Method for preparing cadmium sulfide or zinc sulfide hollow nano diamonds by using non-template method

A hollow nano, non-template technology, applied in the nano field, can solve the problems of limited output, complex process, harsh preparation conditions, etc., and achieve the effect of simple operation, mild reaction conditions, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 2 mmol of cadmium chloride and 2 mmol of sulfur powder, add them into 500 ml of tetrahydrofuran, ultrasonically disperse for 120 min, and ultrasonic power is 400 W; (2) Weigh out 2 mmol of sodium borohydride, add into In 500 ml of tetrahydrofuran, ultrasonically disperse for 120 min with ultrasonic power of 400 W; (3) Add the solution obtained in step (2) dropwise to the solution obtained in step (1), and continue the ultrasonic reaction for 120 min with ultrasonic power of 400 W; (4) The precipitate obtained in step (3) was centrifuged 5 times with absolute ethanol, and the obtained product was vacuum-dried at 20°C for 24 h.

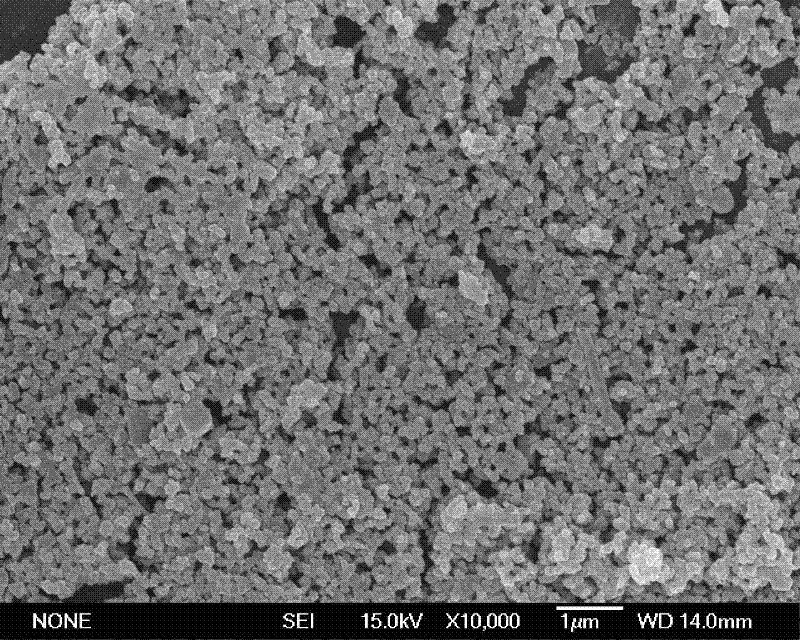

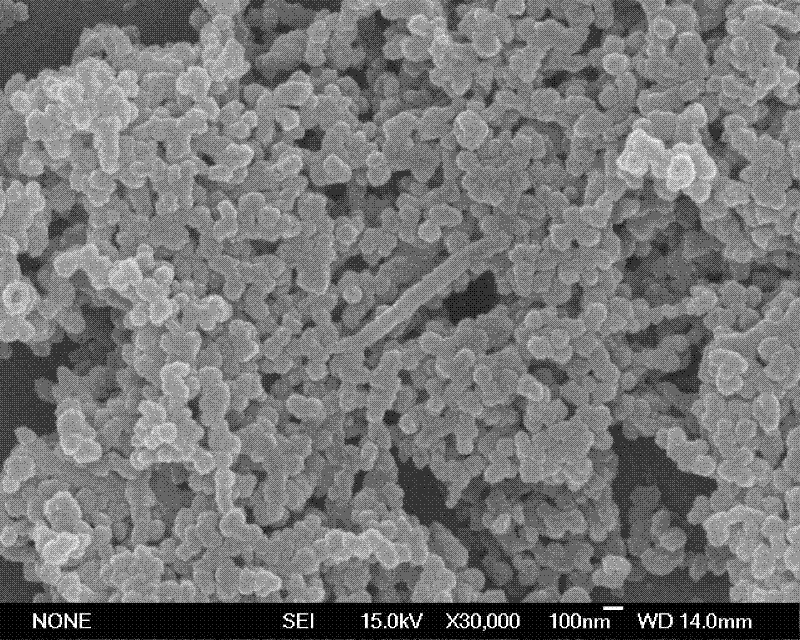

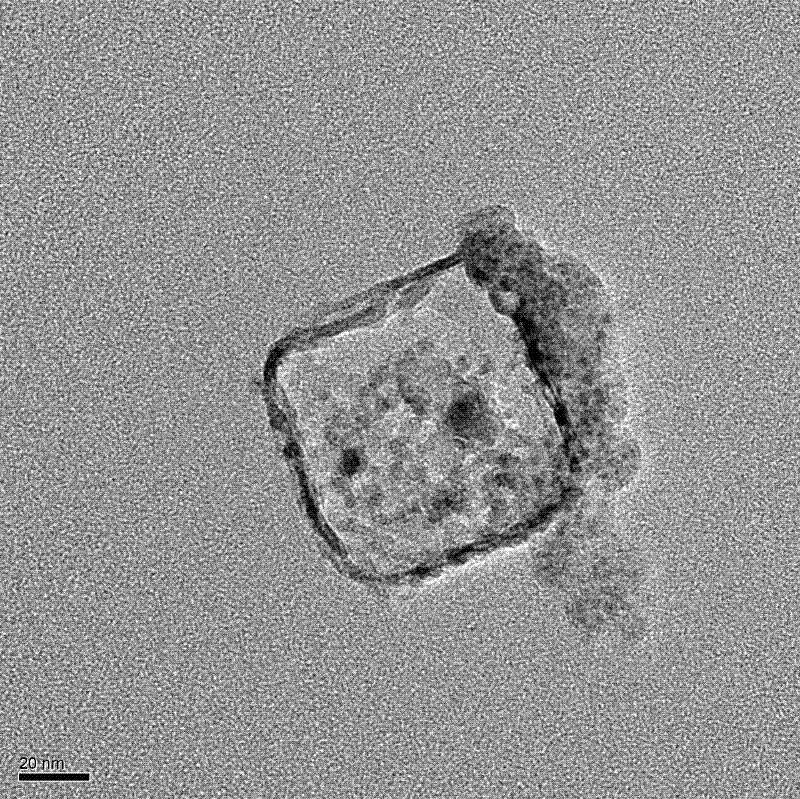

[0022] figure 1 and figure 2 The transmission electron micrographs and scanning electron micrographs of the prepared cadmium sulfide are respectively. It can be seen from the figure that the cadmium sulfide has a hollow nano-square structure, and the particle size is below 100 nm.

