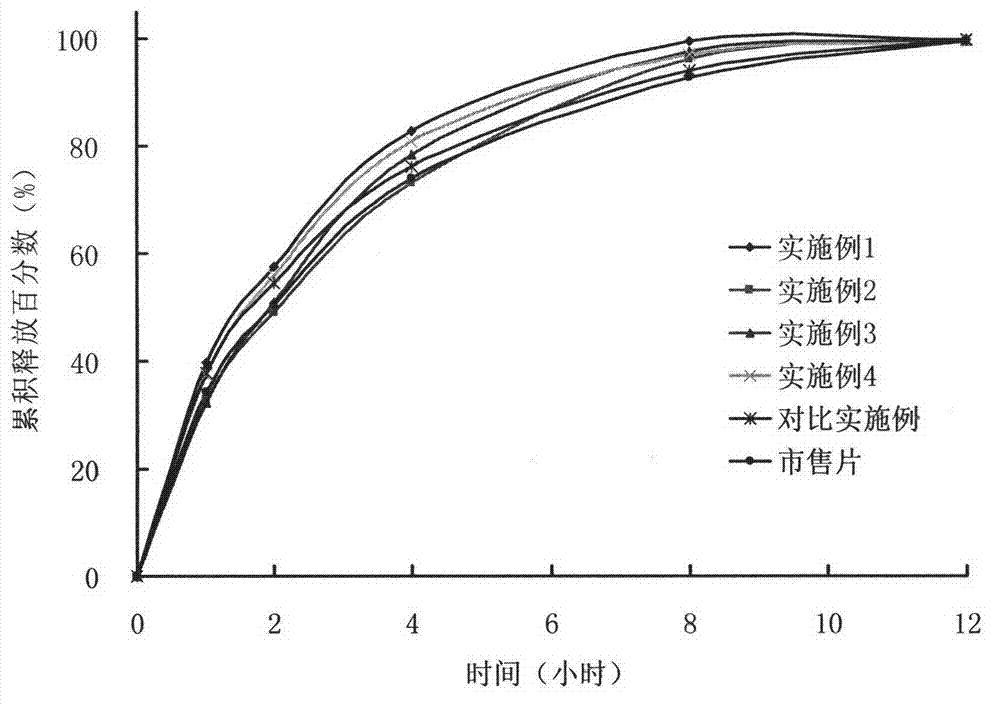

High-stability sustained-release tablet prepared by using hydroxy propyl cellulose

A hydroxypropyl cellulose, using hydroxypropyl technology, applied in the field of sustained-release tablets, can solve the problems of increased hydrochloride, difficulty in ensuring that related substances meet quality standards, poor stability of sustained-release tablets, etc., to achieve the reduction of koji hydrochloride. Degradation of metazine, improvement of product stability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preferred preparation method of the high-stability sustained-release tablet prepared by the present invention using hydroxypropyl cellulose comprises two kinds, and the first comprises the following steps:

[0063] (i) Mix 5-40 parts by weight of trimetazidine hydrochloride, 10-85 parts by weight of hydroxypropyl cellulose and a filler, add a binder, and make a soft material,

[0064] (ii) granulating, drying, sizing, drying and tableting the soft material to prepare trimetazidine hydrochloride sustained-release tablets.

[0065] Any method known in the field of formulation can be used to carry out the steps of mixing, preparing the soft material, granulating, drying, sizing, drying or tableting the soft material.

[0066] The second preparation method is to put all the raw and auxiliary materials in a container, mix them uniformly, and then perform tablet compression.

[0067] The main advantages of the present invention are:

[0068] 1. A steady-release trimetaz...

Embodiment 1

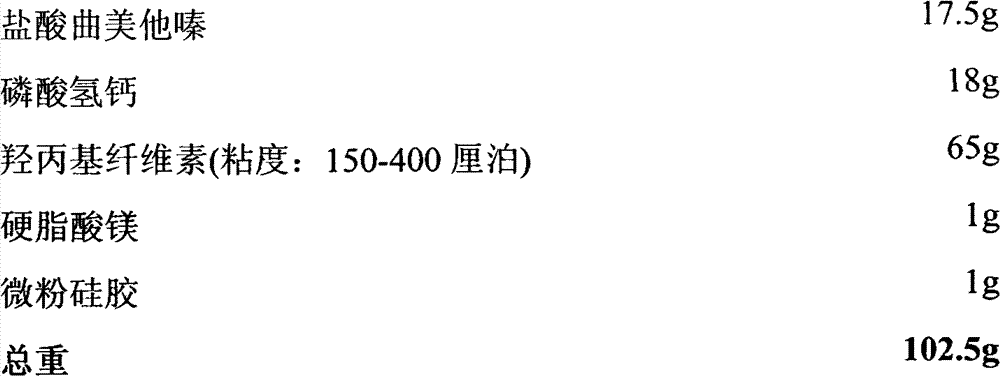

[0076] Preparation of Trimetazidine Hydrochloride Sustained Release Tablet 1

[0077] 1000 pieces

[0078]

[0079] Preparation:

[0080] Grind trimetazidine hydrochloride, hydroxypropyl cellulose (viscosity: 150-400 centipoise), and calcium hydrogen phosphate, pass through an 80-mesh sieve, and mix well. Add appropriate amount of water during stirring to granulate, dry and granulate. Then, add magnesium stearate and micropowder silica gel to the dry granules after granulation, put them in a mixer and mix them evenly. Tablet, get 1000 trimetazidine hydrochloride sustained-release tablets 1.

Embodiment 2

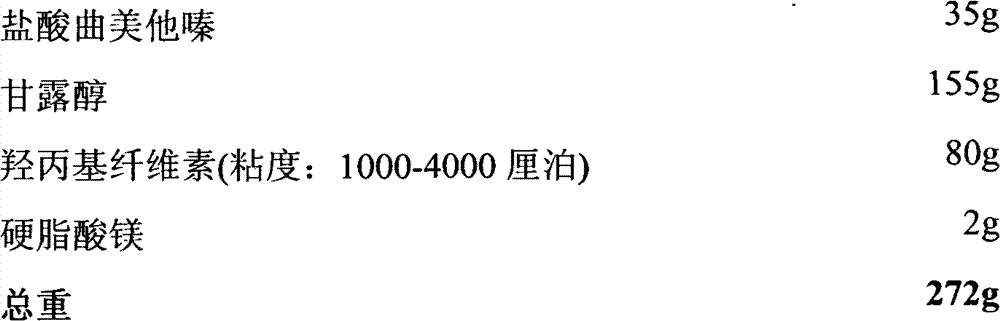

[0082] Preparation of Trimetazidine Hydrochloride Sustained Release Tablet 2

[0083] 1000 pieces

[0084]

[0085] Preparation:

[0086] Grind trimetazidine hydrochloride, hydroxypropyl cellulose (viscosity: 1000-4000 centipoise) and mannitol, pass through an 80-mesh sieve, and mix well. Add appropriate amount of water during stirring to granulate, dry and granulate. Add magnesium stearate to the above-mentioned dry granules after granulation, and put them in a mixer to mix evenly. Tablet, get 1000 trimetazidine hydrochloride sustained-release tablets 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com