Lost foam coating and preparation method thereof

A technology of lost foam and coating, which is applied in the direction of coating, manufacturing tools, casting and molding equipment, etc., which can solve the problems of poor coating adhesion and high manufacturing cost, and achieve the effect of strong adhesion, low use cost and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

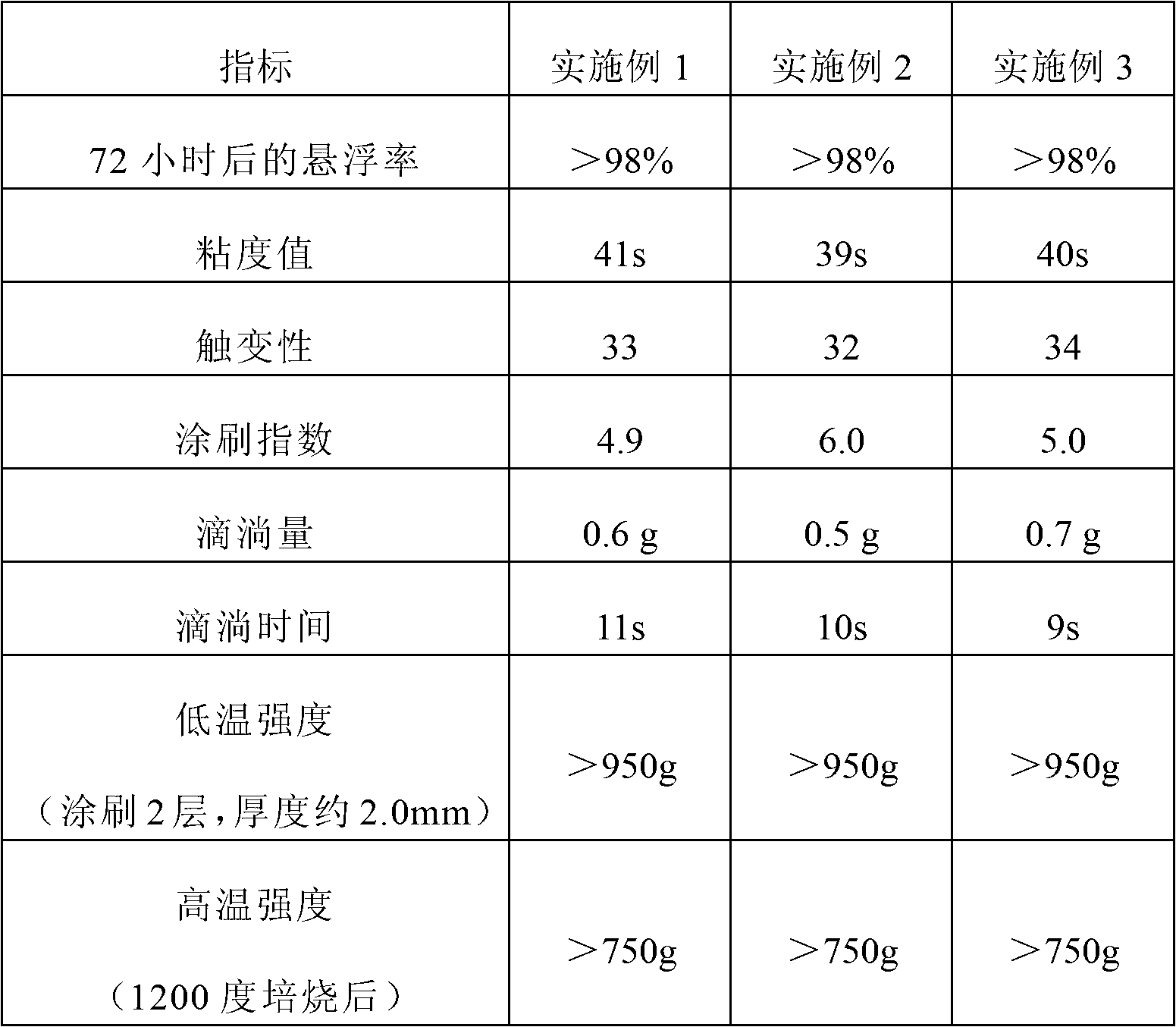

Examples

Embodiment 1

[0019] The ratio of each component of the lost foam coating is: 45 parts by weight of 200-mesh high-alumina bauxite clinker, 8 parts by weight of 200-mesh corundum powder, 25 parts by weight of 250-mesh quartz powder, 3 parts by weight of flake graphite, 1 part by weight of sodium bentonite, 1.5 parts by weight of CMC, 0.5 parts by weight of polyvinyl alcohol, 1 part by weight of silica sol, 0.3 parts by weight of T-80, 0.4 parts by weight of n-octanol, and 2 parts by weight of iron oxide red powder.

[0020] Follow the steps below to prepare lost foam coatings:

[0021] First, 1 part by weight of sodium bentonite is mixed with 8 parts by weight of water, and stirred at a high speed for 5 hours at a speed above 1000 rpm to form a bentonite slurry; meanwhile, 45 parts by weight of 200-mesh high-alumina bauxite clinker and 8 parts by weight of 200-mesh bauxite clinker are taken. Corundum powder, 25 parts by weight of 250-mesh quartz powder, and 3 parts by weight of flake graphit...

Embodiment 2

[0025] The ratio of each component of the lost foam coating is: 50 parts by weight of 250 mesh high alumina clinker, 10 parts by weight of 230 mesh corundum powder, 20 parts by weight of 250 mesh quartz powder, 5 parts by weight of flake graphite, 2 parts by weight of sodium bentonite, 1 part by weight of CMC, 1 part by weight of polyvinyl alcohol, 2 parts by weight of silica sol, 0.1 part by weight of T-80, 0.3 parts by weight of n-octanol, and 1 part by weight of iron oxide red powder.

[0026] Follow the steps below to prepare lost foam coatings:

[0027] First, mix 2 parts by weight of sodium bentonite with 10 parts by weight of water, and stir at a high speed above 1000 rpm for 6 hours to form a bentonite slurry; meanwhile, take 50 parts by weight of 250-mesh high-alumina bauxite clinker, 10 parts by weight of 230-mesh Corundum powder, 20 parts by weight of 250-mesh quartz powder, and 5 parts by weight of flake graphite were stirred evenly in a grinding device, and 60 par...

Embodiment 3

[0031] The ratio of each component of the lost foam coating is: 55 parts by weight of 300-mesh high-alumina bauxite clinker, 15 parts by weight of 250-mesh corundum powder, 23 parts by weight of 280-mesh quartz powder, 8 parts by weight of flake graphite, 3 parts by weight of sodium bentonite, 0.5 parts by weight of CMC, 1.5 parts by weight of polyvinyl alcohol, 3 parts by weight of silica sol, 0.2 parts by weight of T-80, 0.2 parts by weight of n-octanol, and 3 parts by weight of iron oxide red powder.

[0032] Follow the steps below to prepare lost foam coatings:

[0033] First, 3 parts by weight of sodium bentonite is mixed with 9 parts by weight of water, and stirred at a high speed above 1000 rpm for 7 hours to form a bentonite slurry; meanwhile, 55 parts by weight of 300-mesh high-alumina bauxite clinker, 15 parts by weight of 250-mesh Corundum powder, 23 parts by weight of 280-mesh quartz powder, and 8 parts by weight of flake graphite were stirred evenly in the grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com