Embodiment 2

[0024] (1) Weigh 2 mmol of cadmium nitrate and 2 mmol of sulfur powder, add to 500 ml of tetrahydrofuran, ultrasonically disperse for 120 min, ultrasonic power 100 W; (2) weigh 2 mmol of sodium borohydride, add to 500 In ml of tetrahydrofuran, ultrasonically disperse for 120 min, ultrasonic power 100 W; (3) Add the solution obtained in step (2) dropwise to the solution obtained in step (1), continue ultrasonic reaction for 120 min, ultrasonic power 100 W; ( 4) The precipitate obtained in step (3) was centrifuged 5 times with absolute ethanol, and the obtained product was vacuum-dried at 200°C for 1 h. The result is similar to Example 1.

Embodiment 3

[0026] (1) Weigh 2 mmol of cadmium acetate and 2 mmol of sulfur powder, add to 300 ml of tetrahydrofuran, ultrasonically disperse for 60 min, ultrasonic power 200 W; (2) weigh 2 mmol of sodium borohydride, add to 300 In ml of tetrahydrofuran, ultrasonically disperse for 60 min, ultrasonic power 200 W; (3) Add the solution obtained in step (2) dropwise to the solution obtained in step (1), continue ultrasonic reaction for 60 min, ultrasonic power 200 W; ( 4) The precipitate obtained in step (3) was centrifuged 5 times with absolute ethanol, and the obtained product was vacuum-dried at 100°C for 12 h. The result is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com