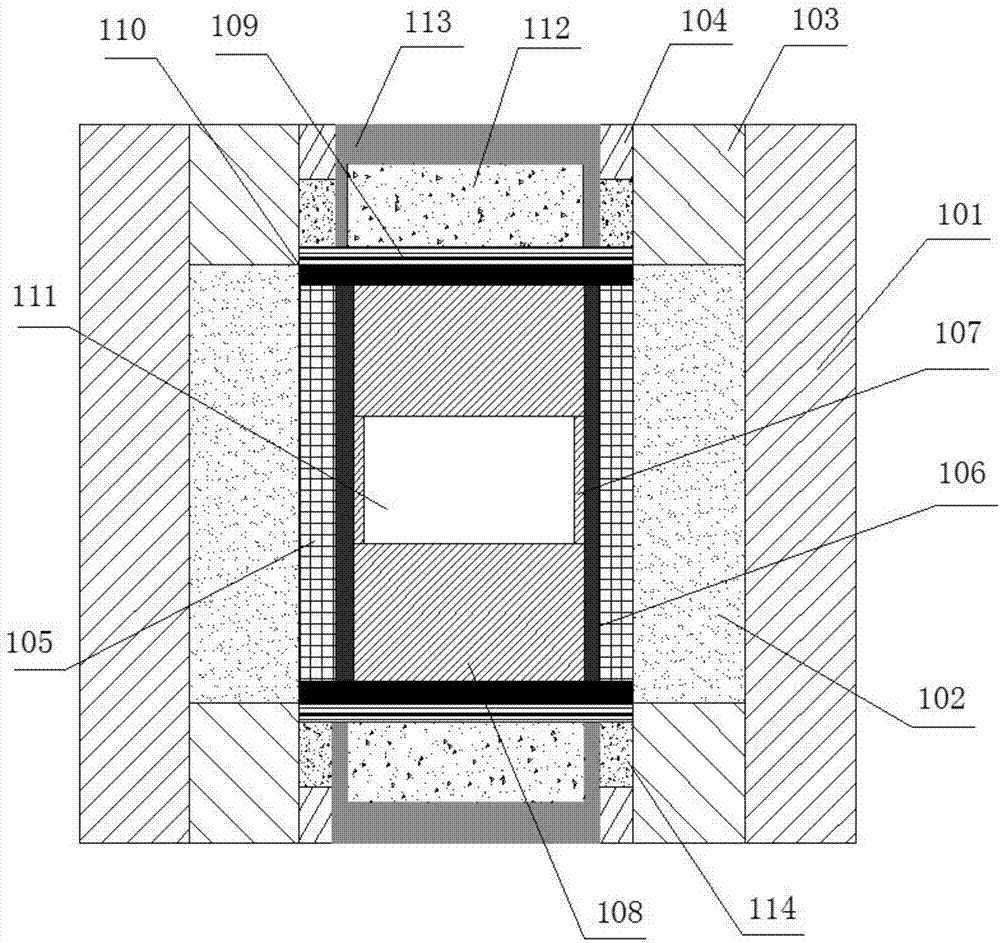

Image

Examples

Embodiment 1

[0032] In this embodiment, a novel solid solution film / metal heterojunction photoelectrode, the preparation process is as follows:

[0033] The metal nickel sheet with a thickness of 0.5mm was punched into a φ12mm disc, and then subjected to ultrasonic treatment in deionized water, acetone, isopropanol and absolute ethanol for 10 minutes, and then in N 2 Blow dry and set aside;

[0034] According to solid solution Bi 2 MoO 6 Composition, weigh a certain amount of Bi according to the molar ratio of 1:1 2 O 3 And MoO 6 The powder is the raw material. After mixing thoroughly, grind the mixture to 600 mesh, then add a certain volume of absolute ethanol to the mixture under stirring conditions until the slurry does not stick to the stirring paddle, then fully stir to form a uniform slurry, and then take a certain amount Coat the slurry uniformly on the metal nickel sheet after the above treatment by volume to form a solid solution film layer with a thickness of 0.2mm, and dry it at 60°C ...

Embodiment 2

[0040] In this embodiment, a novel solid solution film / metal photoelectrode, the preparation process is as follows:

[0041] The metal titanium sheet with a thickness of 0.3mm was punched into a φ12mm disc, and then subjected to ultrasonic treatment in deionized water, acetone, isopropanol and absolute ethanol for 10 minutes, and then in N 2 Blow dry and set aside;

[0042] According to solid solution Bi 2 WO 6 Composition, weigh a certain amount of Bi according to the molar ratio of 1:1 2 O 3 And WO 3 The powder is the raw material. After mixing thoroughly, grind the mixture to 600 mesh, then add a certain volume of absolute ethanol to the mixture under stirring conditions until the slurry does not stick to the stirring paddle, then fully stir to form a uniform slurry, and then take a certain amount Coat the slurry uniformly on the metal titanium sheet after the above treatment by volume to form a solid solution film with a thickness of 0.2mm, and dry it at 80°C for 5 hours to obta...

Embodiment 3

[0046] In this embodiment, a novel solid solution film / metal photoelectrode, the preparation process is as follows:

[0047] The metal Ag sheet with a thickness of 0.6mm was punched into a φ12mm disc, and then subjected to ultrasonic treatment in deionized water, acetone, isopropanol, and absolute ethanol for 10 minutes, and then in N 2 Blow dry and set aside;

[0048] According to solid solution K 4 Ce 2 Ta 10 O 30 Composition, weigh a certain amount of K according to the molar ratio of 2:1:5 2 O, Ce 2 O 3 And Ta 2 O 5 The powder is the raw material. After mixing thoroughly, grind the mixture to 600 mesh, then add a certain volume of absolute ethanol to the mixture under stirring conditions until the slurry does not stick to the stirring paddle, then fully stir to form a uniform slurry, and then take a certain amount Coat the slurry uniformly on the metal Ag sheet after the above treatment by volume to form a solid solution film layer with a thickness of 0.15mm, and dry it at 75°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com